Method for forming shallow trench isolation structure

A technology of isolation structures and shallow trenches, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the difficulty of process uniformity control, poor isolation performance of shallow trench isolation structures, and affect the stability of semiconductor devices, etc. problem, to achieve good isolation effect, not easy to leak, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

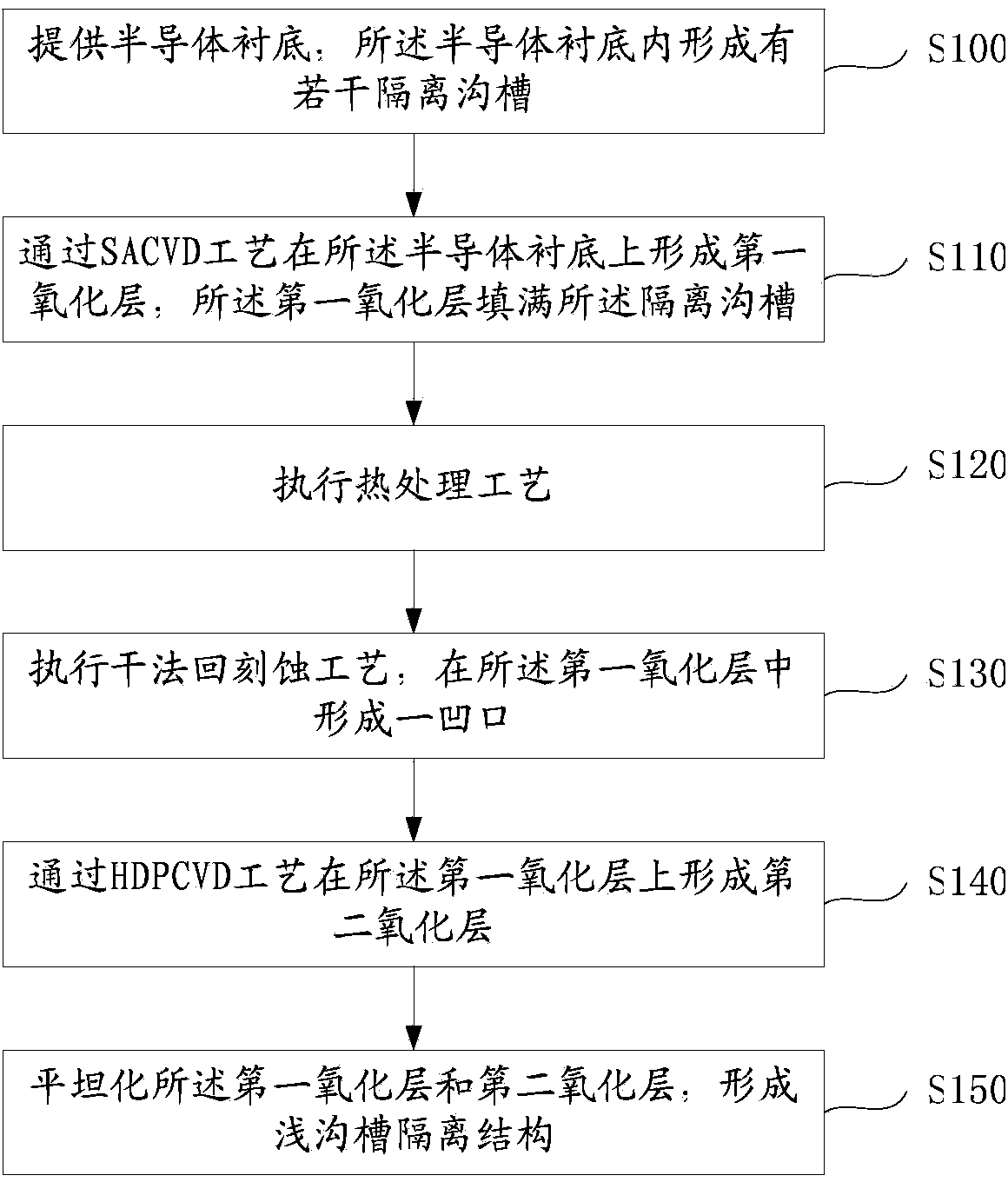

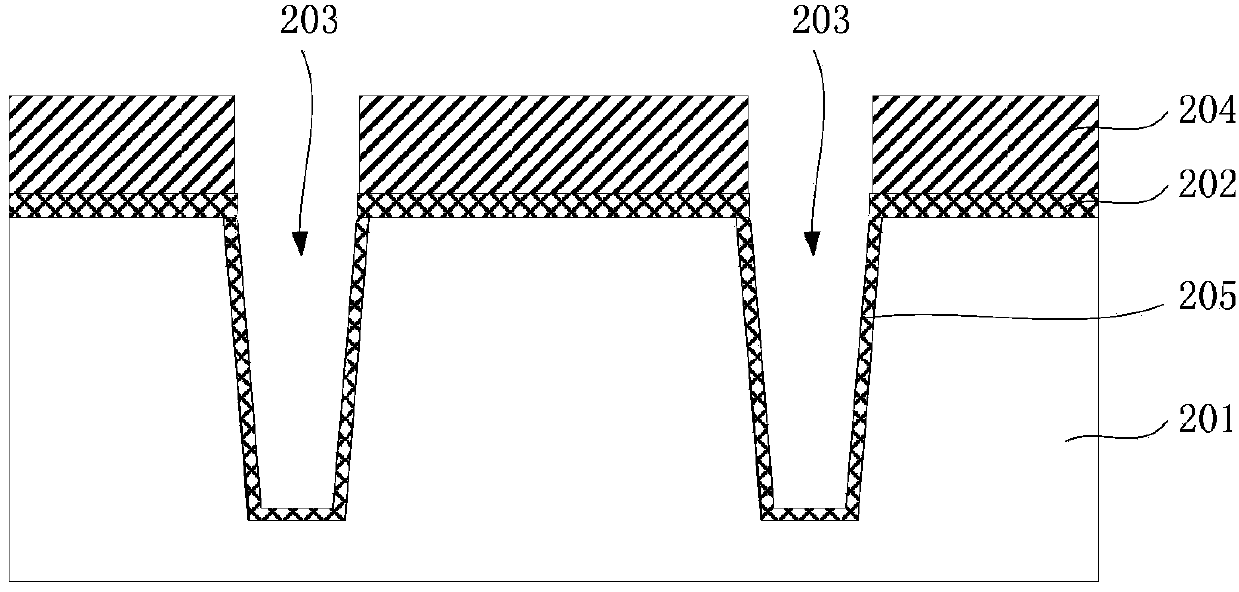

[0028] As described in the background art, with the continuous reduction of the feature size of semiconductor devices, the size of the shallow trench isolation structure used for device isolation also becomes smaller, and the aspect ratio of the isolation trench used to form the shallow trench isolation structure changes. When the oxide layer is filled in the isolation trench by the SACVD process, a fragile surface is likely to appear, resulting in poor isolation performance of the shallow trench isolation structure, and semiconductor devices including the shallow trench isolation structure are prone to leakage and poor stability. Therefore, in the present invention, after the first oxide layer is formed by the SACVD process, a dry etch-back process is performed to eliminate the fragile surface in the first oxide layer, and then the second oxide layer is formed by the HDPCVD process. In addition, a heat treatment process is performed after the first oxide layer is formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com