Carbonyl iron powder capable of enhancing magnetorheological effect and magnetorheological fluid prepared from carbonyl iron powder

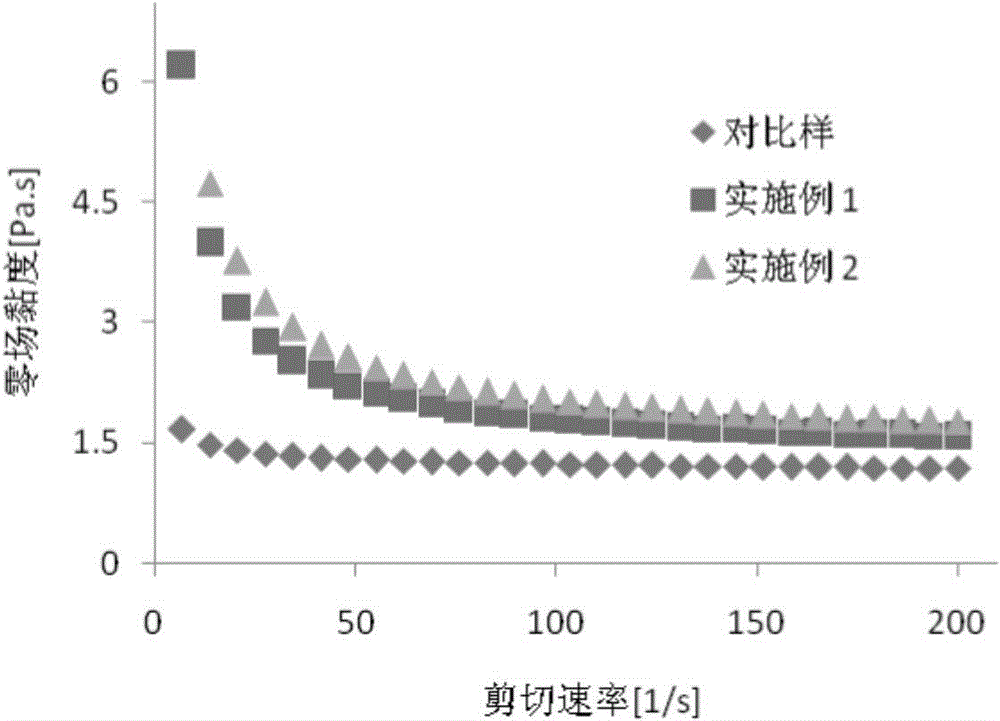

A technology of carbonyl iron powder and magnetorheological fluid, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of unfavorable popularization and application, high preparation cost, and inapplicability, and achieve improved settlement stability, low cost, Effect of Low Zero Field Viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare 100 ml (118.3 g) of silicone oil-based magnetorheological fluid, the preparation steps are:

[0041] Step 1. Dry 78.4g of carbonyl iron powder at a vacuum of 0.1MPa and a temperature of 70°C for 12 hours to remove physically adsorbed water on the surface;

[0042] Step 2. Add 1.2g of dimer acid to 35ml of isopropanol, stir evenly, dissolve and dilute to obtain a mixed solution;

[0043] Step 3. Add the dry carbonyl iron powder to the mixed solution obtained in step 2, stir evenly and then ultrasonically disperse for 20 minutes to obtain a suspension;

[0044] Step 4. Put the suspension obtained in step 3 into a ball mill tank, and then add zirconia balls with a diameter of 10 mm. The mass ratio of the mixture material to the balls is 1:3, and ball mill at a speed of 300 rpm for 6 to 8 hours. After grinding, the ball liquid is separated;

[0045] Step 5. Place the suspension obtained in step 4 in an electric vacuum drying oven, and dry it for 6 hours at a vacuu...

Embodiment 2

[0050] Prepare 100ml (118.3g) silicone oil-based magnetorheological fluid, the preparation steps are:

[0051] Step 1. Dry 78.4g of carbonyl iron powder at a vacuum of 0.1MPa and a temperature of 70°C for 12 hours to remove physically adsorbed water on the surface;

[0052] Step 2. Add 1.2g of dodecanedioic acid into 35ml of isopropanol, stir evenly, dissolve and dilute to obtain a mixed solution;

[0053] Step 3. Add the dry carbonyl iron powder to the mixed solution obtained in step 2, stir evenly and then ultrasonically disperse for 20 minutes to obtain a suspension;

[0054] Step 4. Put the suspension obtained in step 3 into a ball mill tank, and then add zirconia balls with a diameter of 10 mm. The mass ratio of the mixture material to the balls is 1:3, and ball mill at a speed of 300 rpm for 6 to 8 hours. After grinding, the ball liquid is separated;

[0055] Step 5. Put the suspension obtained in step 4 in an electric vacuum drying oven, and dry it for 6 hours at a vacu...

Embodiment 3

[0060] Prepare 100 milliliters (117.5g) of silicone oil-based magnetorheological fluid, the preparation steps are:

[0061] Step 1. Dry 78.4g of carbonyl iron powder at a vacuum of 0.1MPa and a temperature of 70°C for 12 hours to remove physically adsorbed water on the surface;

[0062] Step 2. Put 1.2g of dimer acid into 35ml of isopropanol, stir evenly, dissolve and dilute to obtain a mixed solution;

[0063] Step 3. Add the dry carbonyl iron powder to the mixed solution obtained in step 2, stir evenly and then ultrasonically disperse for 20 minutes to obtain a suspension;

[0064] Step 4. Put the suspension obtained in step 3 into a ball mill tank, and then add zirconia balls with a diameter of 10 mm. The mass ratio of the mixture material to the balls is 1:3, and ball mill at a speed of 300 rpm for 6 to 8 hours. After grinding, the ball liquid is separated;

[0065] Step 5. Put the suspension obtained in step 4 in an electric vacuum drying oven, and dry it for 6 hours at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com