Automatic blanking die of sheet metal part

An automatic punching and sheet metal parts technology, applied in the field of sheet metal parts processing equipment, can solve the problems of inability to achieve high-quality, high-efficiency punching, insufficient output force of the cylinder, and low quality of sheet metal parts, so as to avoid output force Insufficient, increased service life, high-efficiency blanking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

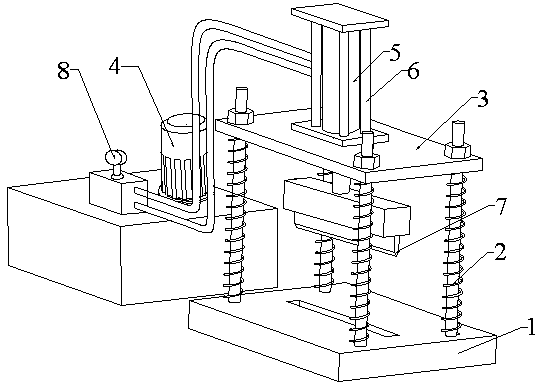

[0023] In addition, the upper and lower surfaces of the hydraulic cylinder 5 are provided with mounting plates, and four support rods 6 are evenly distributed between the upper and lower mounting plates. The taper angle of the tapered portion of the lower end face of the punch 7 is 60°. The material of the tapered portion of the lower end face of the punch 7 is 45# steel.

[0024] In use, the motor 4 controls the movement of the guide rod in the hydraulic cylinder 5, thereby driving the punch 7 connected to the guide rod to move up and down, and the operation of the motor is controlled by observing the oil pressure gauge 8 to ensure that the hydraulic cylinder 5 can be reliable. Stable operation, so as to realize the stable punching of the punch 7; in addition, because the end face of the punch 7 is provided with a taper angle, the contact area between the punching part and the sheet metal part is reduced, and fast and high-quality punching can be realized.

[0025] Example 2...

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com