A battery pack application node and matrix battery management system and implementation method

A battery management system and battery system technology are applied in battery pack application nodes and matrix battery management systems and implementation fields, which can solve the problems of shortened battery pack life, shortened lifespan, and inability to control current, so as to improve work efficiency and service life, Cost-effective, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

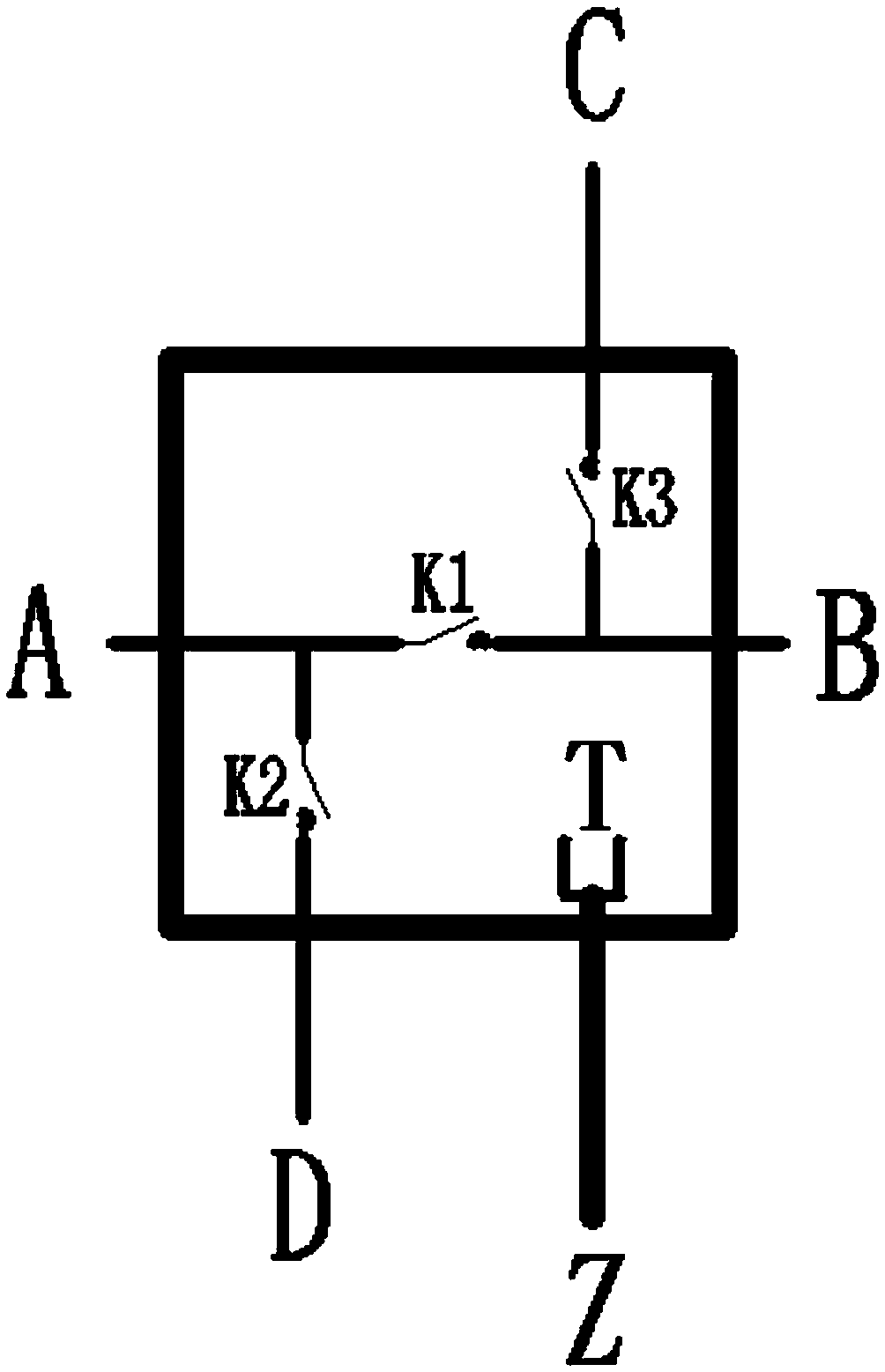

[0048] Such as figure 1 As shown, the battery pack application node is a circuit board composed of the first switch K1, the second switch K2 and the third switch K3 connected by lines, and five connection points are arranged on the circuit board, wherein the first connection point A. The second connection point B, the third connection point D, and the fourth connection point C are single contacts for connecting power lines, and the fifth connection point Z is a compound contact for connecting to a communication bus. The first connection point A and the second connection point B are set at both ends of the first switch, that is, the first switch K1 is used to connect the first connection point A and the second connection point B, and then respectively connect the two waiting points at the left and right ends of the switch. Connect the positive pole and the negative pole of the battery, and the third connection point D is set between the first connection point A and the second c...

Embodiment 2

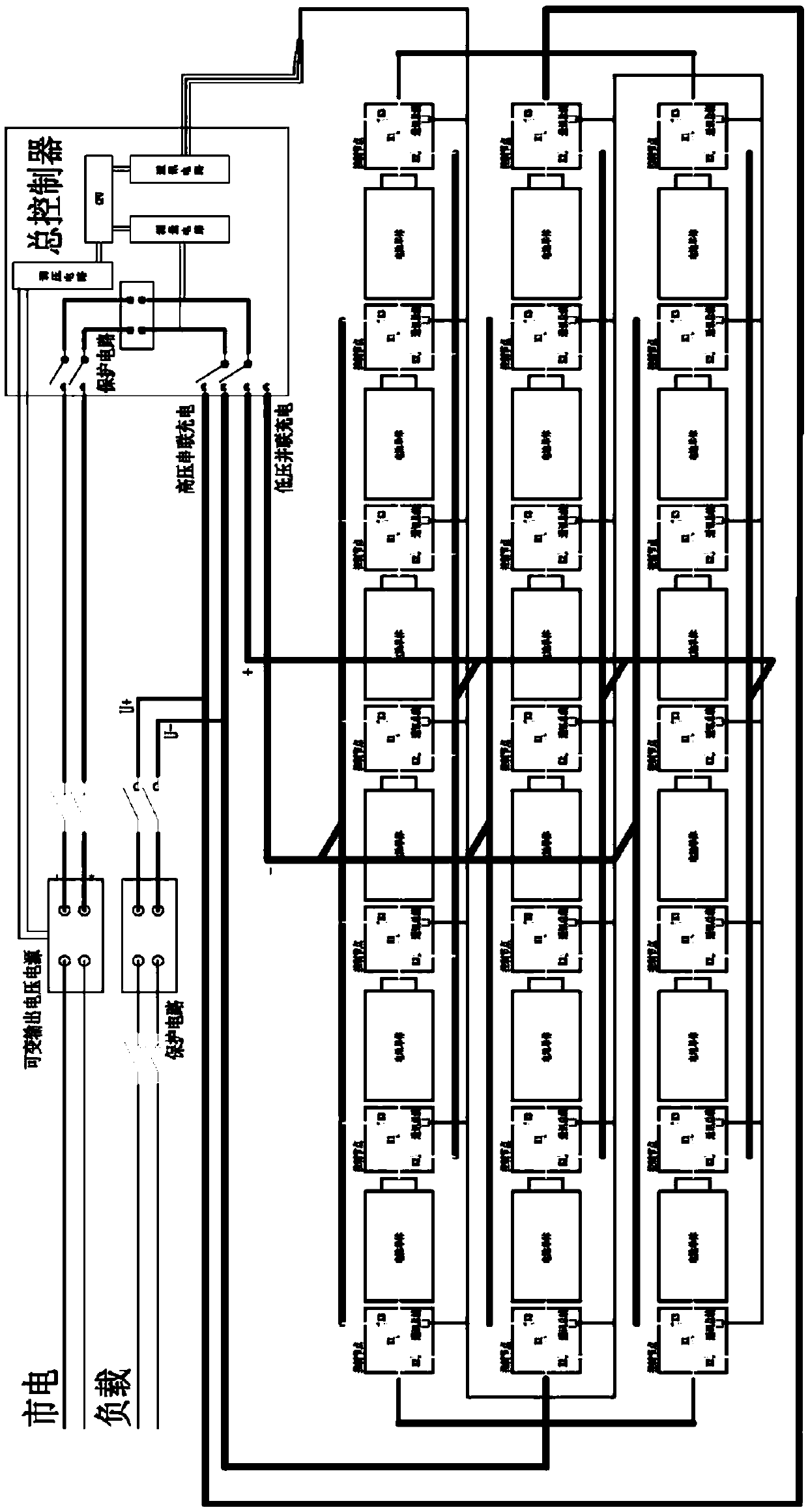

[0065] Such as figure 2 As shown, the matrix battery management system with the battery pack application node described in Embodiment 1 includes a general controller, a battery pack application node and a battery cell, and battery cells are respectively connected to both sides of the battery pack application node. The first connection point A of the application node of the battery pack is connected to the positive pole of the battery cell at the left end, and the second connection point B is connected to the negative pole of the battery cell at the right end. The matrix battery management system includes a number of series units formed by alternating arrangement of battery cells and battery pack application nodes, a general controller and a variable output DC switching power supply (Taiwan MEANWELL SPV-300-SPEC). The controller (PLC) is an execution unit that can execute logic programs. The controller is equipped with a single-chip microcomputer (Siemens 200 series CPU), whic...

Embodiment 3

[0067] The implementation method of charging and discharging of the matrix battery management system described in Embodiment 2, the implementation steps are as follows:

[0068] The operation of parallel or combined charging and combined discharging is realized by uniformly switching the three switches of all the above-mentioned battery pack application nodes, that is, when discharging: the first switch K1 is closed, the second switch K2 and the third switch K3 are turned off; when charging: The first switch K1 is turned off, the second switch K2 and the third switch K3 are turned on, and the instruction of switching the switch and the scanning of the working data of each battery pack application node are completed by the general controller through the communication bus T.

[0069] The specific working process includes the following steps:

[0070] Discharge process:

[0071] (1) The general controller notifies all nodes to switch to the discharge state through the network br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com