Clutch Slave Cylinder for Hybrid Vehicles

A technology for clutch cylinders and hybrid vehicles, which is applied to fluid-driven clutches, clutches, and non-mechanical drive clutches. It can solve problems such as operational impact, pollution, and complex structure of the control oil circuit, and achieve pollution reduction, easy control, and positioning. simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

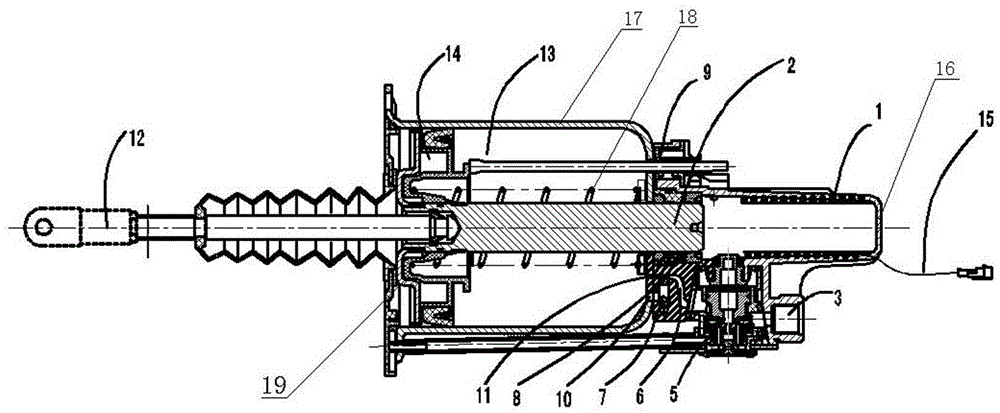

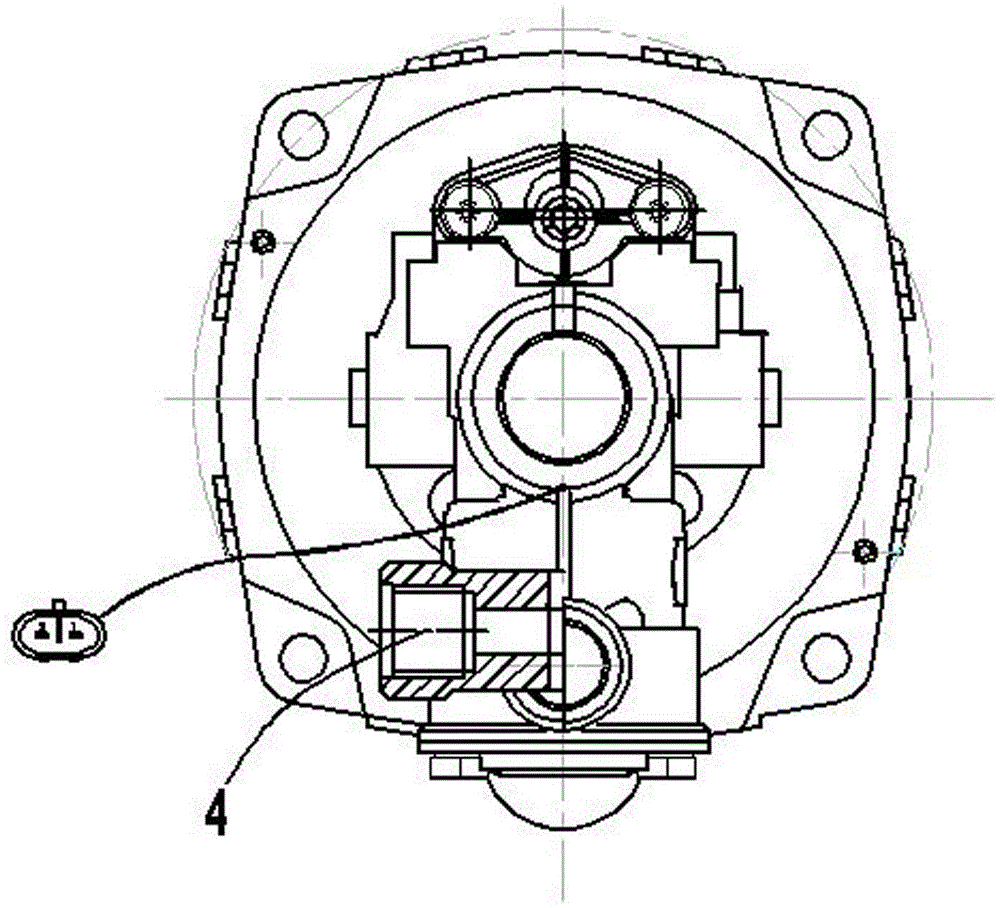

[0013] The embodiment of the hybrid vehicle clutch slave cylinder of the present invention: as Figure 1 ~ Figure 2 As shown, the hybrid vehicle clutch cylinder includes a booster cylinder 17, a booster cylinder piston 19 is arranged in the booster cylinder 17, and the booster cylinder piston 19 separates the booster cylinder 17 into a front cylinder and a rear cylinder. The piston 19 is fixedly connected with a piston rod 2 that can move back and forth with the piston 19 of the booster cylinder. The piston rod 2 is covered with a piston spring 18. The inner wall of the rear side is connected, and the front side of the booster cylinder piston 19 is provided with a clutch push rod 12. The clutch push rod 12 is coaxially arranged with the piston rod 2 and can move back and forth with the piston rod 2. The clutch push rod 12 and the booster cylinder piston 19 can be Slight rotation fit; also includes booster air inlet 3 and control air inlet 4, the booster air inlet 3 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com