Fruit cutter

A shredder and fruit technology, which is applied in the field of household appliances, can solve the problems that it is difficult to achieve fine crushing effect, it is difficult to ensure the heat dissipation effect, and the motor is damaged by overheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

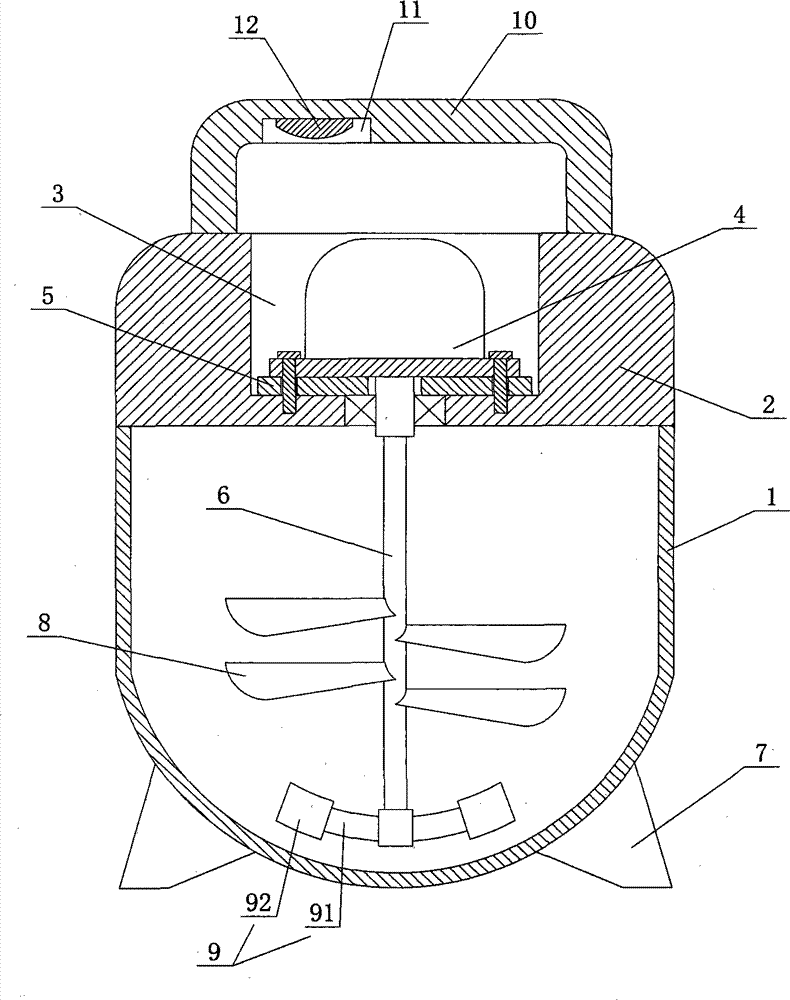

[0012] Referring to the accompanying drawings, the fruit shredder of the present invention comprises a cup body 1 with an open top and a cup cover 2 installed on the opening of the cup body 1, the top surface of the cup cover 2 is provided with a groove 3, and the bottom wall of the groove 3 A motor 4 is installed on the top and a rubber pad 5 is placed between the motor 4 and the bottom wall of the groove 3. The motor 4 is installed in the groove 3. The motor 4 can fully dissipate heat through the notch of the groove 3, and the rubber pad 5 can be set to reduce the heat dissipation. vibration and noise. The power output shaft of the motor 4 passes through the bottom wall of the groove 3 and extends into the cup body 1, the cup body 1 is provided with a rotating rod 6 connected with the power output shaft of the motor 4, and the bottom of the cup body 1 is hemispherical And the circumferential spacer ring of the outer bottom wall of the cup body 1 is provided with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com