A Microscopic Area Charge Injection and Quantitative Analysis Method in Nano-Silicon Floating Gate Structure

A technology of charge injection and nano-silicon, applied in measuring devices, scanning probe microscopy, instruments, etc., to achieve good repeatability and high detection resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] (1) Injection of microscopic regional charges in the nano-silicon floating gate structure

[0031] 1. Preparation of samples with nano-silicon floating gate structure

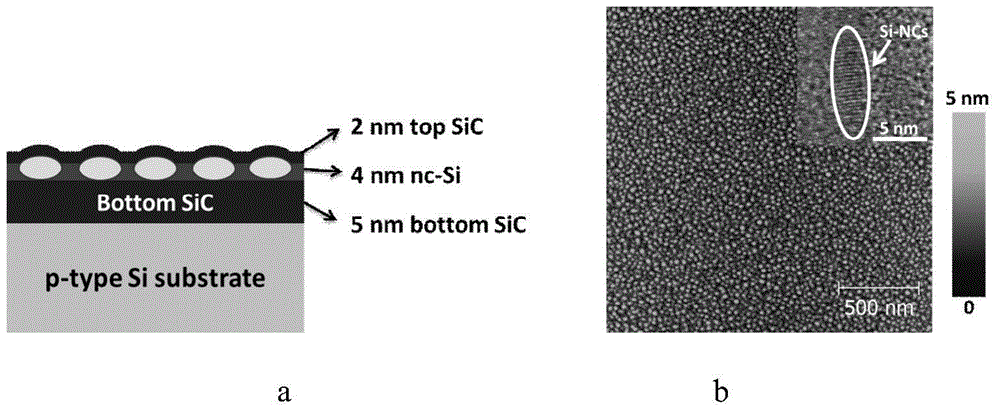

[0032] The nano-silicon floating gate structure sample is a silicon carbide / nano-silicon / silicon carbide (SiC / nc-Si / SiC) sandwich structure on a p-type single crystal silicon substrate (resistivity 1.5–3Ωcm), in which the thickness of the underlying silicon carbide is 5nm, the thickness of the nano-silicon layer is 4nm, and the top layer of silicon carbide is 2nm. For the charge injection test, the sample substrate was bonded to the test tray using conductive silver paste (Silver Paint), and finally the tray and the sample were placed in the operating room of the atomic force microscope.

[0033] 2. Charge injection of nano-silicon floating gate structure

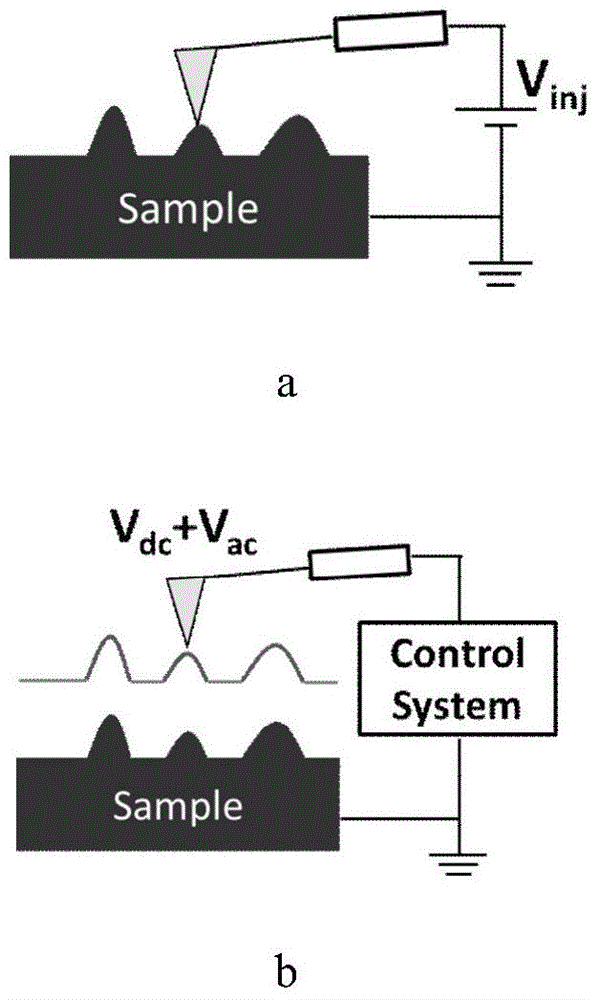

[0034] At room temperature and in a clean air atmosphere, let the atomic force microscope (Bruker, Germany, Nanoscope3D model) work in the tapping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com