Roller coaster stand column structure and installation method

A roller coaster and column technology, which is applied in the field of roller coaster column structure and installation, can solve the problems that cannot meet the positioning accuracy of track column bolt connection, poor positioning accuracy of track column connection points, and cannot meet the safety of train operation, etc., to achieve no gap contact , high positioning accuracy, and the effect of improving the force condition of the column foot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

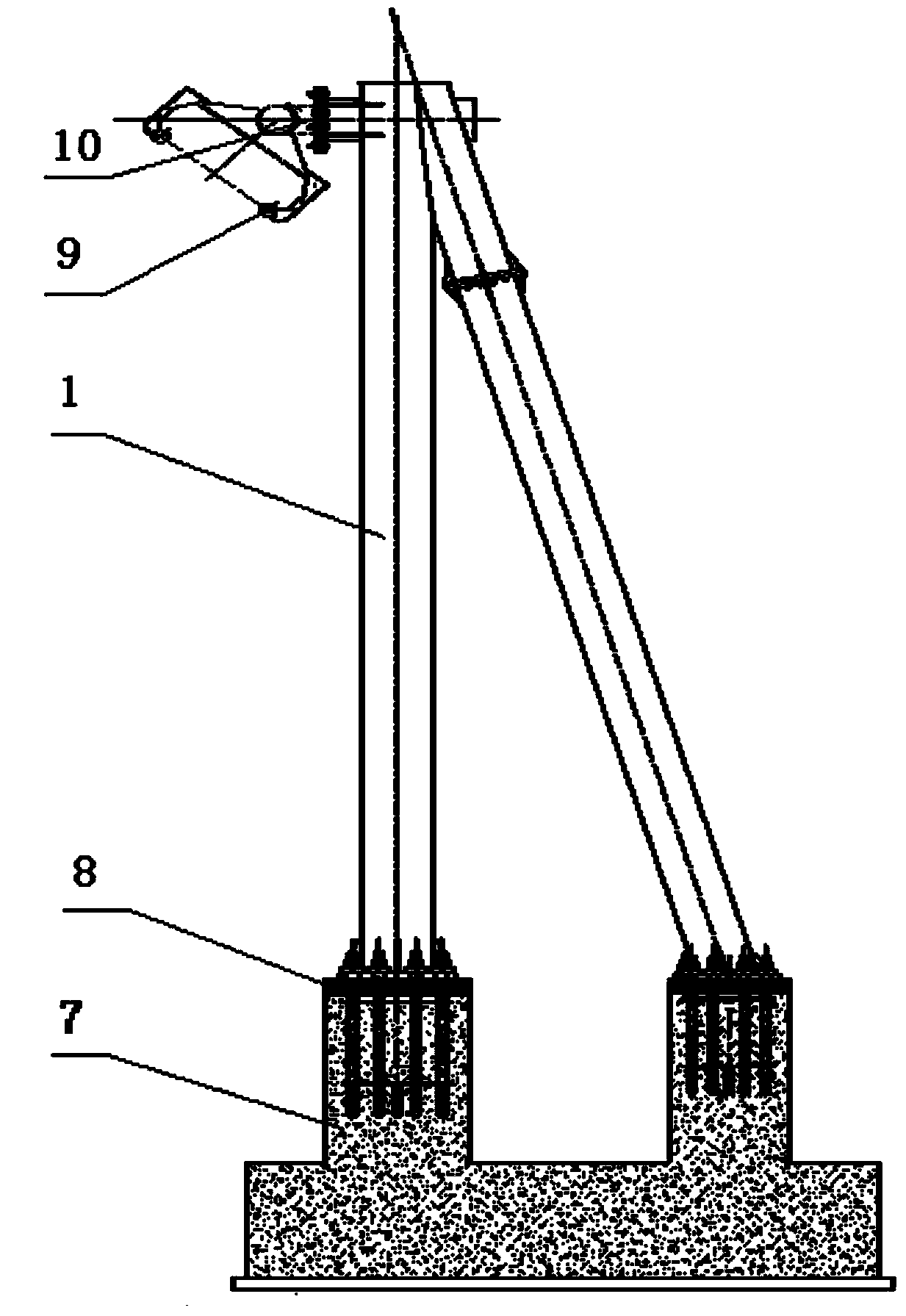

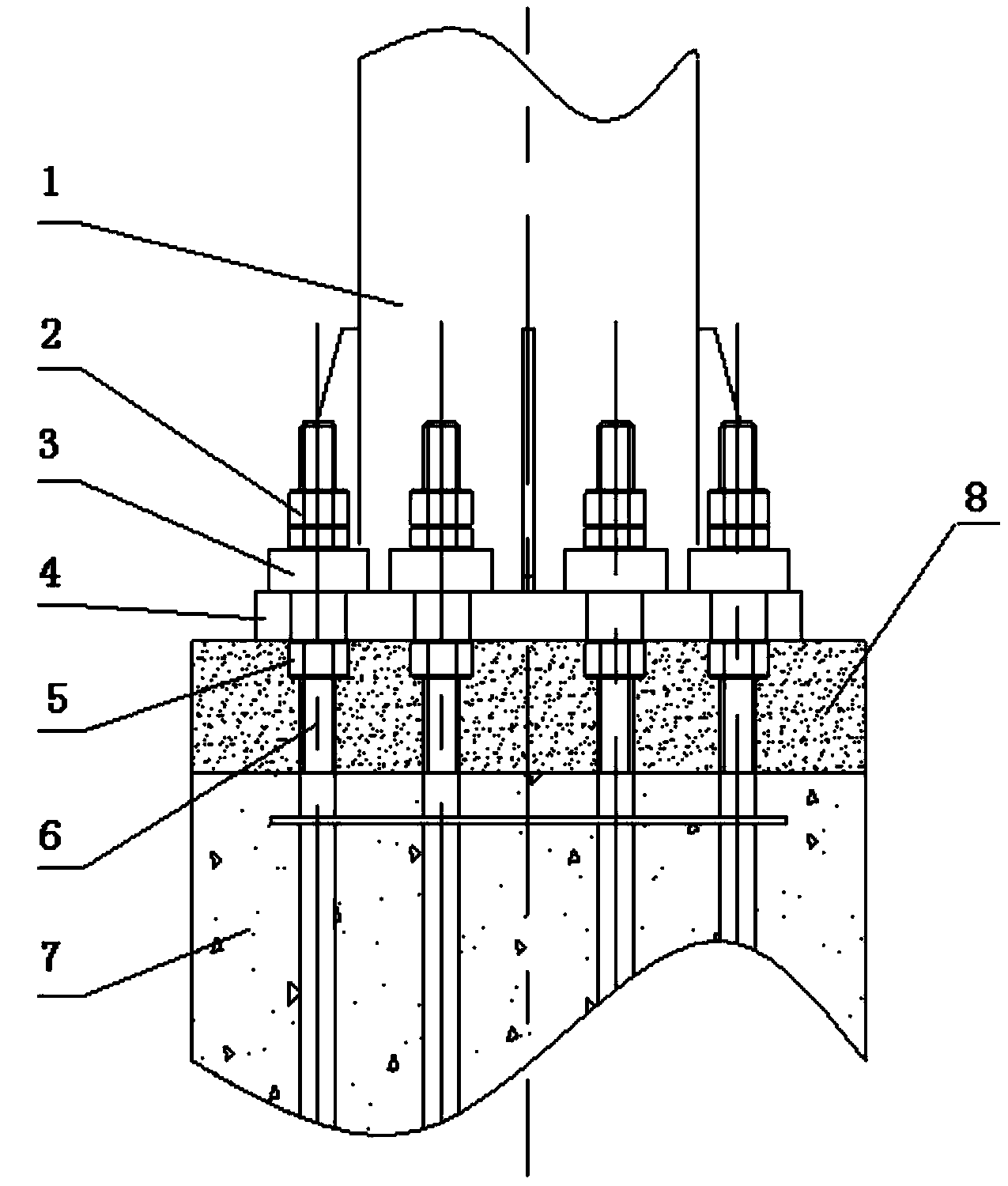

[0009] A roller coaster column structure and installation method according to the embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings: figure 1 And attached figure 2 A roller coaster column structure is disclosed in figure 1 For the column installation diagram, figure 2 It is the installation structure diagram of the column foot; the column structure of the roller coaster mainly includes the column 1, the anchor nut 2, the spacer 3, the column foot plate 4, the adjusting nut 5, the anchor bolt 6, the foundation 7, the secondary grouting layer 8, the track 9, the connection Point 10; each anchor bolt 6 is fitted with an adjusting nut 5 and spacer 3; the spacer 3 is located in the middle of the anchor nut 2 and the column foot plate 4; the secondary grouting layer 8 is located above the foundation 7 and on the column foot plate 4; the adjusting nut 5 sleeved on the anchor bolt 6 is located in the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com