Method for manufacturing stretch-cotton spandex super soft velvet fabric

A manufacturing method and technology of cotton spandex are applied in the field of textile fabrics to achieve the effects of reducing wool shearing, cleaning waste wool well, and solving varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

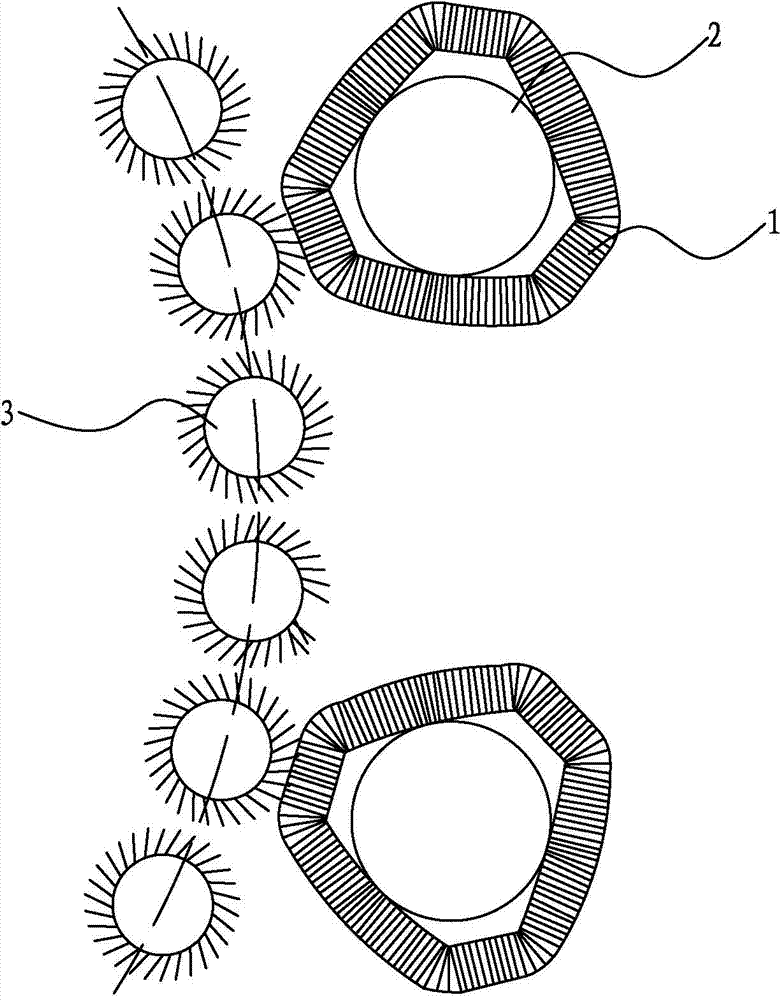

Image

Examples

Embodiment 1

[0018] The manufacturing method of the elastic cotton and spandex supersoft fleece fabric includes the steps of material selection and warping, weaving, presetting, shearing, secondary setting, dyeing and final setting.

[0019] The material selection warping step includes first yarn count warping, second yarn count warping, and third yarn count warping.

[0020] The first yarn count is 5.5tex bright white polyester yarn, the second yarn count is 5.5tex bright white polyester yarn, and the third yarn count is 4.4tex bright white spandex yarn.

[0021] The warping of the first yarn count adopts the GE218 warping machine, the yarn drafting speed is 700m / min, the drafting monofilament tension is 10-20g, the yarn feeding amount is 3030mm / rack, and the mass percentage is 64.7%; the second yarn count is After adopting GE218 warping machine, the yarn drafting speed is 700m / min, the drafting monofilament tension is 10-20g, the yarn feeding amount is 1300mm / rack, and the mass percentag...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap