Simulation test method for heat and humidity exchange of heading tunnel in deep mining of metal mine

A simulation test, deep mining technology, applied in wet exchange simulation test, deep mining heat field, can solve the problem that the parameters are difficult to meet the actual application, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

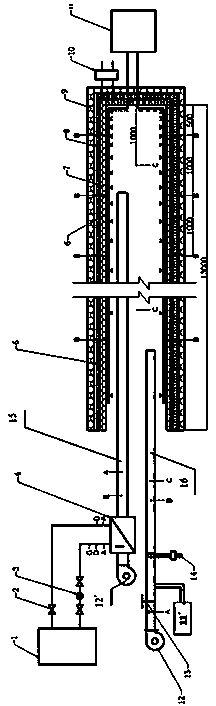

[0038] In order to describe the present invention, a simulation test method for heat and moisture exchange in a deep mining tunnel of a metal mine according to the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

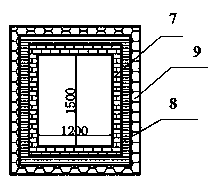

[0039] Depend on figure 1 As shown in the present invention, a special simulation test platform assembly diagram used in a metal mine deep mining roadway heat and moisture exchange simulation test method and combined figure 2It can be seen that the special-purpose simulation test platform adopted by the heat-moisture exchange simulation test method of a metal mine deep mining roadway of the present invention is composed of a simulated roadway, a roadway heat source simulation device, a humidity environment simulation device in the roadway, and a fresh air quality simulation device in the roadway. , roadway cooling simulation device and wind flow parameter measurement and control components. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com