hid arc tube and its manufacturing method, lighting device and lighting system

A lighting device and arc tube technology, applied in the lighting field, can solve the problems of inconvenient operation, difficulty in ensuring pole spacing and coaxiality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the content of the present invention clearer and easier to understand, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

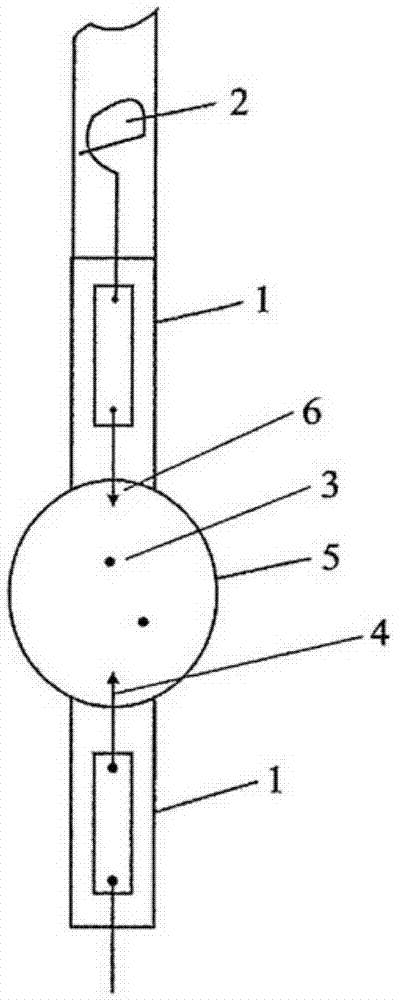

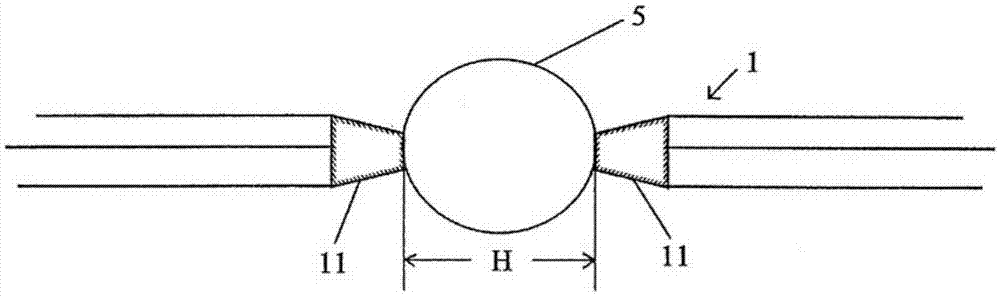

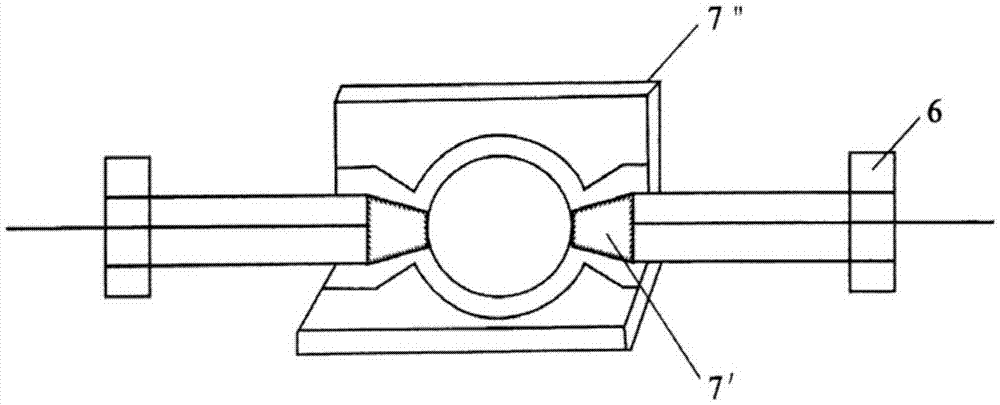

[0049] figure 1 It shows the so-called one-sealing method used in the prior art to seal the HID arc tube. The exhaust process in this method is to connect another one in the middle of the arc tube in addition to using quartz glass to make medium and high-power HID. Except for the exhaust on the exhaust pipe (practice has proved that this method destroys the geometric size of the discharge cavity, is not conducive to the metal halide cycle, affects the light output, life and light color stability), it is all done by hand, and It is carried out in the glove box while wearing the gloves on the glove box, so it is difficult to ensure the pole spacing and coaxiality of the two electrodes in the HID arc tube, so that the qualified rate and consistency of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com