Feeding structure of juice extractor

A juicer and feeding technology, applied in the field of juicer feeding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

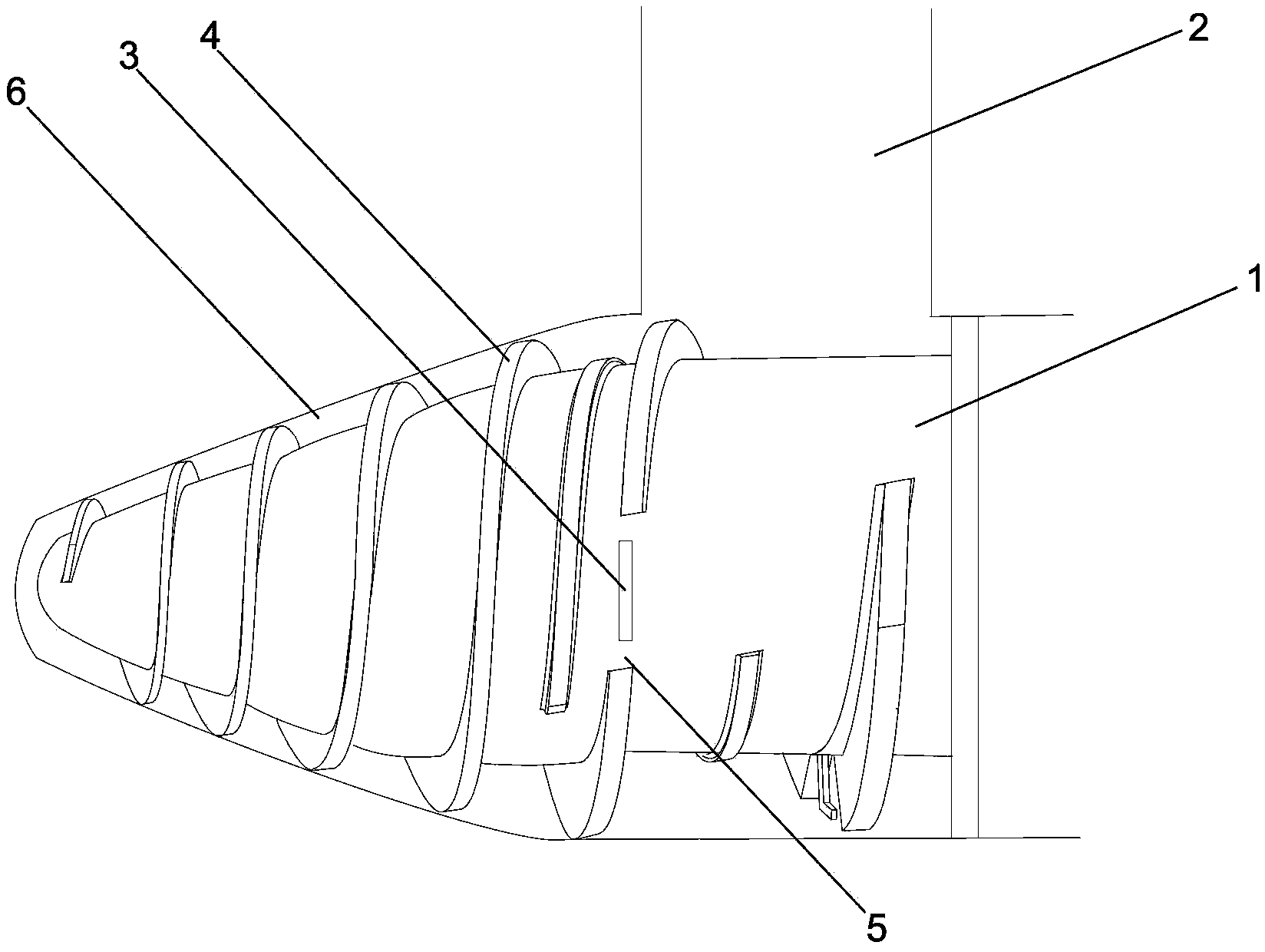

[0020] Such as figure 1 As shown, a feeding structure of a juice extractor includes a screw propeller 1, the screw propeller 1 is perpendicular to the feed barrel 2 of the juice extractor, and the screw propeller 1 includes a cylindrical food material entering section and a conical food material squeezing section There are two parts, the food entry section is facing the mouth of the feeding barrel 2, this section is the beginning of the food entering the inner cavity of the juicer, the food entry section receives the food fed from the outside and continues to transport the food to the rear, and the food squeezing section is The whole is located in the front section of the squeeze chamber 6 of the juice extractor, and the front section of the squeeze chamber 6 is also tapered to form a match with the food material pressing section. The food material entering section and the food pressing section are integrally formed. Feeding tooth 3, the feeding tooth is positioned at t...

Embodiment 2

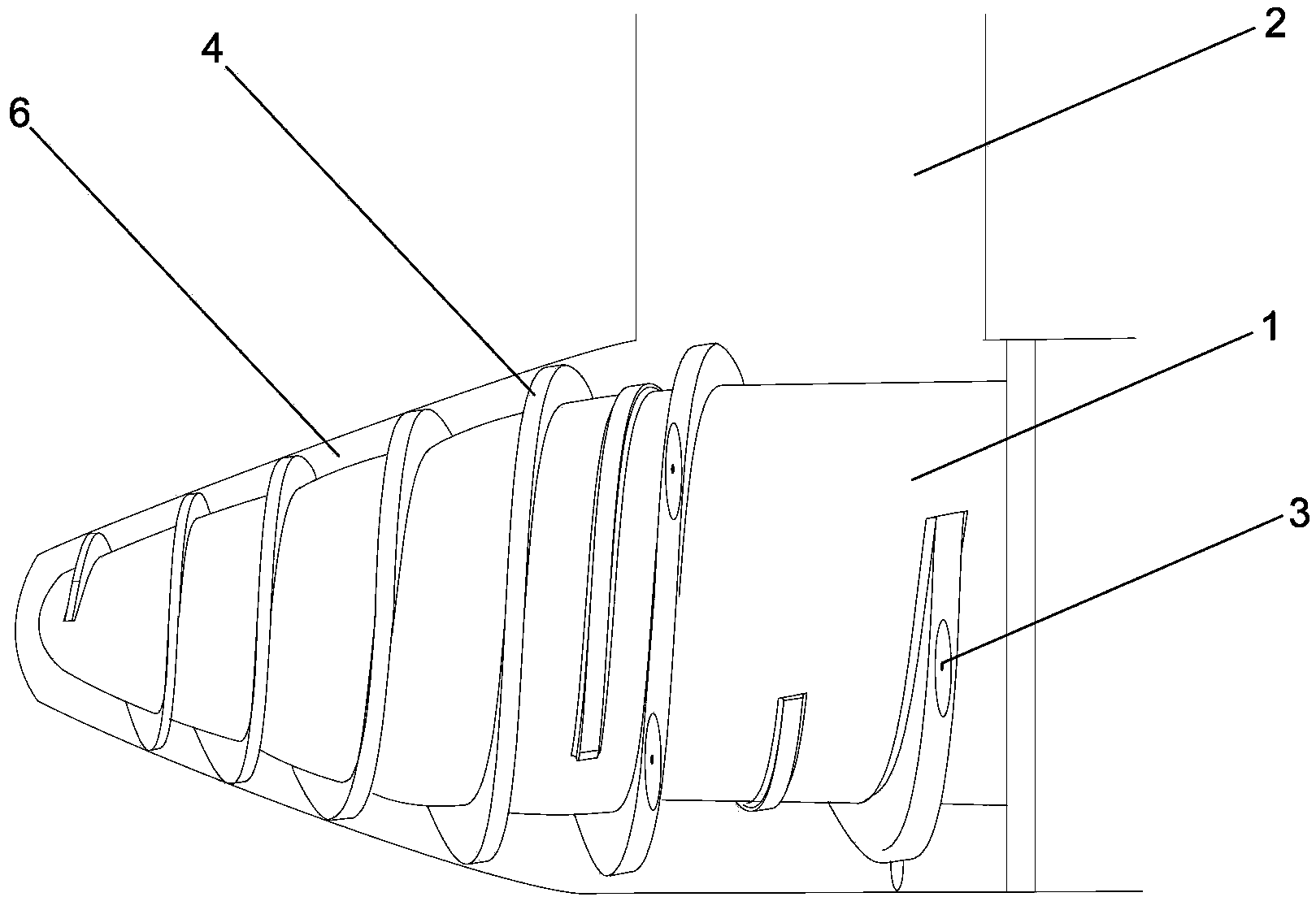

[0023] Such as figure 2 As shown, the spiral 4 at the material entry end of the screw propeller 1 is a continuous spiral, and the feeding teeth 3 are located on the spiral 4 . There are five feeding teeth, and the feeding teeth are triangular in shape. The section of the feeding tooth perpendicular to the height direction of the feeding tooth is jujube-shaped, and the long axis of the section is perpendicular to the axial direction of the screw propeller. All the other are with embodiment 1.

Embodiment 3

[0025] The helix at the material entry end of the screw propeller is an intermittent helix, and there are multiple interrupted notches on the helical path, and the feeding teeth are located in the interrupted notches. There are six feeding teeth, and the feeding teeth are triangular in shape. The section of the feeding tooth perpendicular to the height direction of the feeding tooth is jujube-shaped, and the long axis of the section is perpendicular to the axial direction of the screw propeller. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com