Self-repairing latex well cementation cement slurry as well as preparation and application thereof

A cementing cement slurry and self-repairing technology, applied in the direction of wellbore/well components, drilling composition, earthwork drilling and production, etc., can solve the problem of no self-repairing ability, improvement of cementing sheath integrity and durability The effect is limited, and it cannot meet the requirements of complex wells and gas storage wells to prevent gas channeling, corrosion resistance and damage resistance, and achieve good performance and good self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

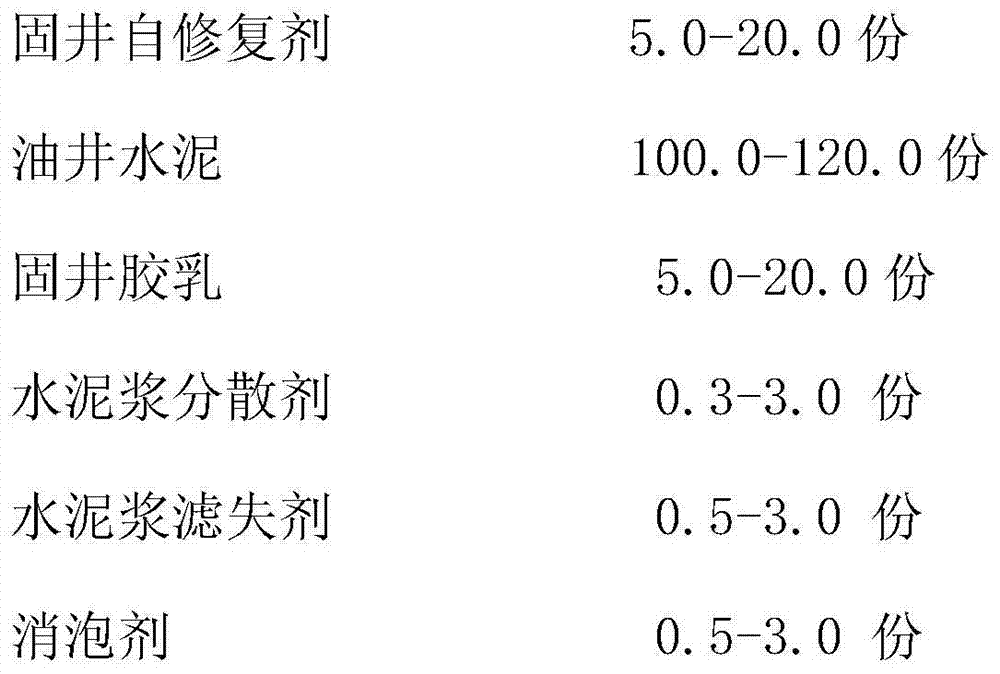

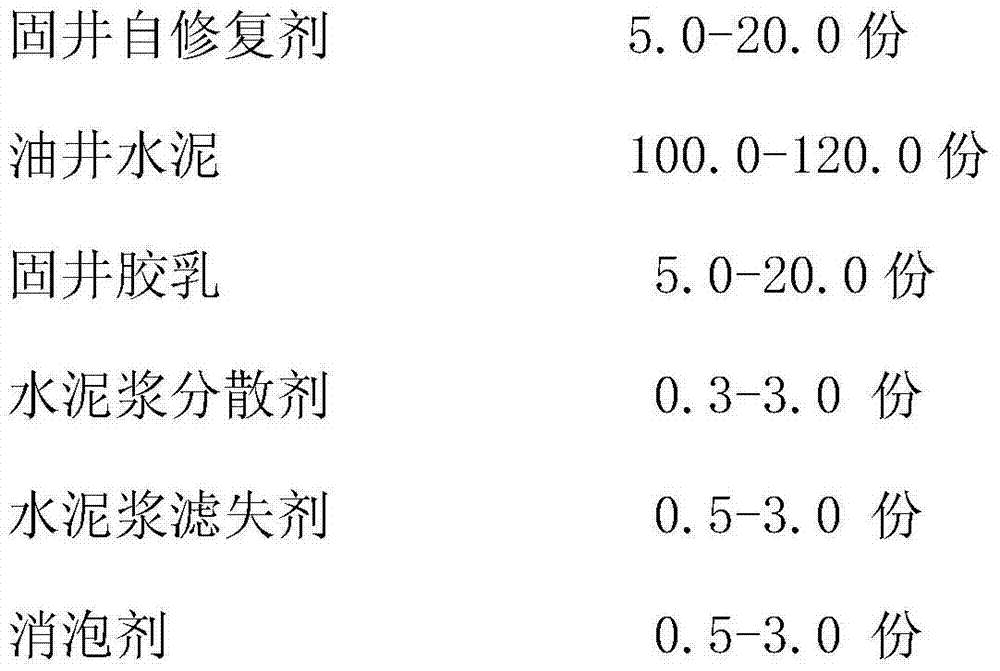

[0041] A self-healing latex cementing cement slurry system consists of the following components (parts by weight):

[0042]Rare earth coordination type oil and gas well cementing cement sheath self-repair agent (self-made) 10 parts; oil well cement (product grade: G grade, product source: Sichuan Jiahua Cement Co., Ltd.) 100 parts; cementing latex (product code: JR , product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 6 parts; cement slurry dispersant (product code: SXY-2, product source: Chengdu Chuanfeng Chemical Engineering Co., Ltd.) 1.6 parts; cement slurry fluid loss agent ( Product code: BS100-2, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; cement slurry fluid loss agent (product code: BS100, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; 0.5 parts of defoamer (product code: BP-1B, product source: Chongqing Ho...

Embodiment 2

[0053] A self-healing latex cementing cement slurry system consists of the following components (parts by weight):

[0054] Rare earth coordination type oil and gas well cementing cement sheath self-repair agent (self-made) 15 parts; oil well cement (product grade: G grade, product source: Sichuan Jiahua Cement Co., Ltd.) 100 parts; cementing latex (product code: JR , product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 10 parts; cement slurry dispersant (product code: SXY-2, product source: Chengdu Chuanfeng Chemical Engineering Co., Ltd.) 1.6 parts; cement slurry fluid loss agent ( Product code: BS100-2, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; cement slurry fluid loss agent (product code: BS100, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; 0.5 parts of defoamer (product code: BP-1B, product source: Chongqing ...

Embodiment 3

[0058] A self-healing latex cementing cement slurry system consists of the following components (parts by weight):

[0059] 10 parts of cement-based permeable crystalline waterproof material masterbatch (CCCW); 100 parts of oil well cement (product grade: G grade, product source: Sichuan Jiahua Cement Co., Ltd.); cementing latex (product code: JR, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 10 parts; cement slurry dispersant (product code: SXY-2, product source: Chengdu Chuanfeng Chemical Engineering Co., Ltd.) 1.6 parts; cement slurry fluid loss agent (product code: BS100 -2, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; cement slurry fluid loss agent (product code: BS100, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; defoamer ( Product code: BP-1B, product source: Chongqing Hongsheng Oil and Gas Field Explo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com