Cutting machine for rubber hoses with fiber woven layers

A fiber braided layer and rubber hose technology, which is applied in metal processing and other directions, can solve the problems of inconsistent hose length, uneven cut, high cost, etc., and achieve good cut quality and length consistency, high processing efficiency, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail

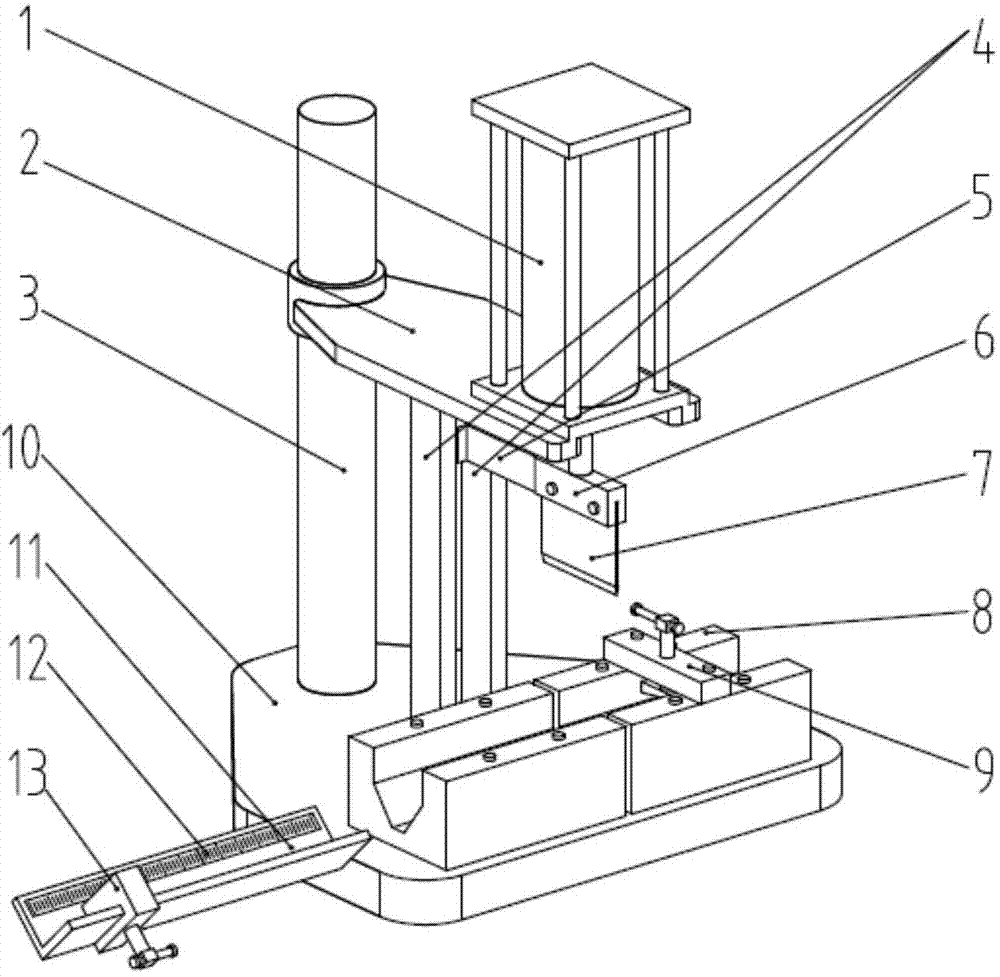

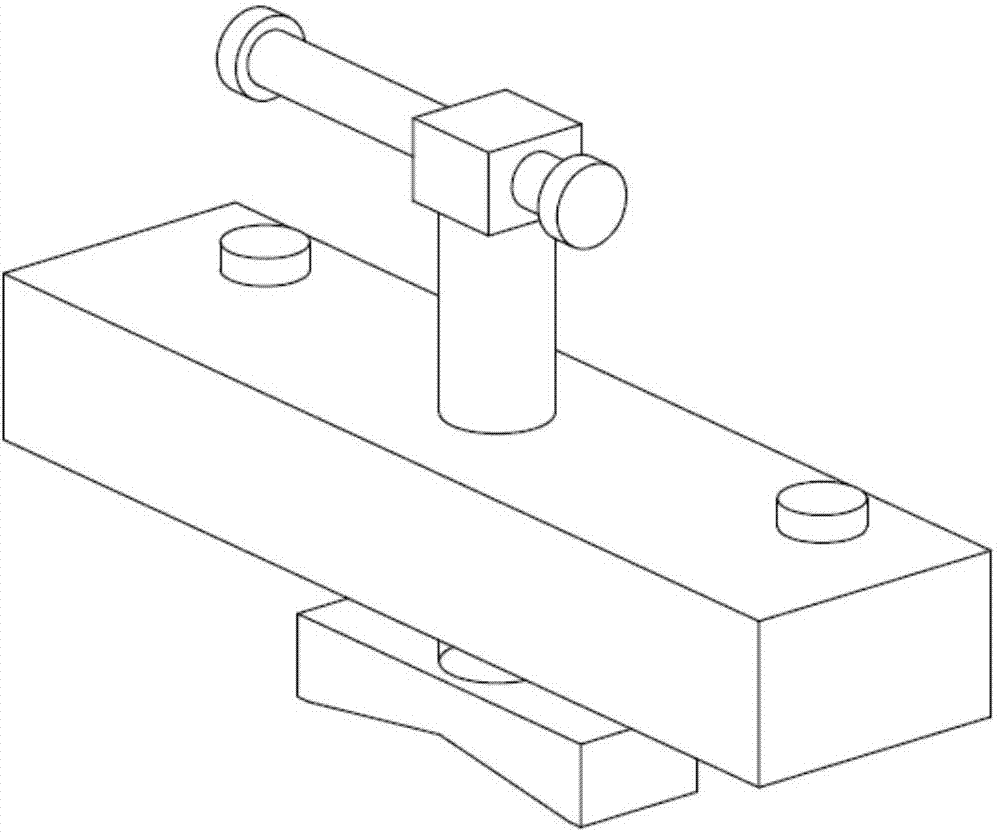

[0017] Such as figure 1 As shown, when cutting the fiber-braided rubber hose, first use the measuring ruler (12) to measure the required length of the hose to be cut, slide the sliding block (13) to the designated position of the measuring ruler (12), and lock the sliding gear block (13), put the hose into the V-shaped groove, and clamp the hose through the hose clamping device (9). Step on the pneumatic foot pedal, the cylinder piston drives the cutter (7) to cut the hose downward, release the pneumatic pedal after the pipe cutting is completed, the piston drives the cutter (7) to leave the hose upward, and loosen the hose clamp Tighten device (9), take off flexible pipe, just finished once cutting of flexible pipe, repeat above-mentioned operation and just can cut flexible pipe quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com