Manipulator taking mechanism

A technology of reclaiming mechanism and manipulator, applied in metal processing equipment, feeding device, stripping device, etc., can solve the problems of rising labor costs, and achieve the effects of stable power output, reduced production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

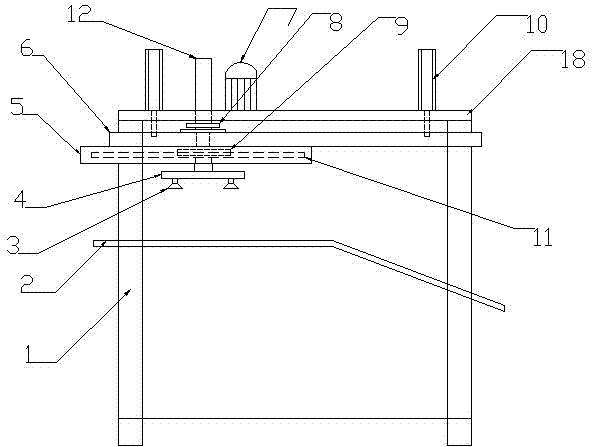

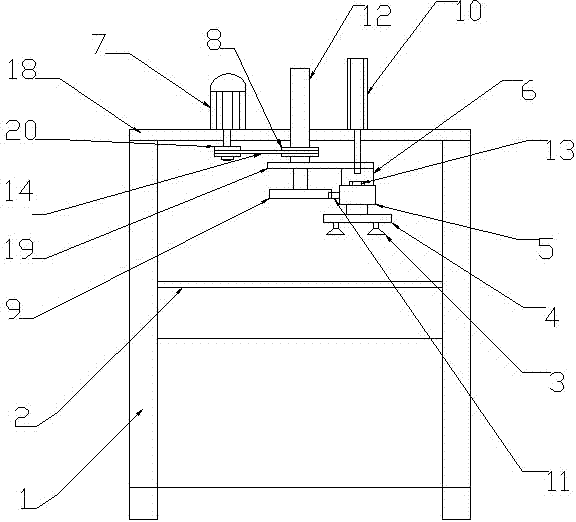

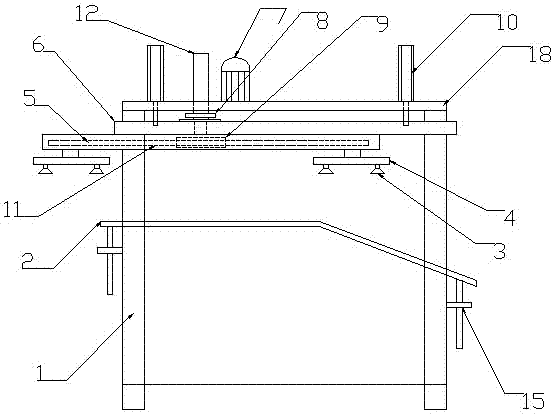

[0029] A manipulator retrieving mechanism is used for retrieving and conveying stamping parts between two stamping equipment, including a frame 1, a retrieving vertical moving device, a retrieving horizontal moving device, a retrieving device and an electric control device.

[0030] like Figure 1-2 As shown, the frame 1 includes a support base and a fixed platform 18 arranged above the support base. The frame 1 also includes an intermediate platform 2 arranged in the middle of the frame for the transfer channel of the stamping parts between the two punching machines. The inclined platform, the horizontal platform and the inclined platform are fixedly connected.

[0031] The vertical moving device for taking materials comprises a horizontally arranged first profile support 6 and a cylinder 10 for driving the first profile support 6 to move vertically. The cylinder 10 is fixedly arranged on a fixed platform 18. The support 6 is fixedly connected and drives the first profile s...

Embodiment 2

[0040] The rest are the same as in Embodiment 1, the difference is that the vertical movement drive device also includes a vertical guide assembly, the vertical guide assembly includes a guide seat and a guide rod fixedly arranged on the fixed platform, the guide seat is provided with a through hole in the vertical direction, and the guide The rod slides through the through hole and is fixedly connected with the first profile bracket.

[0041] Under the action of the vertical guide assembly, the reclaiming device has a clear direction and reliable movement when retrieving materials.

[0042] The second profile support is arranged in parallel with the first profile support and is slidably connected through the pulley slide rail.

Embodiment 3

[0044] The rest is the same as that of Embodiment 2, except that when the product size is large, the reclaiming device can be provided with two or more adsorption member brackets.

[0045] Setting more than two adsorption component brackets can simultaneously absorb the head and tail parts of the stamping parts, shorten the transmission stroke during the transmission process, increase the transmission speed, and reduce the size of the entire manipulator retrieving mechanism at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com