Composite floor paint, preparation method thereof and using method thereof

A floor coating and coating technology, applied in the field of floor coatings, can solve the problems of poor durability, easy pulverization, and easy yellowing, and achieve low volatile organic compound release, good anti-skid and wear resistance, and reduced hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

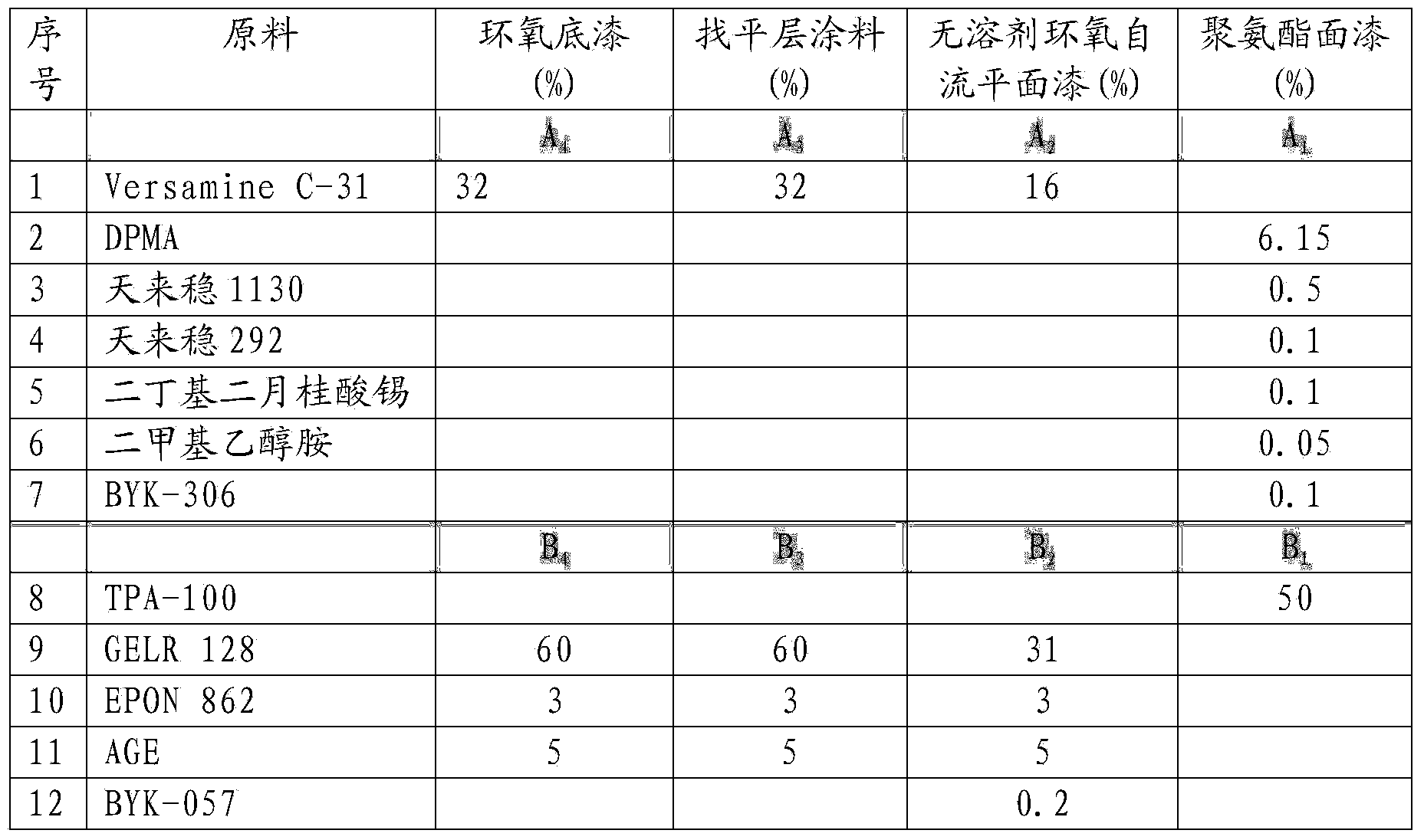

[0036] The raw material ratio of epoxy primer, leveling coat, solvent-free epoxy self-leveling paint and polyurethane topcoat is shown in Table 1.

[0037] The raw material ratio of each coating coating in the embodiment 1 of table 1

[0038]

[0039]

[0040] Preparation of epoxy primer: Mix low molecular weight bisphenol A liquid epoxy resin, low molecular weight bisphenol F type liquid epoxy resin and reactive diluent at a speed of 300-500r / min for 10-20min and mix evenly, filter and packed B 4 Components, the solvent-free modified alicyclic amine curing agent is packaged independently to get A 4 components. During construction, put A 4 Component and B 4 The components are mixed and stirred evenly to obtain a solvent-free epoxy primer.

[0041] Preparation of leveling layer coating: Mix low molecular weight bisphenol A type liquid epoxy resin, low molecular weight bisphenol F type liquid epoxy resin and reactive diluent at a speed of 300-500r / min for 10-20min and...

Embodiment 2

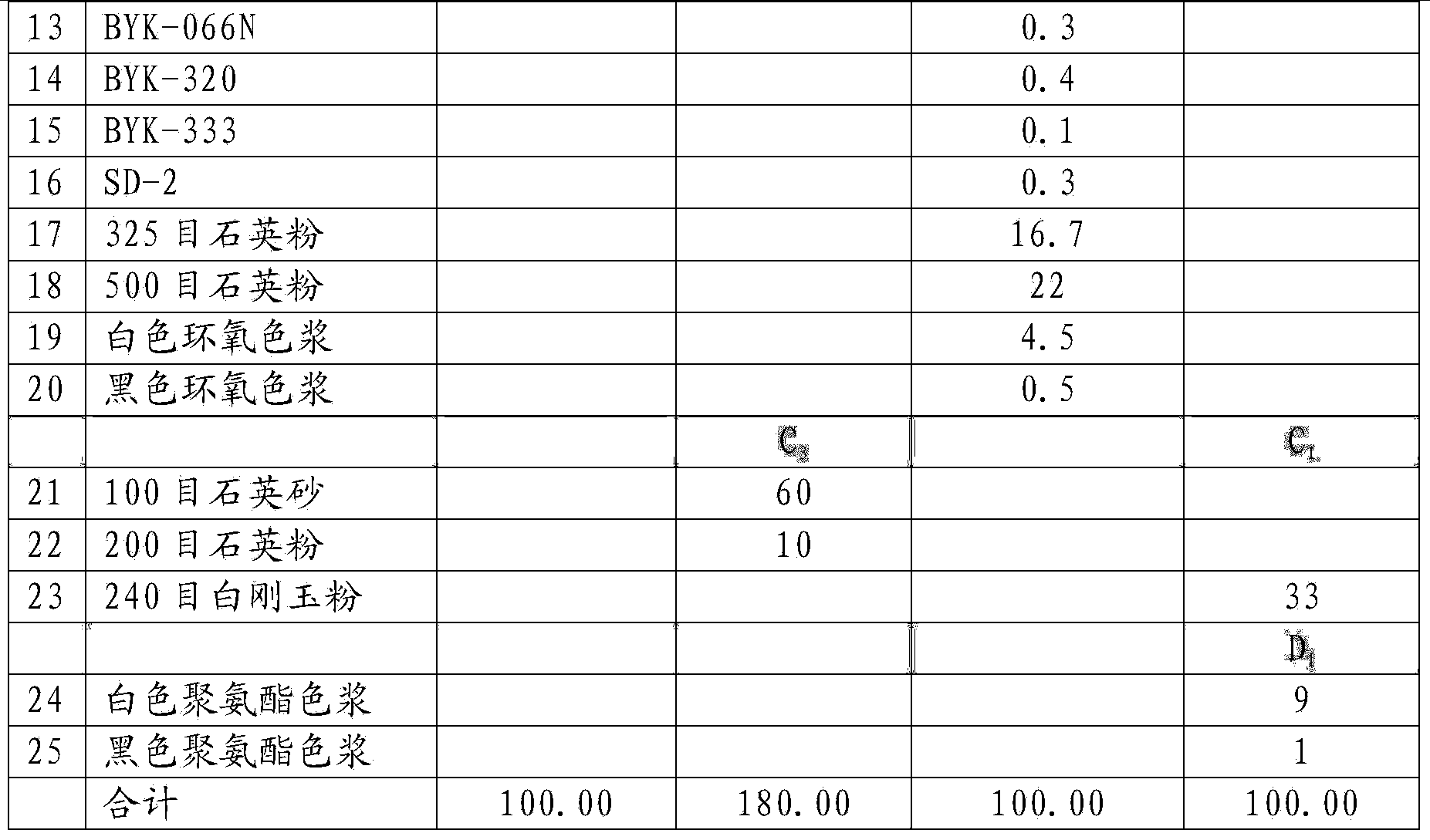

[0049] The ratio of raw materials for epoxy primer, leveling coat, solvent-free epoxy self-leveling paint and polyurethane topcoat is shown in Table 2.

[0050] The raw material ratio of each coating coating in table 2 embodiment 2

[0051]

[0052] The preparation methods of the epoxy primer, leveling coating, solvent-free epoxy self-leveling paint and polyurethane topcoat of this embodiment are the same as those described in Example 1.

[0053] The use method of the composite floor coating of this embodiment is basically the same as that described in Example 1, the difference is: the amount of leveling layer paint is 0.5kg / ㎡; the amount of solvent-free epoxy self-leveling paint is 1.5 kg / ㎡, the amount of polyurethane topcoat is 0.15kg / ㎡.

[0054] The performance of the composite floor composed of primer, leveling layer, solvent-free epoxy self-leveling paint layer and polyurethane topcoat layer is shown in Table 4.

Embodiment 3

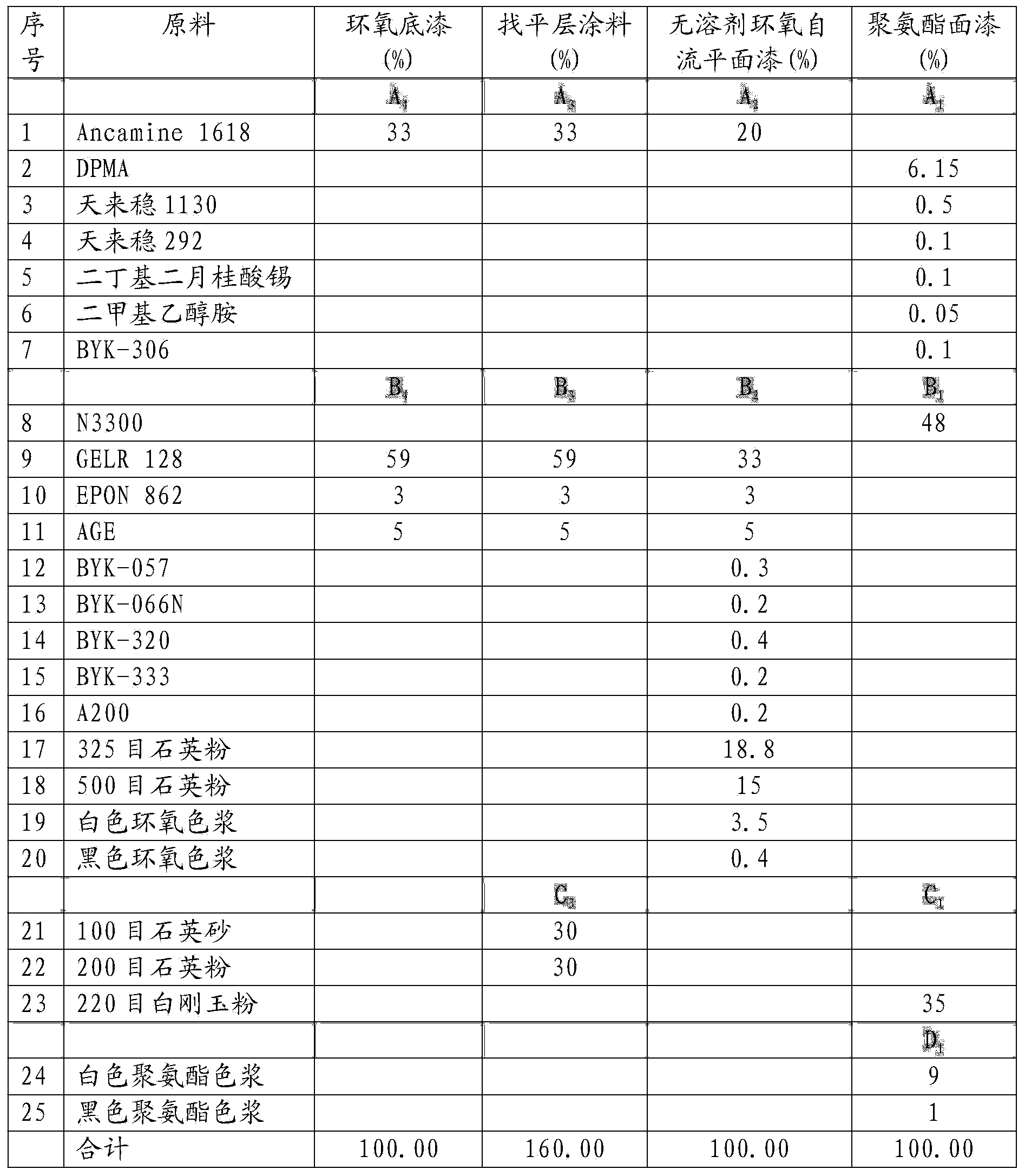

[0056] The raw material ratio of epoxy primer, leveling coat, solvent-free epoxy self-leveling paint and polyurethane topcoat is shown in Table 3.

[0057] The raw material ratio of each coating coating in table 3 embodiment 3

[0058]

[0059]

[0060] The preparation methods of the epoxy primer, leveling coating, solvent-free epoxy self-leveling paint and polyurethane topcoat of this embodiment are the same as those described in Example 1.

[0061] The use method of the composite floor coating of this embodiment is basically the same as that described in Example 1, the difference is: the amount of leveling layer paint is 0.3kg / ㎡; the amount of solvent-free epoxy self-leveling paint is 1.8 kg / ㎡, the amount of polyurethane topcoat is 0.13kg / ㎡.

[0062] The performance of the composite floor composed of primer, leveling layer, solvent-free epoxy self-leveling paint layer and polyurethane topcoat layer is shown in Table 4.

[0063] Table 4 The performance test data of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com