Proceeding self-locking device

A self-locking device and self-locking technology, applied in the field of mobile machinery accessories, can solve the problems of inability to achieve slope position locking, inability to achieve heavy load, insufficient reliability, etc., and achieve the effects of simple structure, simplified equipment, and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with embodiment.

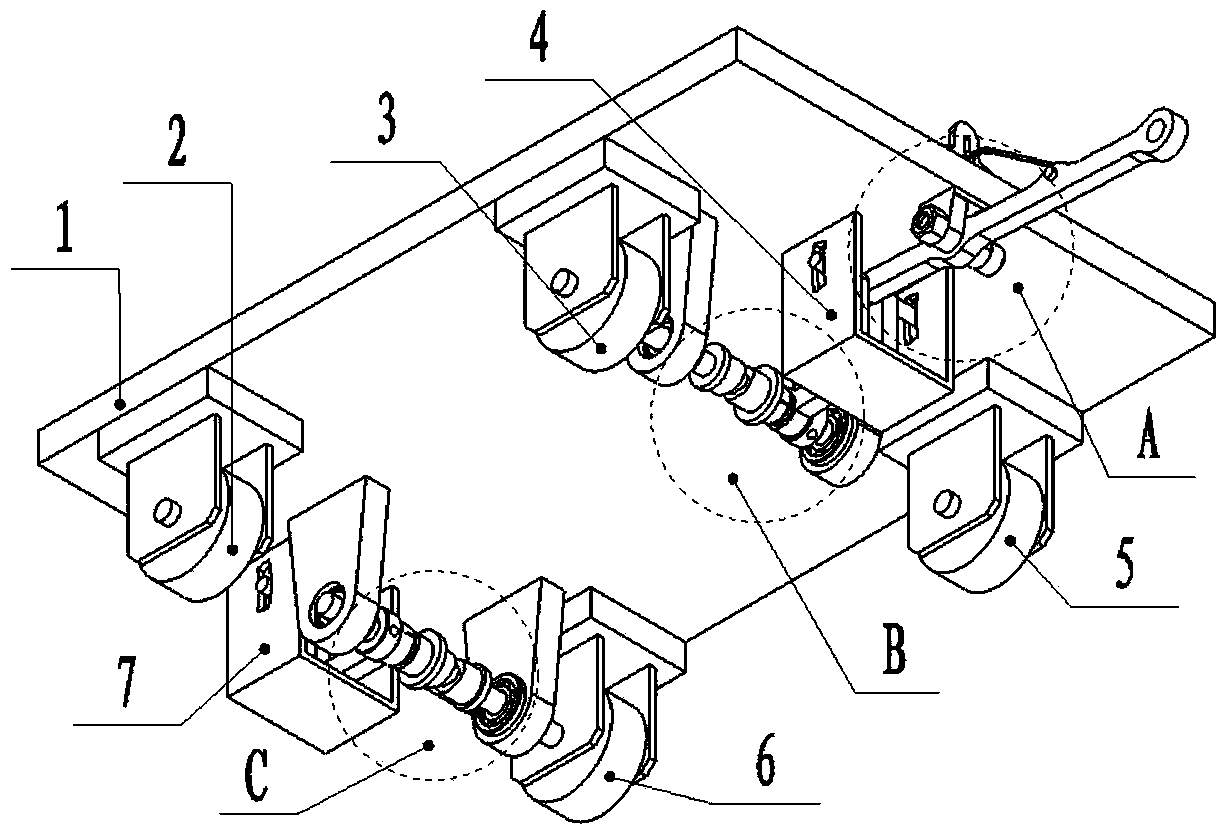

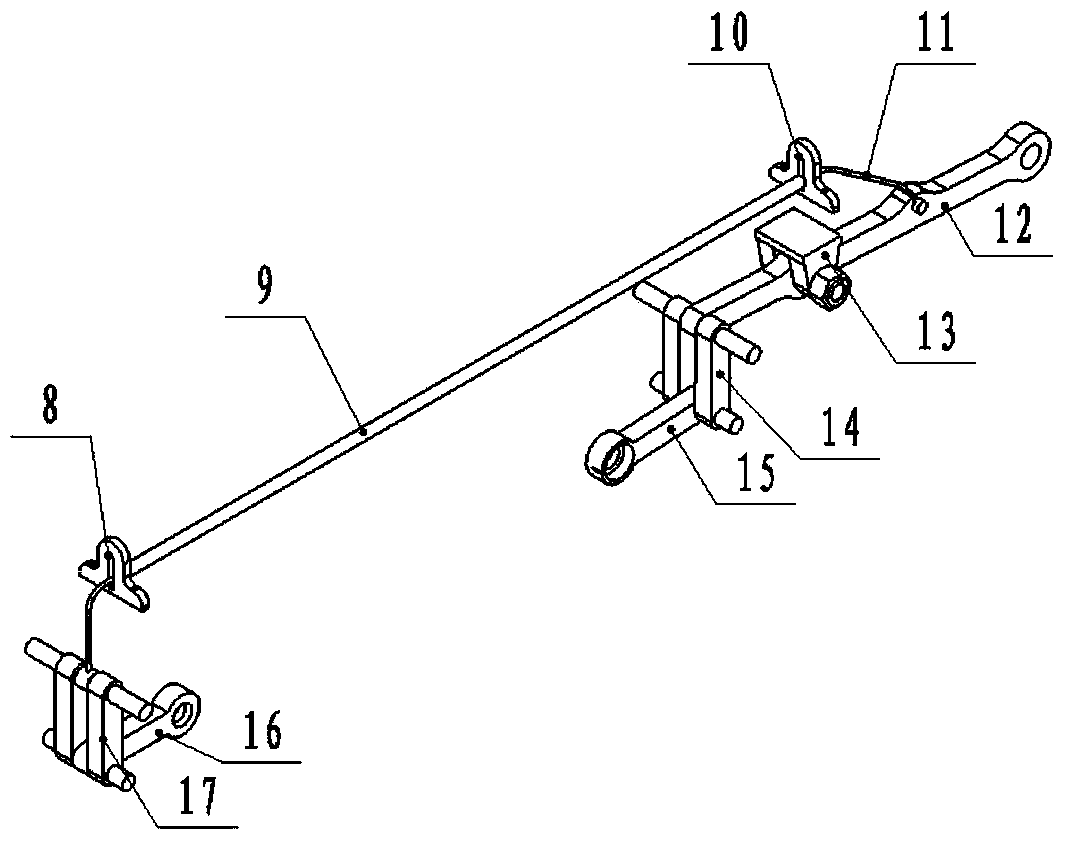

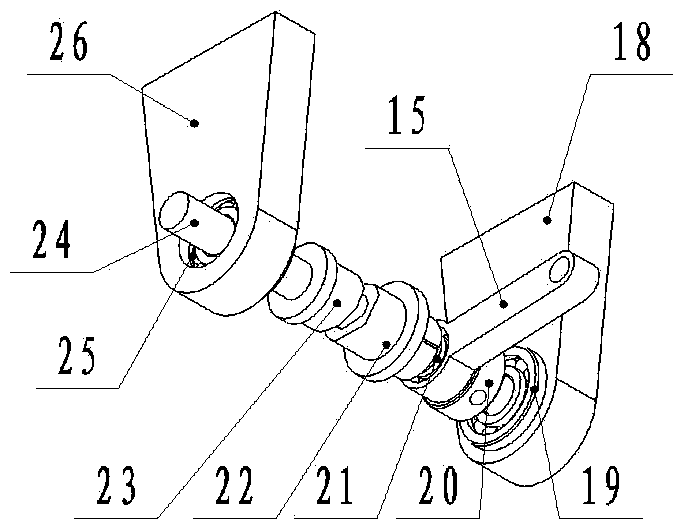

[0044] The present invention is mainly realized through the following technical solutions: a traveling self-locking device, which consists of a transmission system A, a self-locking clutch system I B, a self-locking clutch system II C, a fuselage bottom plate 1, a left front wheel 2, a left rear wheel 3, Connecting piece limiting frame Ⅰ4, right rear wheel 5, right front wheel 6, connecting piece limiting frame Ⅱ7, connecting rod Ⅰ14, connecting piece Ⅰ15, connecting piece Ⅱ16 and connecting rod Ⅱ17, of which left front wheel 2, left rear wheel 3. The right rear wheel 5 and the right front wheel 6 are fixedly connected to the four corners of the bottom surface of the fuselage bottom plate 1 via respective brackets respectively.

[0045] The hinge support 13 in the transmission system A of this embodiment is fixedly connected to the front part of the center line of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com