Method for reducing air in core bag of capacitor

A technology of capacitors and core packs, applied in the field of capacitors, can solve problems such as unusable, achieve the effect of reducing air and stabilizing electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

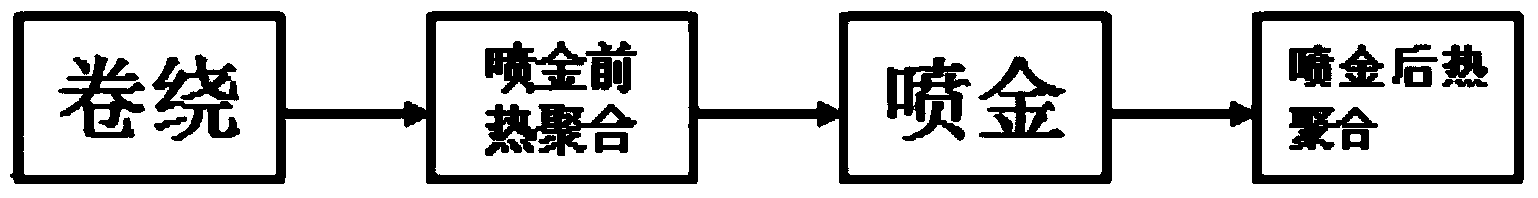

[0012] Such as figure 1 As shown, a method for reducing the air in the capacitor core package includes the following steps:

[0013] (1) First use a vernier caliper to measure whether the width of the metallized film of the upper and lower diaphragms is consistent, the error should be less than 0.1mm, check whether the diaphragm is deformed, and whether the cutting surface is smooth, and then wind it on the machine after meeting the requirements, and control the amount of misalignment in the test paper. Between 0.8mm and 1.0mm, and random inspection in the middle and late stages of winding;

[0014] (2) Then, when performing the first thermal polymerization, adjust the temperature to 70°C, and the polymerization time is 24 hours. If the temperature is too high, it will easily cause the section to fall. Pressure to avoid section lodging;

[0015] (3) Use dry compressed air when spraying gold again, the pressure is between 8Kg and 10Kg, the first pass is 10kg, and the next sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com