Gasoline vaporizer

A carburetor and gasoline technology, applied in the direction of machines/engines, fuel heat treatment devices, mechanical equipment, etc., can solve the problems of low vaporization efficiency and inability to form a complete vaporization system, and achieve high vaporization efficiency, ease of use and debugging, and high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

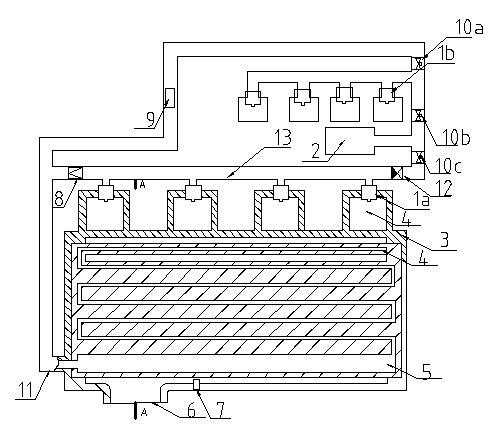

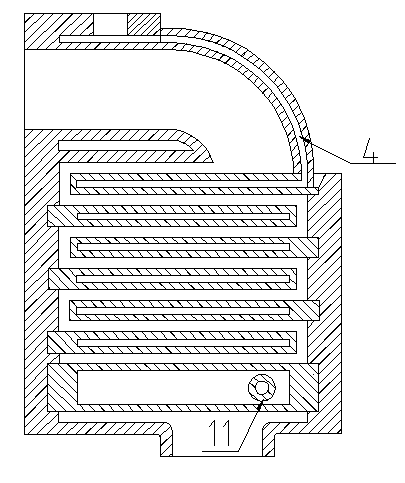

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] Engine exhaust hole 6 directly connects the present invention, by Figure 1~2 As shown, a kind of gasoline carburetor, its main structure is: gasoline pump 2 is connected with three-way, wherein one end of the three-way output port is connected to the electronically controlled fuel injector 1a through solenoid valve 10b and check valve 12, and the other end is connected through solenoid valve 10b is connected to the original fuel supply oil circuit of the automobile; a gasification chamber 4 is arranged under the fuel injection nozzle 1a, and the gasification chamber 4 is connected to the gas storage chamber 5; the outlet of the gas storage chamber 5 is connected to the gas pipeline 11, and the gas pipeline 11 is connected to After the connection, the output end of one end of the tee is connected to the original fuel supply oil circuit of the automobile through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com