Method for sepiolite/nano TiO2 in situ synthesis and doping modification

An in-situ synthesis, sepiolite technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low purification rate and poor additive effect, and achieve strong oxidation ability, Good formaldehyde removal ability, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

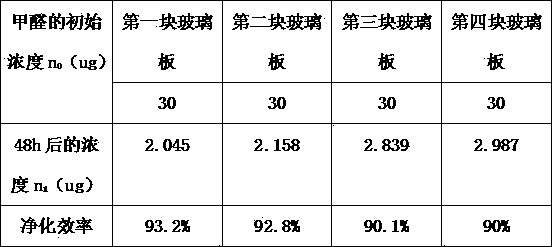

Examples

Embodiment 1

[0026] A kind of sepiolite / nano-TiO 2 The method of in-situ synthesis, doping modification, sepiolite, tetrabutyl titanate and Gd 2 o 3 As raw materials, sepiolite / nano-TiO were synthesized by in-situ polymerization 2 Composite materials, including the following steps:

[0027] (1) Add 5g of sepiolite to a 250ml three-neck flask, slowly add 100ml of ethanol, 12.5ml of tetrabutyl titanate, stir at a speed of 400r / min for 30min in a constant temperature water bath at 25°C, and then ultrasonically disperse for 30min to make the seafoam The stone and the solution are mixed evenly;

[0028] (2) Add 0.1g Gd 2 o 3 Dissolve in 1.5ml dilute hydrochloric acid and add to the three-necked bottle;

[0029] (3) Heat up to 90°C and stir the solution at a speed of 500r / min until the ethanol is completely volatilized, add 187.5ml of water, and heat until the water is completely volatilized;

[0030] (4) Wash the product several times with water, put it in a vacuum drying oven at 60°C fo...

Embodiment 2

[0033] A kind of sepiolite / nano-TiO 2 The method of in-situ synthesis, doping modification, sepiolite, tetrabutyl titanate and Gd 2 o 3 As raw materials, sepiolite / nano-TiO were synthesized by in-situ polymerization 2 Composite materials, including the following steps:

[0034] (1) Add 8g of sepiolite to a 250ml three-necked flask, slowly add 130ml of ethanol, 20ml of tetrabutyl titanate, stir at a speed of 600r / min in a constant temperature water bath at 40°C for 22min, and then ultrasonically disperse for 35min to make the sepiolite and The solution is mixed evenly;

[0035] (2) Add 0.2g Gd 2 o 3 Dissolve in 3ml dilute hydrochloric acid and add to the three-necked bottle;

[0036] (3) Heat up to 80°C and stir the solution at a speed of 600r / min until the ethanol is completely volatilized, add 200ml of water, and heat until the water is completely volatilized;

[0037] (4) Wash the product several times with water, put it in a vacuum drying oven at 75°C for 10h, and pu...

Embodiment 3

[0039] A kind of sepiolite / nano-TiO 2 The method of in-situ synthesis, doping modification, sepiolite, tetrabutyl titanate and Eu 2 o 3 As raw materials, sepiolite / nano-TiO were synthesized by in-situ polymerization 2 Composite materials, including the following steps:

[0040] (1) Add 5g of sepiolite to a 250ml three-necked bottle, slowly add 100ml of ethanol, 12.5ml of tetrabutyl titanate, stir at a speed of 400r / min for 30min in a constant temperature water bath at 25°C, and then ultrasonically disperse for 30min to make the seafoam The stone and the solution are mixed evenly;

[0041] (2) Add 0.1g Eu 2 o 3 Dissolve in 1.5ml dilute hydrochloric acid and add to the three-necked bottle;

[0042] (3) Heat up to 90°C and stir the solution at a speed of 500r / min until the ethanol is completely volatilized, add 187.5ml of water, and heat until the water is completely volatilized;

[0043](4) Wash the product several times with water, put it in a vacuum drying oven at 60°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com