Integrated hydrogen production-hydrogen storage power generation system

An integrated, hydrogen storage technology, applied in hydrogen, circuits, fuel cells, etc., to achieve the effects of energy saving, convenient installation and use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

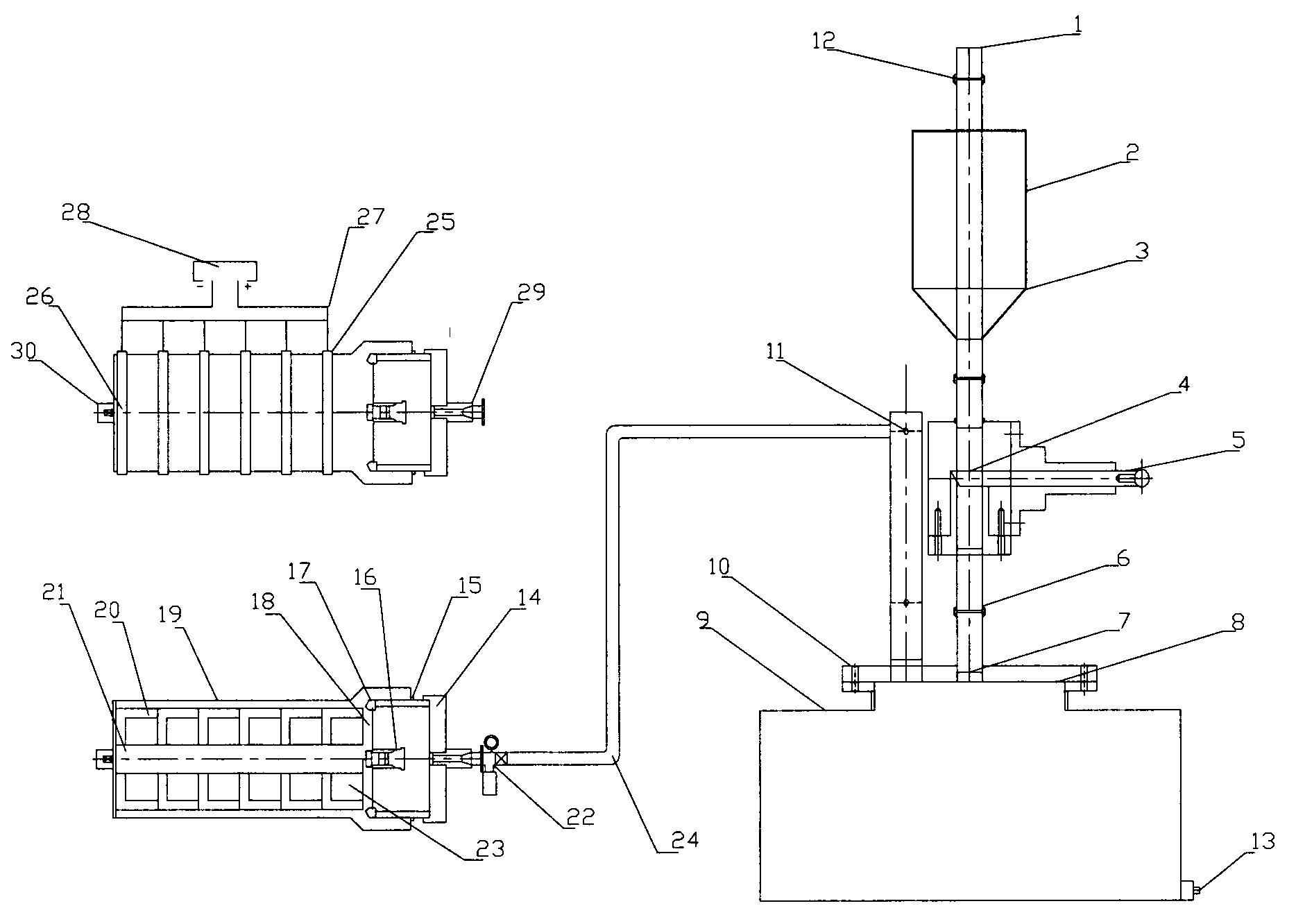

[0013] Disassemble the stocker 2 from the hydrogen reactor 9, then inject water into the reactor 9, fill the aluminum matrix compound in the storage bin 3, and reassemble the stocker 2 and the hydrogen reactor 9 , The two screw seals are connected by 10. The upper part of the stocker 2 is provided with a feeding port 1, and the discharge port 6 at the lower part of the stocker is provided with a valve 4 with a spring pull rod 5. When the hydrogen production device needs to be started, the valve 4 at the outlet 6 at the lower part of the stocker 2 is opened, so that the aluminum-based compound flows into the reactor 9 and reacts with water to quickly generate hydrogen, and the produced hydrogen is output from the hydrogen outlet 11, The gas valve 29 enters the stainless steel tank 19 through the gas pipeline 24, the gas reacts through the hydrogen storage alloy 23, and produces high-purity hydrogen through the filter 21 from the gas outlet valve 30. The thermoelectric semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com