3C-SiC epitaxial structure

An epitaxial structure, 3c-sic technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of poor bonding force between the film and the substrate, poor adhesion, unfavorable 3C-SiC nucleation and growth, etc., to achieve inhibition Interfacial void defects, improving the withstand voltage performance, and alleviating the effects of lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

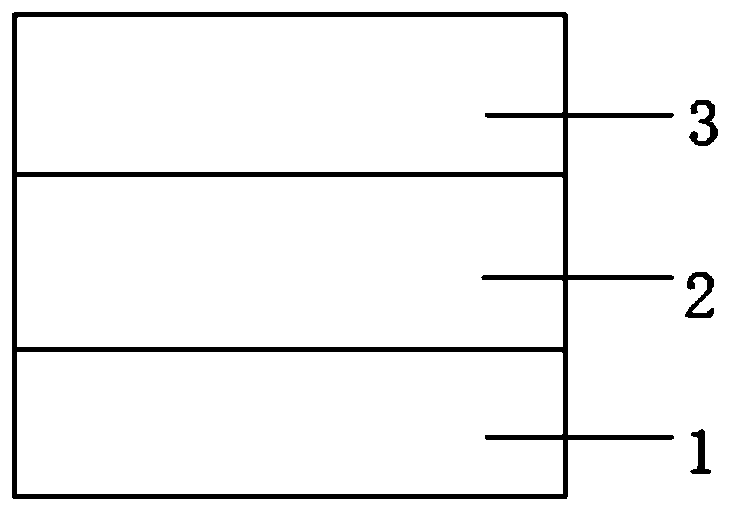

[0041] A 3C-SiC epitaxial structure, the 3C-SiC epitaxial structure includes a substrate 1, a GaN buffer layer 2, and a 3C-SiC epitaxial layer 3 sequentially from bottom to top.

[0042] The preparation method of the 3C-SiC epitaxial structure comprises the following steps:

[0043] 1) Putting the substrate into the reaction chamber of the CVD system, and evacuating the reaction chamber; the substrate is a sapphire substrate;

[0044] 2) Growth of GaN buffer layer: Carrier gas H is introduced at flow rates of 10-50slm, 50-100sccm and 80-200sccm respectively 2 , TMGa and NH 3 , growing a GaN layer with a thickness of 10-500nm at a temperature of 1000-1250°C and a pressure of 100-500mbar;

[0045] 3) Growth of 3C-SiC epitaxial layer: Introduce H at flow rates of 10-50slm, 100-500sccm, 100-500sccm, 80-150sccm and 15-50sccm respectively 2 , silicon source, carbon source and N 2 , growing an epitaxial layer with a thickness of 10-100 μm at a temperature of 1200-1450 ° C and a pre...

Embodiment 2

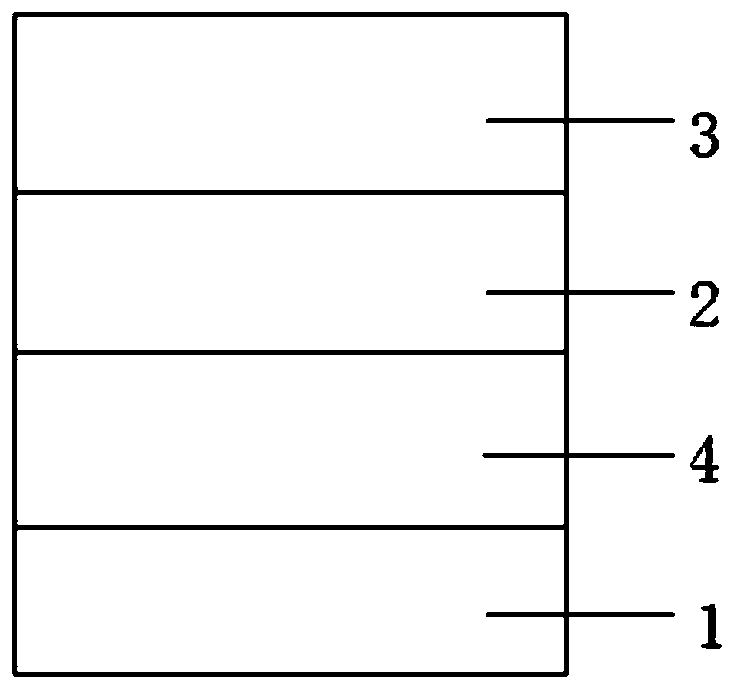

[0048] A 3C-SiC epitaxial structure, the 3C-SiC epitaxial structure sequentially includes a substrate, an AlGaN buffer layer 4, a GaN buffer layer 2, and a 3C-SiC epitaxial layer 3 from bottom to top.

[0049] The preparation method of the 3C-SiC epitaxial structure comprises the following steps:

[0050] 1) Putting the substrate into the reaction chamber of the CVD system, and evacuating the reaction chamber; the substrate is a sapphire substrate;

[0051] 2) Growth of AlGaN buffer layer: the carrier gas H is passed through at the flow rates of 10-50slm, 50-100sccm, 50-100sccm and 80-200sccm respectively 2 , TMGa, TMAl and NH 3 , growing an AlGaN layer with a thickness of 10-500nm and an Al composition of 10-40% at a temperature of 1000-1250°C and a pressure of 100-500mbar;

[0052] 3) Growth of GaN buffer layer: Carrier gas H is introduced at flow rates of 10-50slm, 50-100sccm and 80-200sccm respectively 2 , TMGa and NH 3 , growing a GaN layer with a thickness of 10-500n...

Embodiment 3

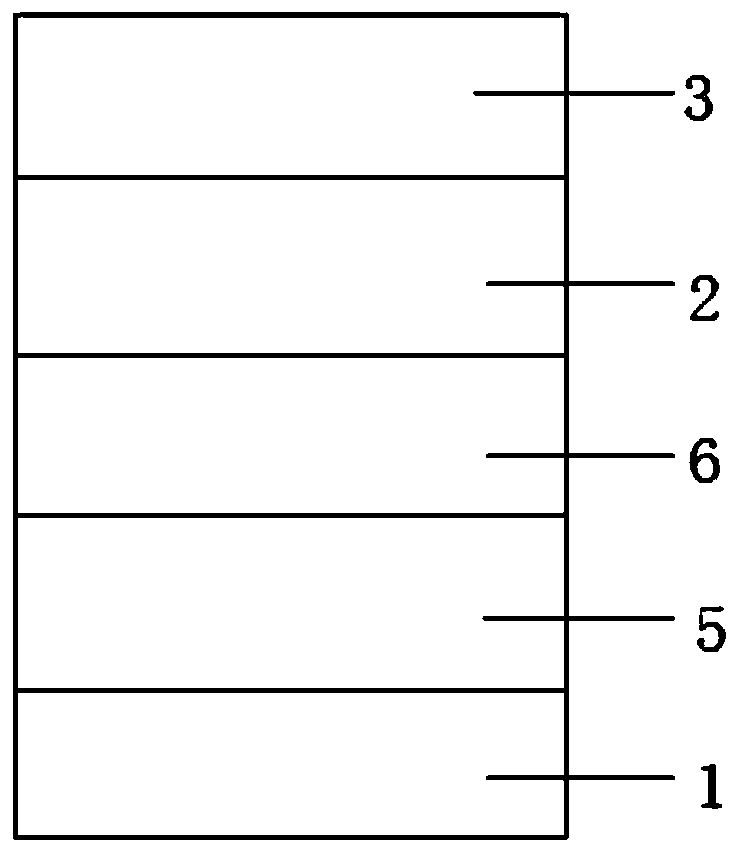

[0056] A 3C-SiC epitaxial structure, the 3C-SiC epitaxial structure sequentially includes a substrate 1, an AlGaN buffer layer A5, an AlGaN buffer layer B6, a GaN buffer layer 2, and a 3C-SiC epitaxial layer 3 from bottom to top.

[0057] The preparation method of the 3C-SiC epitaxial structure comprises the following steps:

[0058] 1) Put the substrate into the reaction chamber of the CVD system, and evacuate the reaction chamber; the substrate is a sapphire substrate;

[0059] 2) Growth of AlGaN buffer layer A: Pass carrier gas H at flow rates of 10-50slm, 50-100sccm, 50-100sccm and 80-200sccm respectively 2 , TMGa, TMAl and NH 3 , growing an AlGaN layer with a thickness of 10-500nm and an Al composition of 30-40% at a temperature of 1000-1250°C and a pressure of 100-500mbar;

[0060] 3) Growth of the AlGaN buffer layer B: flow the carrier gas H at the flow rates of 10-50slm, 50-100sccm, 50-100sccm and 80-200sccm respectively 2 , TMGa, TMAl and NH 3 , growing an AlGaN l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com