Method for preventing wire cutting steel wires from being broken and improving silicon wafer yield

A technology for cutting steel wire and silicon rod yield rate, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc. Line defects, preventing splits, and ensuring the effect of chip yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

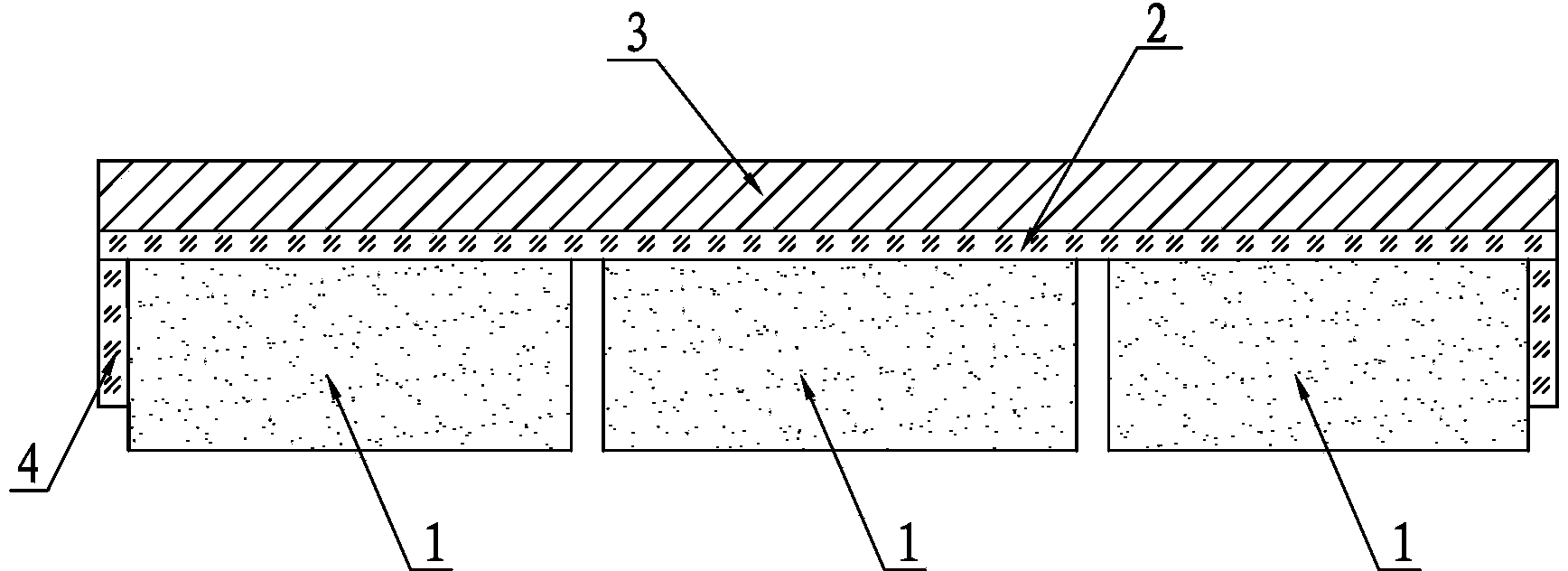

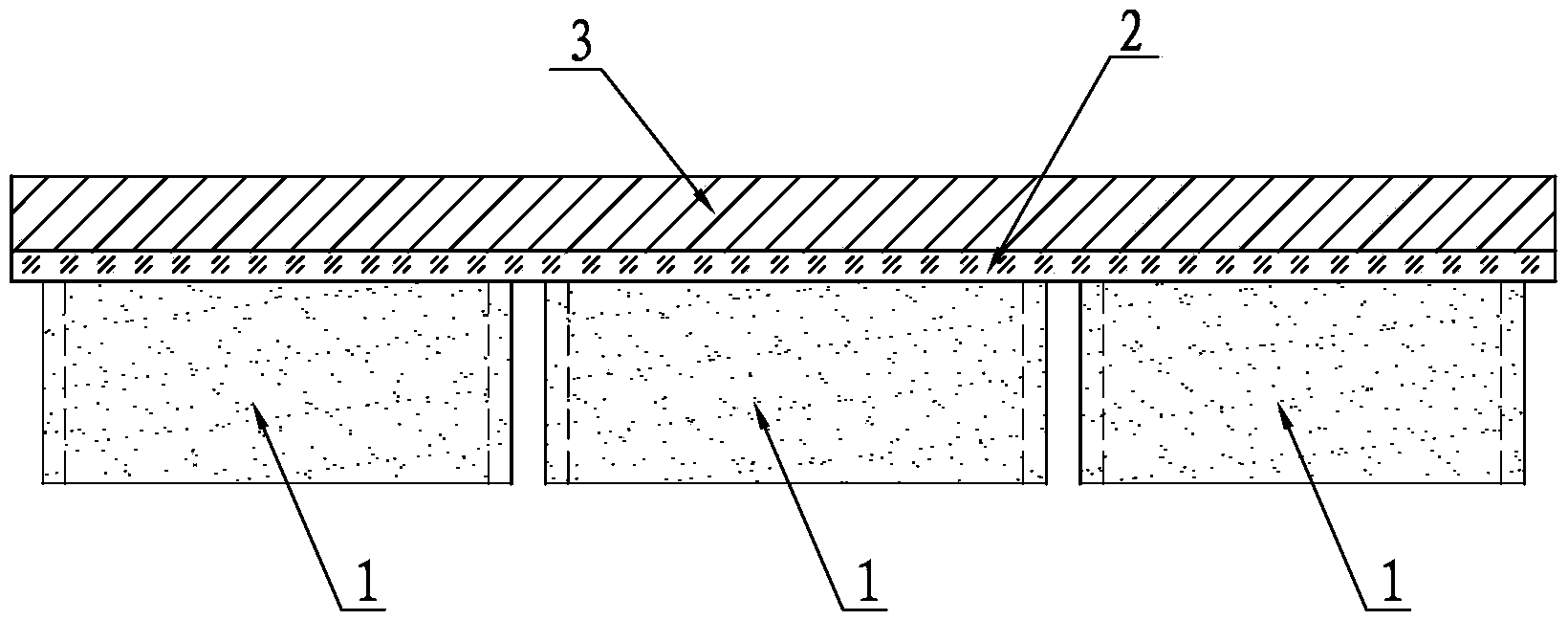

[0017] Embodiment 1: a kind of method that prevents the cutting steel wire from breaking and improves the yield of silicon rods,

[0018] The first step, cutting of square sub-ingots: cutting the polysilicon ingots into square sub-ingots;

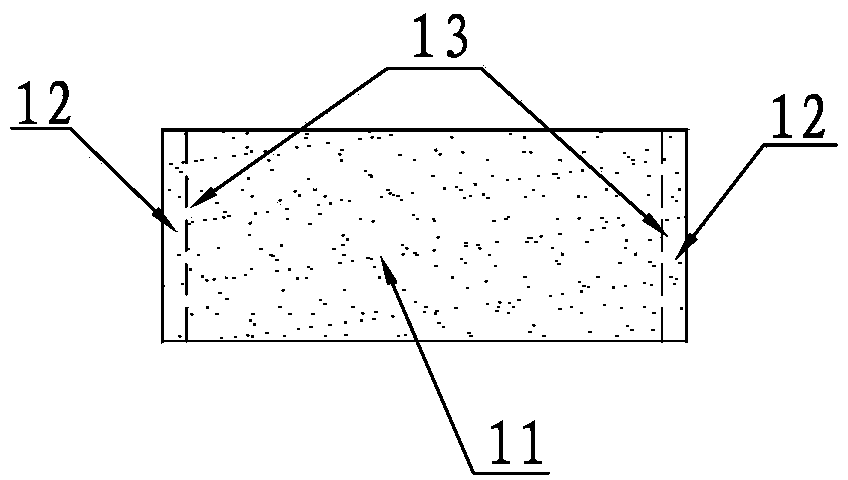

[0019] The second step is to cut the silicon ingot to be sliced: the square sub-ingot obtained in the first step is subjected to the minority carrier lifetime test, and the silicon wafer cutting section 11 and the silicon wafers located at both ends of the silicon wafer cutting section are determined according to the minority carrier lifetime parameter. Invalid section of the rod, and marking line 13 is marked at the boundary. When cutting off the invalid section of the silicon rod at both ends, a process protection section 12 of 2 to 5 mm is reserved at both ends of the silicon wafer cutting section 11. After cutting Obtain the sub-ingot silicon rod 1 with the process protection end, the sub-ingot silicon rod 1 with the process protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com