Mutual capacitance type touch screen

A mutual capacitance and touch screen technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of difficult capacitive touch screen, electrode disconnection, interface separation, etc., to widen the conductor touch area , Reduce RC loading and ensure the effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

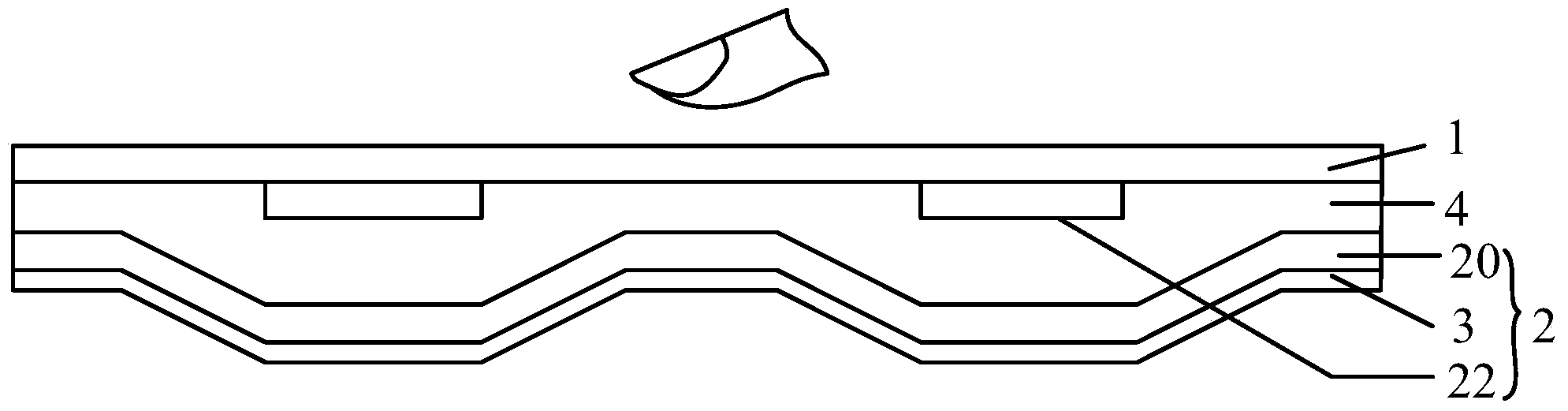

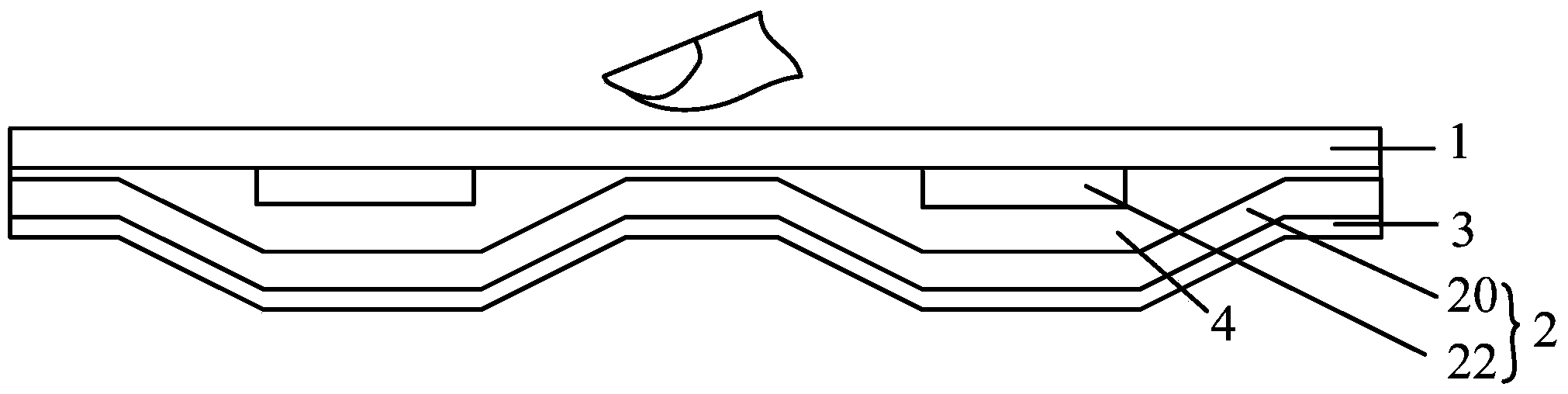

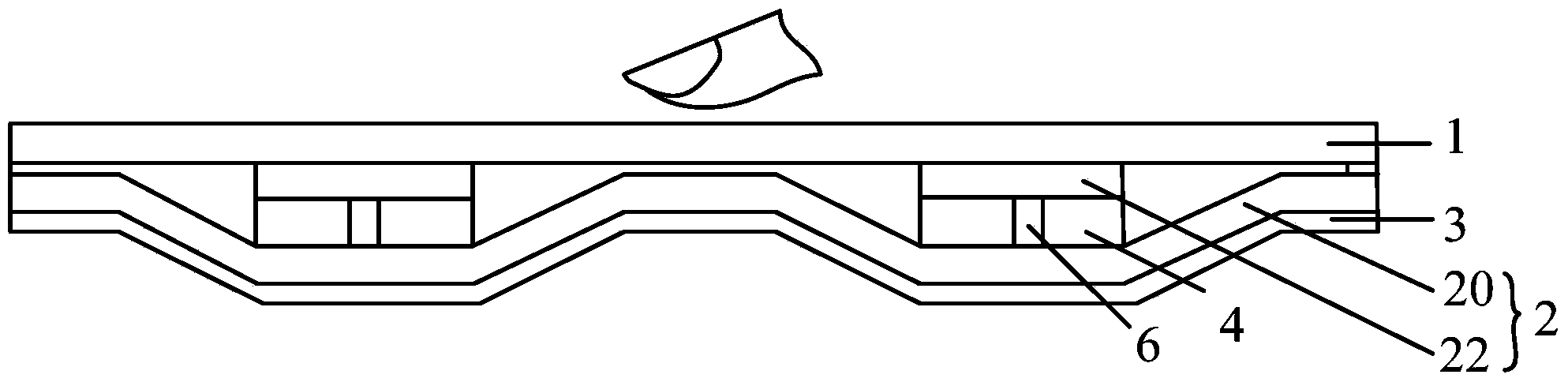

[0031] refer to Figure 1 to Figure 3 as well as Figure 6 As shown, in the vertical side view and the lateral side view of the touch screen, in order to improve the sensitivity and light transmittance of the touch screen, the present invention provides a new type of mutual capacitance touch screen, which includes: a touch substrate 1, located on the touch screen The surface of the metal support layer 2, which is located below the touch-sensitive substrate 1, supports the touch-sensitive substrate 1, and conducts current. 20 and the longitudinal support 22 are interlaced to form a network-like metal support structure, at least two transparent conductive film layers 3, including a horizontal transparent conductive film layer 30 and a vertical transparent conductive film layer 32, which are covered on the metal support layer by coating or pasting. 2, the two are electrically connected to each other, the horizontal support 20 and the horizontal transparent conductive film layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com