A kind of preparation technology of rubber interlayer TPU foam sole

A rubber interlayer and preparation technology, applied in footwear, other household appliances, household appliances, etc., can solve the problems of poor comfort, high specific gravity, poor elasticity, etc., achieve good vertical resilience, reduce weight, and improve wearing comfort sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

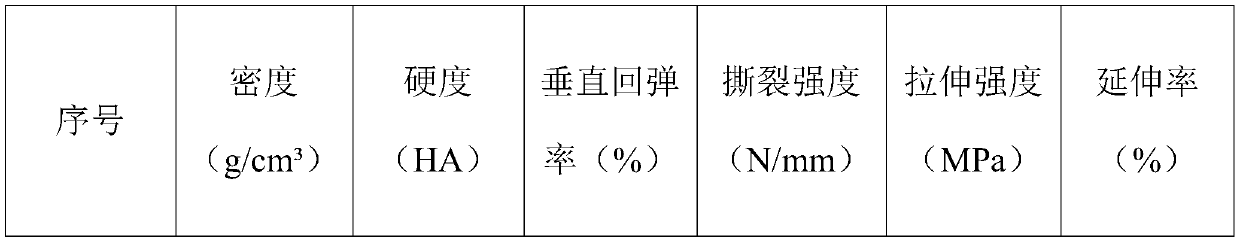

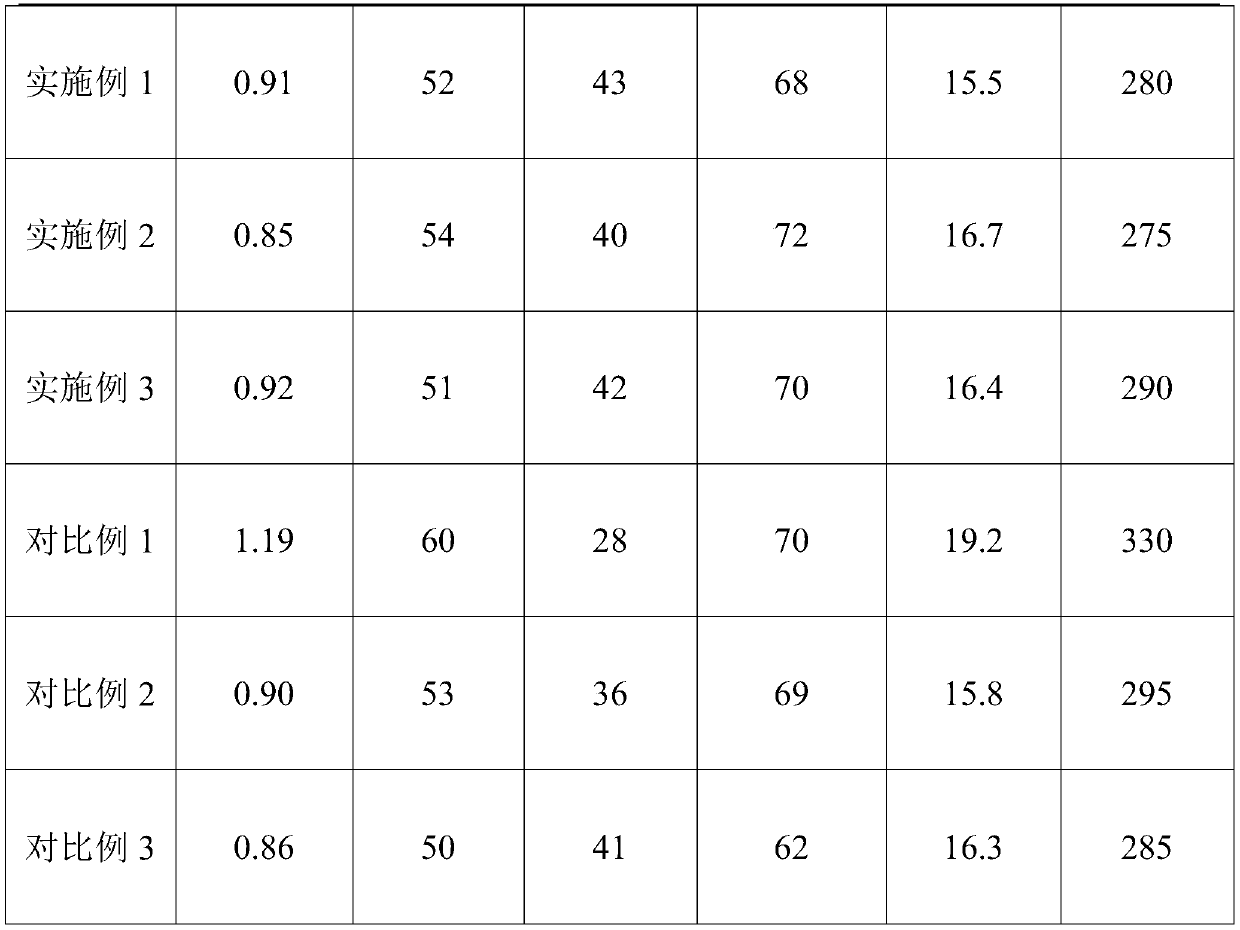

Examples

Embodiment 1

[0027] The preparation process of the rubber interlayer TPU foam sole of this embodiment includes the following steps:

[0028] S1. The granular TPU foam material is ultrasonically cleaned, and after the cleaning is completed, it is put into a vacuum drying oven to dry to obtain TPU foam particles; in this step, it is best to use a weak alkaline solution to ultrasonically clean the TPU foam material In this way, impurities and oil stains on the surface of the TPU foam material can be effectively removed, so that the TPU particles can better bond with the grounding bottom surface and the sole surface in the subsequent steps.

[0029] S2. Add 20 parts of natural rubber and 15 parts of styrene-butadiene rubber to the mixer, stir and mix evenly at 30°C, then add 3 parts of activator and 2 parts of carbon black, the activator is zinc oxide or zinc stearate, Mix for 10 minutes at a mixing temperature of 150°C, then put the evenly mixed rubber into an open mill for 3 minutes to obtain a 3...

Embodiment 2

[0036] The preparation process of the rubber interlayer TPU foam sole of this embodiment includes the following steps:

[0037] S1. The granular TPU foam material is ultrasonically cleaned, and after the cleaning is completed, it is put into a vacuum drying oven to dry to obtain TPU foam particles; in this step, it is best to use a weak alkaline solution to ultrasonically clean the TPU foam material In this way, impurities and oil stains on the surface of the TPU foam material can be effectively removed, so that the TPU particles can better bond with the grounding bottom surface and the sole surface in the subsequent steps.

[0038] S2. Add 25 parts of natural rubber and 20 parts of styrene-butadiene rubber to the mixer, stir and mix evenly at 40°C, and then add 4 parts of activator and 3 parts of carbon black. The activator is zinc oxide or zinc stearate. Mix for 12 minutes at a mixing temperature of 160°C, and then put the evenly mixed rubber into an open mill for 5 minutes to ob...

Embodiment 3

[0045] The preparation process of the rubber interlayer TPU foam sole of this embodiment includes the following steps:

[0046] S1. The granular TPU foam material is ultrasonically cleaned, and after the cleaning is completed, it is put into a vacuum drying oven to dry to obtain TPU foam particles; in this step, it is best to use a weak alkaline solution to ultrasonically clean the TPU foam material In this way, impurities and oil stains on the surface of the TPU foam material can be effectively removed, so that the TPU particles can better bond with the grounding bottom surface and the sole surface in the subsequent steps.

[0047] S2. Add 30 parts of natural rubber and 25 parts of styrene-butadiene rubber to the mixer, stir and mix evenly at 45°C, and then add 5 parts of activator and 4 parts of carbon black. The activator is zinc oxide or zinc stearate. Mix for 15 minutes at a mixing temperature of 180°C, then put the evenly mixed rubber into an open mixer for 8 minutes to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com