Method and apparatus for classifying bulk materials

A bulk material and graded technology, applied in the field of graded bulk material, can solve the problems of unfavorable processing and operating costs, unsatisfactory bulk material production volume, troublesome operation, etc., and achieve the effect of simple assembly, increased production capacity, and improved conveying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

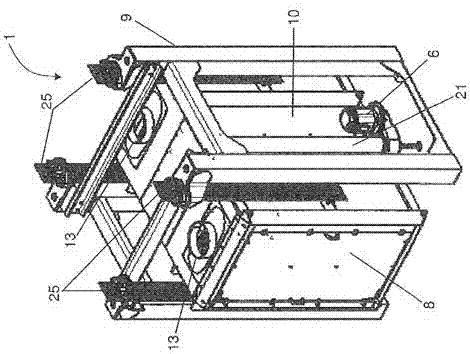

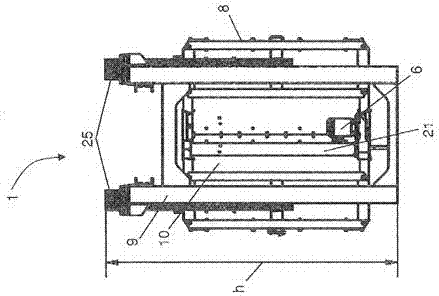

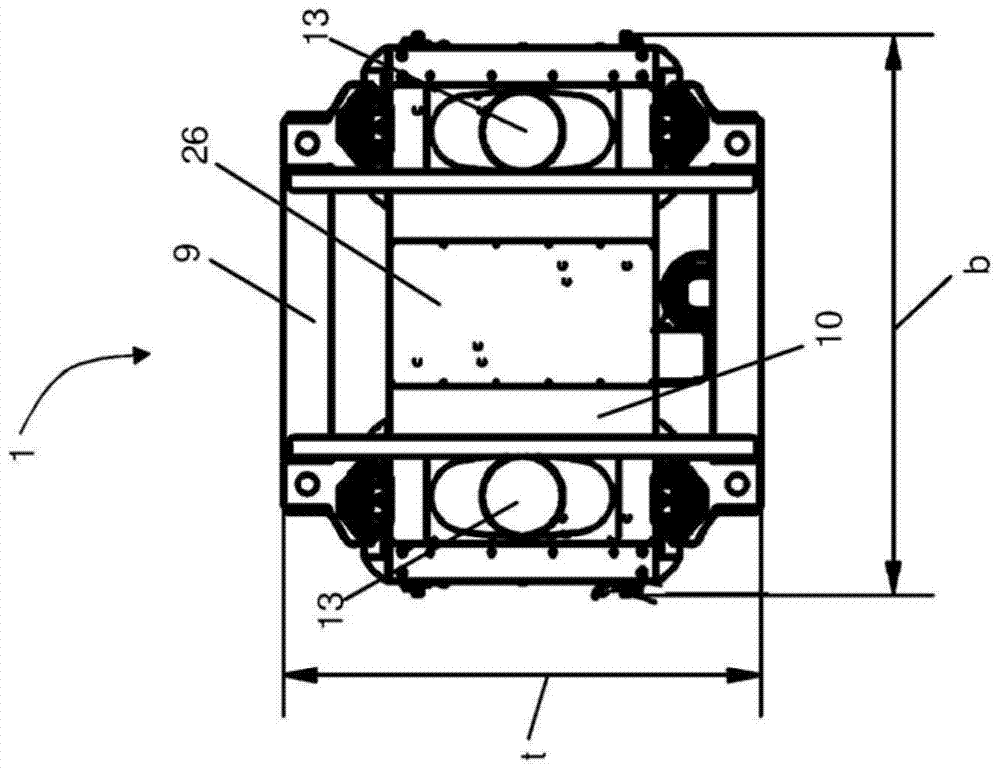

[0077] exist figure 1 The device 1 for classifying bulk material is shown in perspective view in . The device 1 has a housing 10 which is suspended on a frame 9 by means of rods 25 .

[0078] The housing 10 has a door 8 which can be opened to provide access to the housing interior, in which a sieve or a sieve pack (not shown here) for classifying the bulk material can be accommodated. The housing 10 has two inlets 13 through which the bulk material can be conveyed into the housing 10 and then classified in the housing 10 by means of a sieve or sieve stack not shown. Mounted on the housing 10 is the drive mechanism formed by the electric motor 6 and the coupling mechanism formed by the coupling shaft 21 .

[0079] During operation, the device 1 is set in an oscillating motion by the drive of the electric motor 6 via the coupling shaft 21 . This is achieved by driving vibrating masses (not shown here), which are located in the top or bottom of the housing 10 and are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com