Cleansing and cobalt-removing method for zinc smelting leachate and scavenging agent used therein

A leaching solution and zinc smelting technology, applied in the direction of improving process efficiency, etc., can solve the problems of low cobalt removal efficiency and difficult to guarantee impurity removal effect, and achieve no secondary pollution, favorable resource utilization, and high Co removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

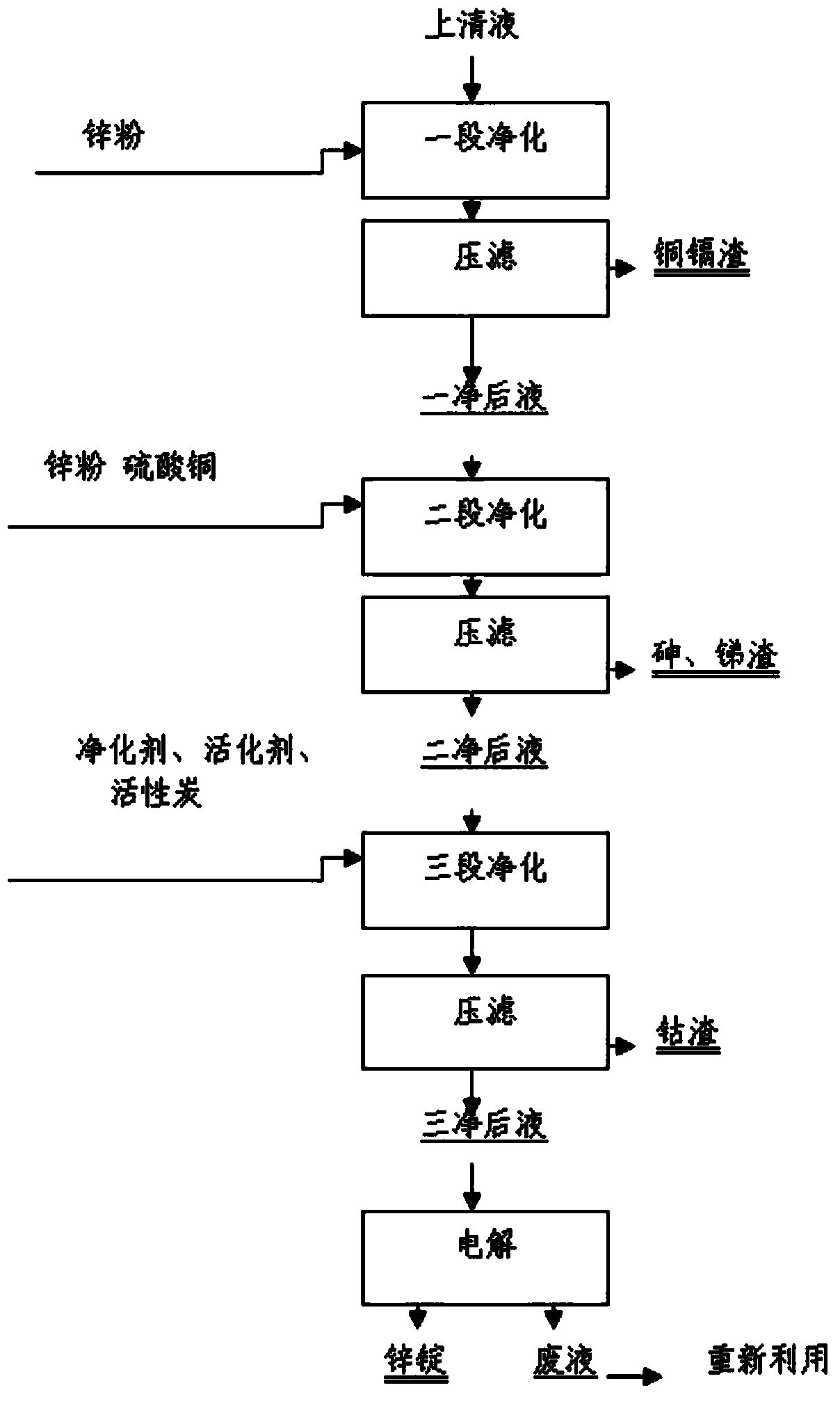

[0037] as attached figure 1 As shown, the process flow chart of an embodiment of the method for purifying and removing cobalt from the zinc smelting leachate of the present invention, the method for purifying and removing cobalt from the zinc smelting leachate described in this embodiment includes the following steps:

[0038] (1) One-stage purification: put the supernatant of the zinc smelting leaching solution in a clean tank, send samples to measure the content of Cu and Cd, control the temperature of the supernatant at 50-55°C, and follow the Cu+Cd content of 1-1.5 Double the calculated amount of zinc powder, slowly add 2 / 3 of the calculated amount of zinc powder, stir for 20 minutes, then add the remaining zinc powder, stir for 5 to 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com