Compound Asphalt Emulsifier Containing Gemini Surfactant

A technology of surfactant and asphalt emulsifier, which is applied in building components, building insulation materials, construction, etc., can solve the problems of large amount of surfactant, too much emulsifier, and increased production cost of asphalt emulsion. Good, overcoming the effect of large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

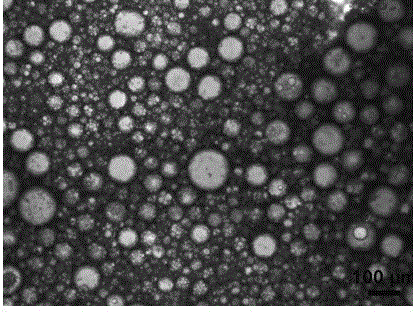

Image

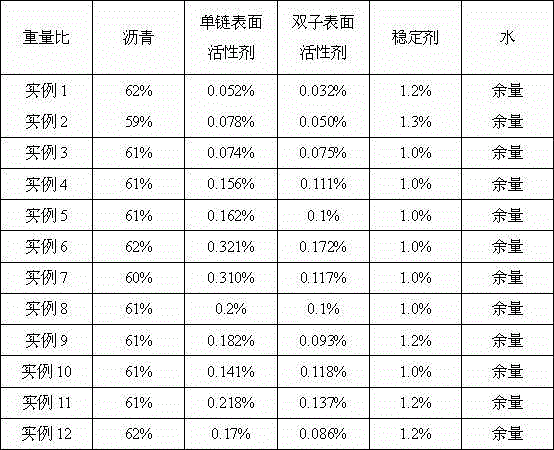

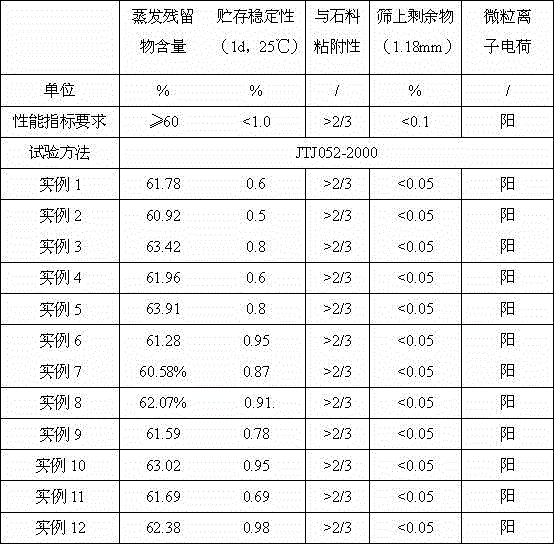

Examples

Embodiment 1

[0028] Weigh 35.6g of asphalt, and keep the temperature in an oven at 150±0.5°C for 60 minutes; weigh 0.0300 of octadecyltrimethylammonium chloride, 0.0182g, add 14ml of deionized water to dissolve, after the emulsion is completely dissolved, put it in a water bath at 65°C for 20 minutes; weigh 0.696g of NaCl, add 8ml of deionized water to dissolve, put it in a water bath at 65°C Keep the temperature constant for 20 minutes; after the asphalt and emulsion are kept at constant temperature, disperse on a high-shear dispersing emulsifier at a speed of 16,000 rpm for 5 minutes, and finally add the NaCl solution to the asphalt emulsion, which is the final asphalt emulsion.

Embodiment 2

[0030] Weigh 32g of asphalt and keep the temperature in an oven at 150±0.5°C for 60 minutes; weigh 0.0422g of octadecyltrimethylammonium chloride, ethane-1,2-dioctadecyldimethylammonium chloride 0.0268g, add 14ml of deionized water to dissolve, after the emulsion is completely dissolved, put it in a water bath at 65°C for 20 minutes; weigh 0.696g of NaCl, add 8ml of deionized water to dissolve, put it in a water bath at 65°C Keep the temperature constant for 20 minutes; after the asphalt and emulsion are kept at constant temperature, disperse on a high-shear dispersing emulsifier at a speed of 16,000 rpm for 5 minutes, and finally add the NaCl solution to the asphalt emulsion, which is the final asphalt emulsion.

Embodiment 3

[0032]Weigh 35g of asphalt, and keep the temperature in an oven at 150±0.5°C for 60 minutes; weigh 0.0420g of octadecyltrimethylammonium chloride, ethane-1,2-dioctadecyldimethylammonium chloride 0.0428g, add 14ml of deionized water to dissolve, after the emulsion is completely dissolved, put it in a water bath at 65°C for 20 minutes; weigh 0.5568g of NaCl, add 8ml of deionized water to dissolve, put it in a water bath at 65°C Keep the temperature constant for 20 minutes; after the asphalt and emulsion are kept at constant temperature, disperse on a high-shear dispersing emulsifier at a speed of 16,000 rpm for 5 minutes, and finally add the NaCl solution to the asphalt emulsion, which is the final asphalt emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com