Method for improving titanium alloy swaging forged structure homogeneity

A technology of uniform structure and titanium alloy, applied in the field of material processing, can solve the problems of insufficient broken as-cast structure, uneven structure of finished forgings, uneven deformation of crosses, etc., to improve the degree of process stability, good structure uniformity, Evenly organized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1. Upsetting deformation: Upsetting deformation is carried out along the axial direction of the ingot, and the deformation amount is about 30%. After the upsetting deformation, the material size is Φ380mm×400mm, and a drum shape appears on the side;

[0032] Step 2. Elongation deformation: Overturn the ingot deformed by upsetting in step 1 at 90°, compress it by about 20% in the axial direction, turn it over 90°, continue to compress it by about 20%, turn it over 90° again, and compress it by about 20% %, so repeatedly commutated to a titanium alloy with a square cross-section with a size of 250mm×250mm×670mm.

[0033] The H / D (height-to-diameter ratio) of the titanium alloy with a square cross section prepared in this example is ≤3. At this time, the upsetting deformation can be continued according to the actual needs, and the elongation deformation can also be continued until the finished forging.

Embodiment 2

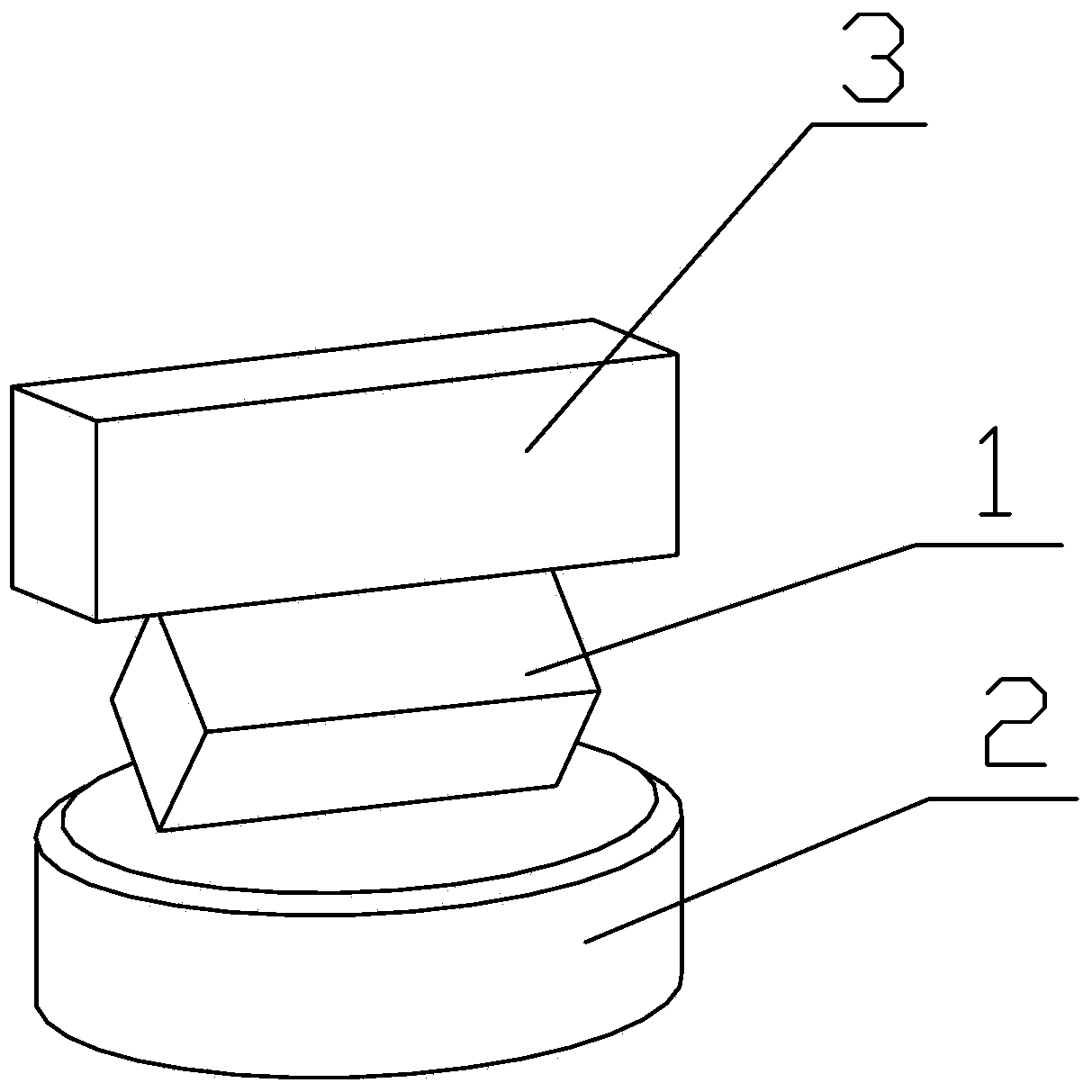

[0036] Step 1, such as figure 1 As shown, the titanium alloy 1 with a square cross section obtained in Example 1 is placed on the operating platform 2, so that the length direction of the titanium alloy 1 with a square cross section is parallel to the axial direction of the upper flat anvil 3, and along the four The diagonal direction of the square cross-section is overall flattening the titanium alloy 1 with a square cross-section to obtain a titanium alloy with a hexagonal cross-section; the reduction of the overall flattening is 30%;

[0037] Step 2, turning the titanium alloy with a hexagonal cross-section described in step 1 by 90° and then performing overall flattening to obtain a titanium alloy with an octagonal cross-section; the reduction of the overall flattening is 30%;

[0038] Step 3. Repeat step 2 for the titanium alloy having an octagonal cross-section described in step 2 until a titanium alloy forging with a square cross-section and a size of 250mm×250mm×670mm ...

Embodiment 3

[0041] Step 1, such as figure 1 As shown, the titanium alloy 1 with a square cross section obtained in Example 1 is placed on the operating platform 2, so that the length direction of the titanium alloy 1 with a square cross section is parallel to the axial direction of the upper flat anvil 3, and along the four The diagonal direction of the square section will have the titanium alloy 1 with a square section to be overall flattened to obtain a titanium alloy with a hexagonal section; the reduction of the overall flattening is 40%;

[0042] Step 2, turning over the titanium alloy with a hexagonal cross-section described in step 1 by 90° and then performing overall flattening to obtain a titanium alloy with an octagonal cross-section; the reduction of the overall flattening is 40%;

[0043] Step 3. Repeat step 2 for the titanium alloy having an octagonal cross-section described in step 2 until a titanium alloy forging with a square cross-section and a size of 250mm×250mm×670mm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com