Etching method for silicon oxide and silicon nitride double-layer composite side wall (ON side wall)

A technology of silicon oxide and silicon nitride, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of unfavorable control of the bottom side wall width, and achieve the effect of avoiding damage and controlling the gate width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and by taking specific implementations as examples. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

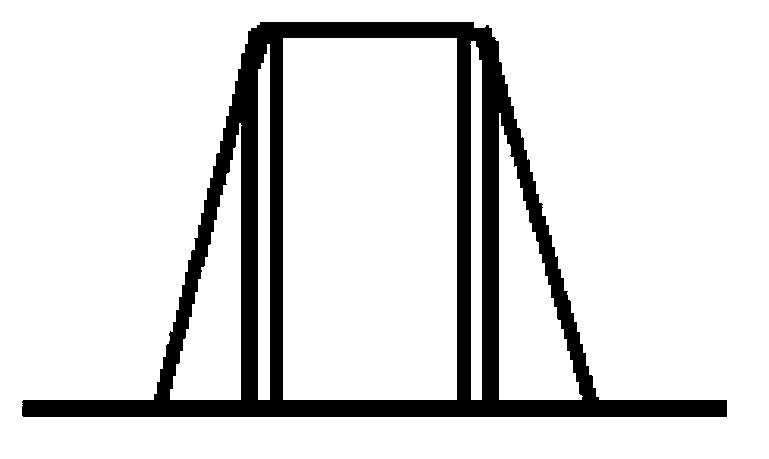

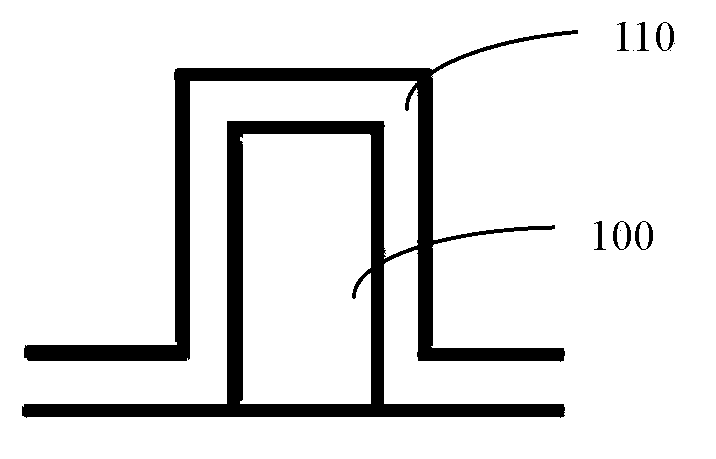

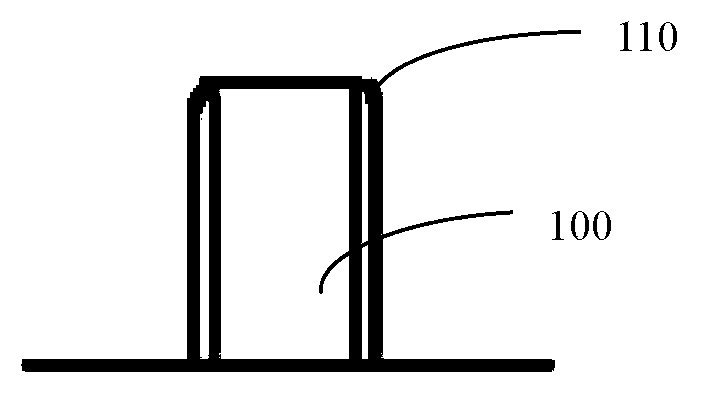

[0020] The etching method of the silicon oxide and silicon nitride double-layer composite sidewall of the present invention divides the etching of the ON sidewall into two steps of main etching and over-etching. The main etching step is not triggered to stop when it touches silicon oxide, but stops when 2 / 3 to 4 / 5 of the silicon nitride thickness is etched away, and then switches to the over-etching step, which is convenient for controlling the ON sidewall The main function of the over-etching step is to etch the remaining silicon nitride thickness and stop on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com