Low-profile high-gain panel antenna and application thereof

A flat-panel antenna, high-gain technology, applied in slot antennas, antenna supports/installation devices, radiating element structures, etc. The effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

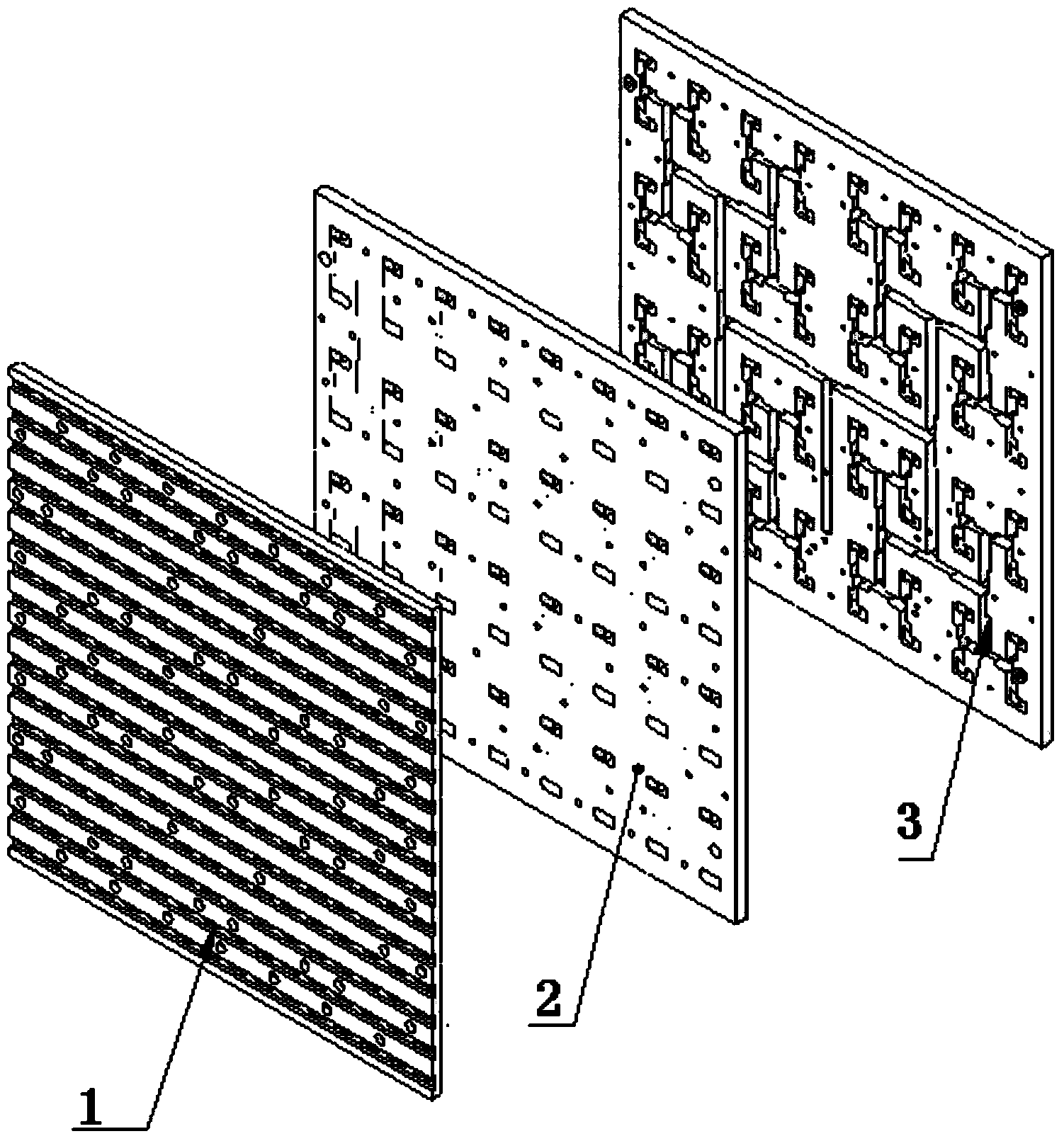

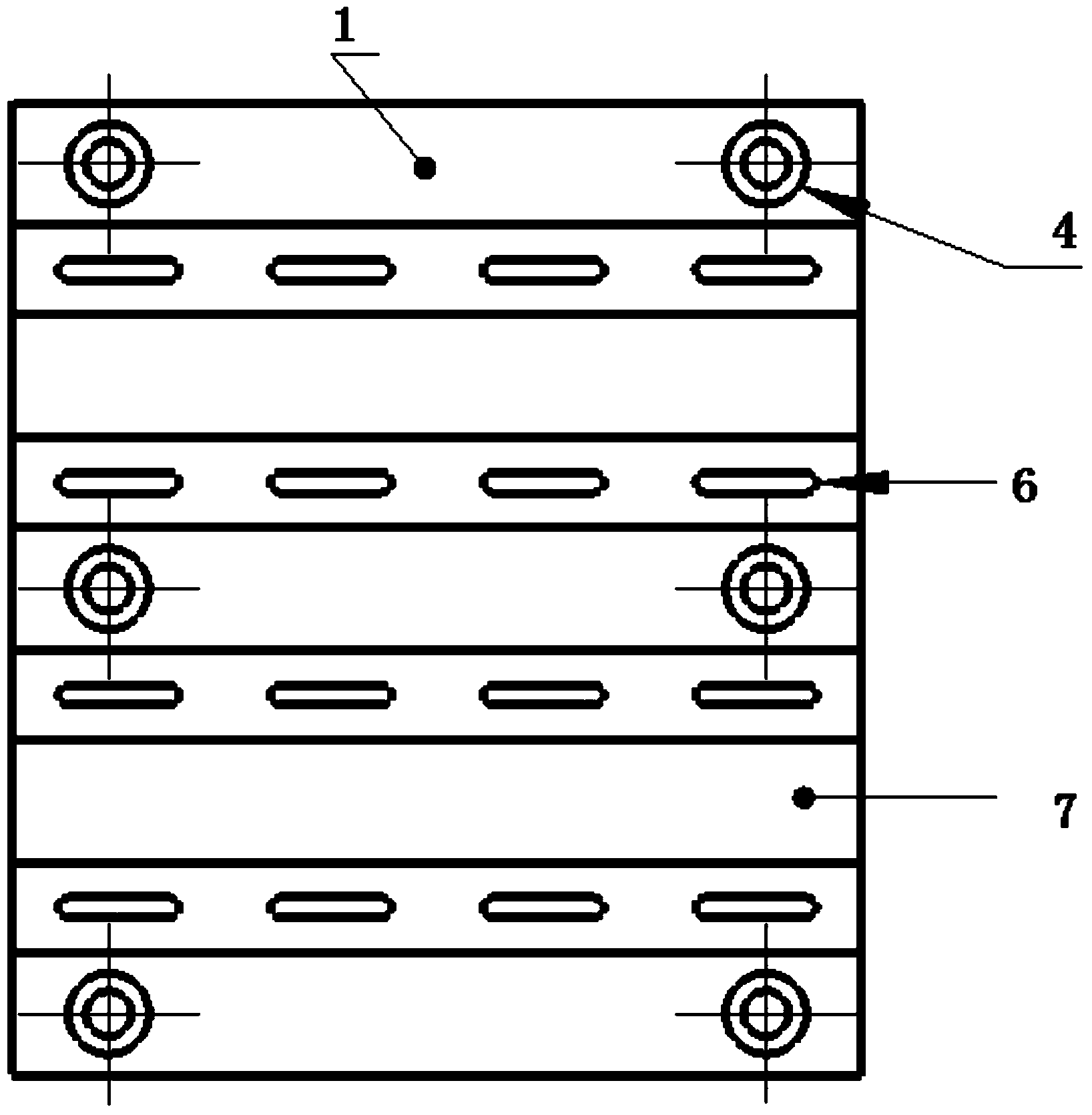

[0033] A low-profile high-gain panel antenna, including a radiation layer 1, a coupling layer 2 and a feed layer 3; the radiation layer 1 is a slot radiation layer: a radiation slot 6 is arranged on the radiation layer 1, and the radiation slot The length of 6 is half of the average wavelength of the Ku band.

Embodiment 2

[0035] A low-profile high-gain panel antenna as described in Embodiment 1, the difference is that the low-profile high-gain panel antenna has a thickness of 19-22 mm.

Embodiment 3

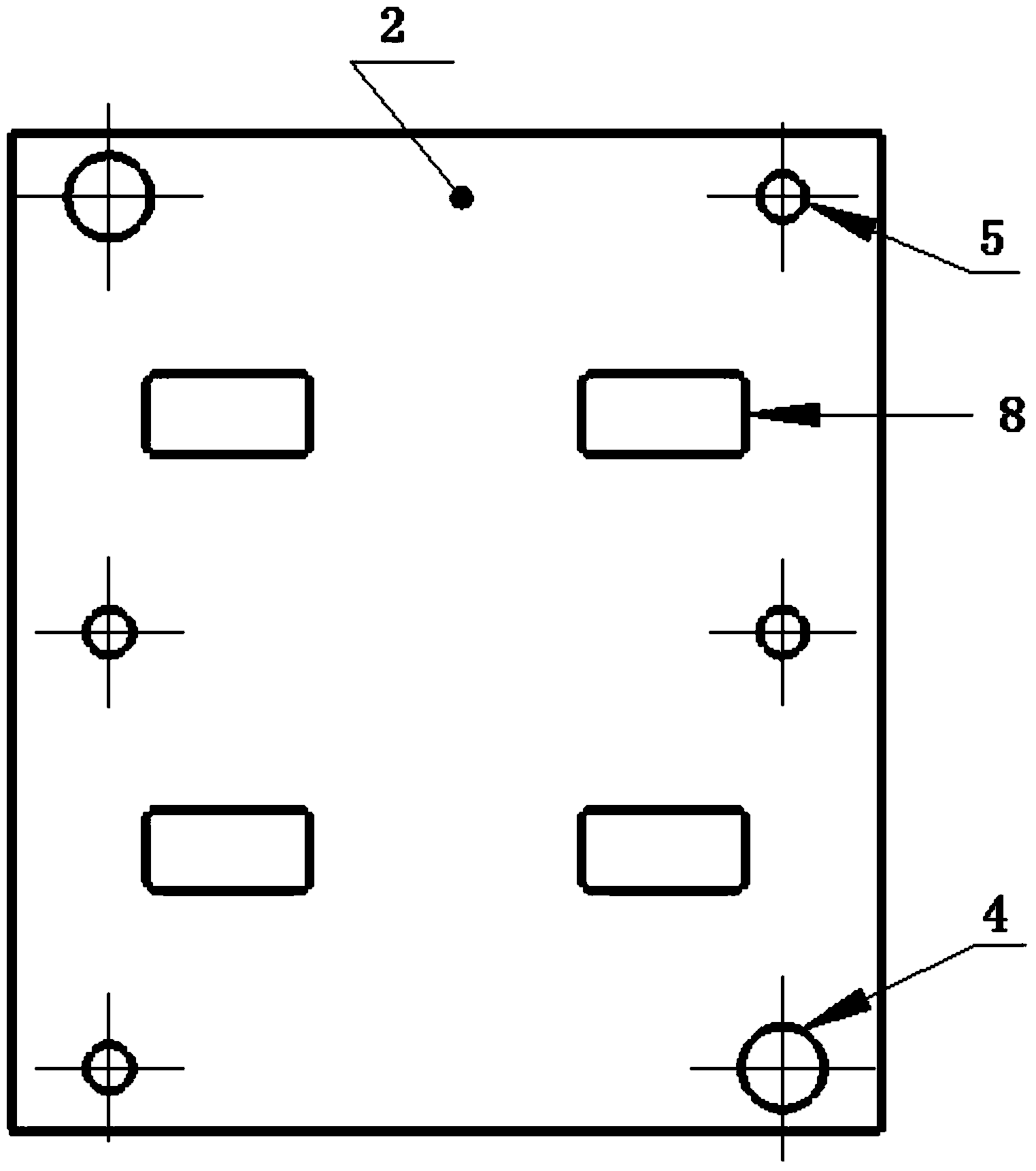

[0037] A low-profile high-gain panel antenna as described in Embodiments 1 and 2, the difference is that the radiation layer 1, the coupling layer 2 and the feeding layer 3 are fixed and installed in sequence through the positioning hole 4, the connecting hole 5 and the screw matching sequence .

[0038] The slit length of the radiating slit 6 is 11-13mm, and the slit width of the radiating slit 6 is 1.7-2.2mm.

[0039] Multiple coupling units are arranged on the coupling layer 2 , wherein a single coupling unit includes four coupling cavities 8 .

[0040] The feed layer 3 includes a plurality of feed units, the single feed unit corresponds to the coupling unit, the single feed unit includes a feed waveguide 9 and a power splitter 10, and adopts a waveguide T-branch matching method , a capacitive resistance step 12 is set at the joint of the feeding waveguide 9 .

[0041] The size of the feeding waveguide 9 is a=13.2mm, b=6.6mm.

[0042] The side length of the capacitive re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com