Oil and gas well exploiting sewage efficient cavitation processing device and method

A high-efficiency technology for mining sewage, applied in chemical instruments and methods, energy wastewater treatment, water/sewage treatment, etc., can solve the problems of no better treatment method, easy blockage and saturation of activated carbon, and little removal effect, etc., to achieve structural Simple, convenient management, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

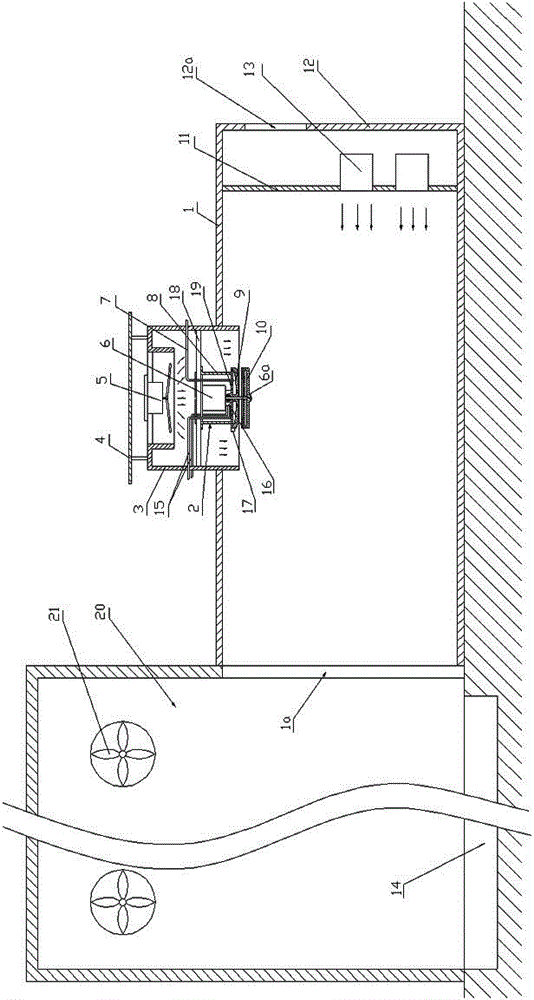

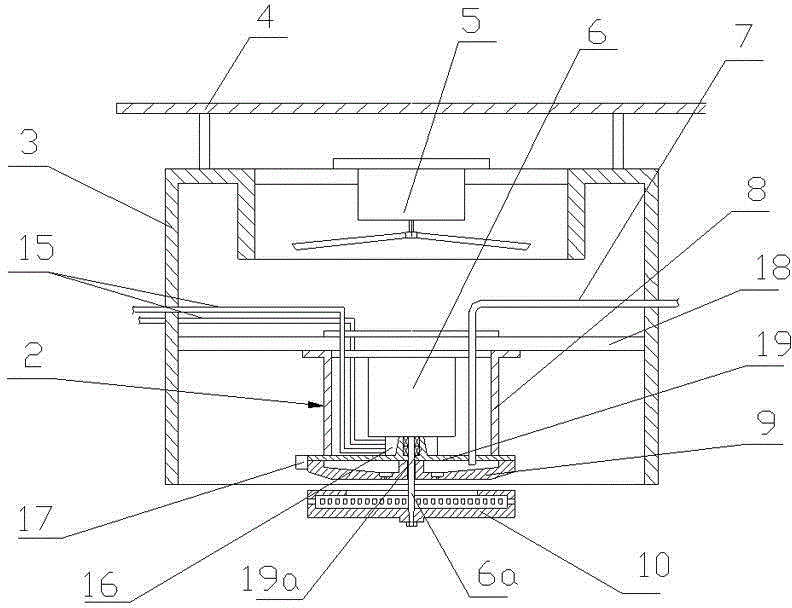

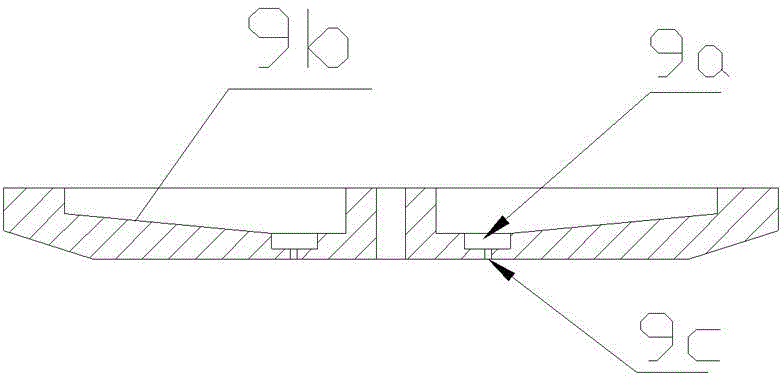

[0053] see Figure 1 to Figure 4 , an embodiment of oil and natural gas drilling and mining sewage treatment equipment, including a cavitation chamber 1, a settling chamber 20, an atomization reaction 2, and a fan. The cavitation chamber 1 and the settling chamber 20 are made of metal plates, and may also be made of concrete poured civil engineering. The depth length of the cavitation chamber 1 is greater than the width, and the depth length of the cavitation chamber 1 is 3-10m, the width is 2-5m, and the height is 2-8m. good. The volume of the settling chamber 20 is larger than that of the cavitation chamber 1, and it is advisable that the inner space of the settling chamber 20 is 2 times or more than the inner space of the cavitation chamber 2. The larger the settling chamber, the better the effect of sedimentation and separation. One end of the cavitation chamber 1 along the depth direction is the first air inlet end, the outer end wall 12 of the first air inlet end is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com