Metal coating as well as preparation method and application thereof

A coating and metal technology, applied in the field of metal coatings and its preparation, can solve the problems of inconvenience, stains, unmentioned self-healing performance, hydrophobic performance and stability performance, and achieve good protection ability, broad application prospects, good The effect of self-healing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

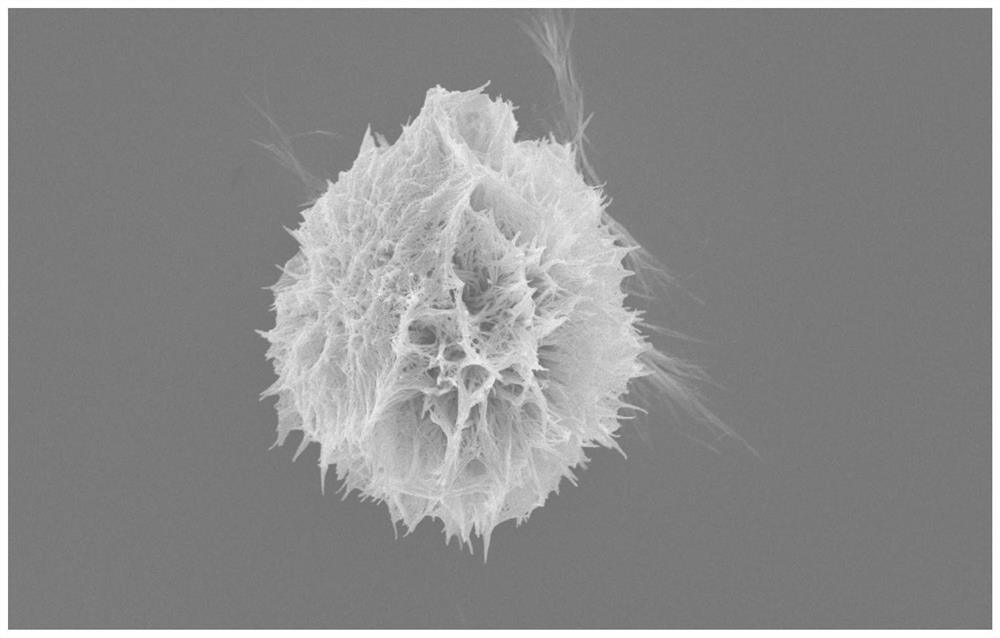

Image

Examples

preparation example 1

[0043] In a specific embodiment, the self-repairing polyurethane elastomer was prepared by: 6 parts by mass of 3,6-disulfide-1,8-octanediol was dissolved in DMSO as a chain extender, and the 25 was added thereto. The molecular weight of the substantially 1000-3000 is 1000 to 3,000 polyurethane prepolymers, after 24 h at 50 ° C, soaking the reaction product soaked, washing, washing, freeze, and freeze, it can obtain the self-repair Polyurethane elastomer.

preparation example 2

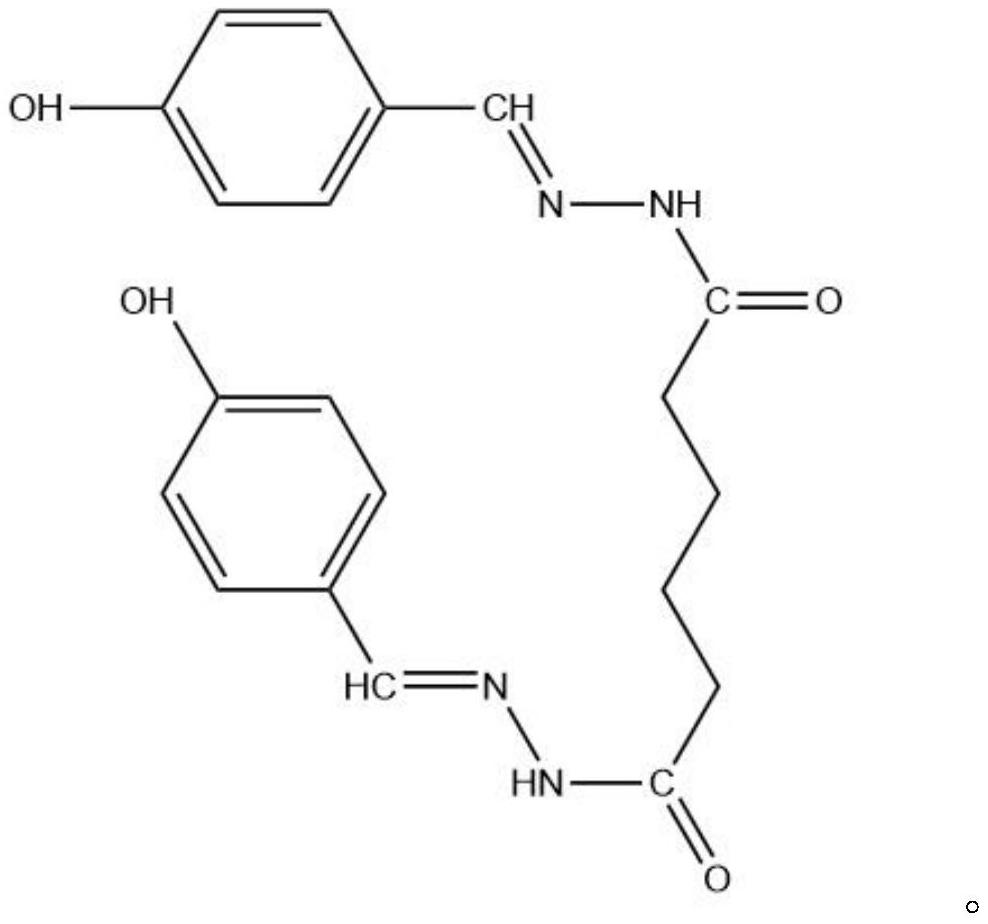

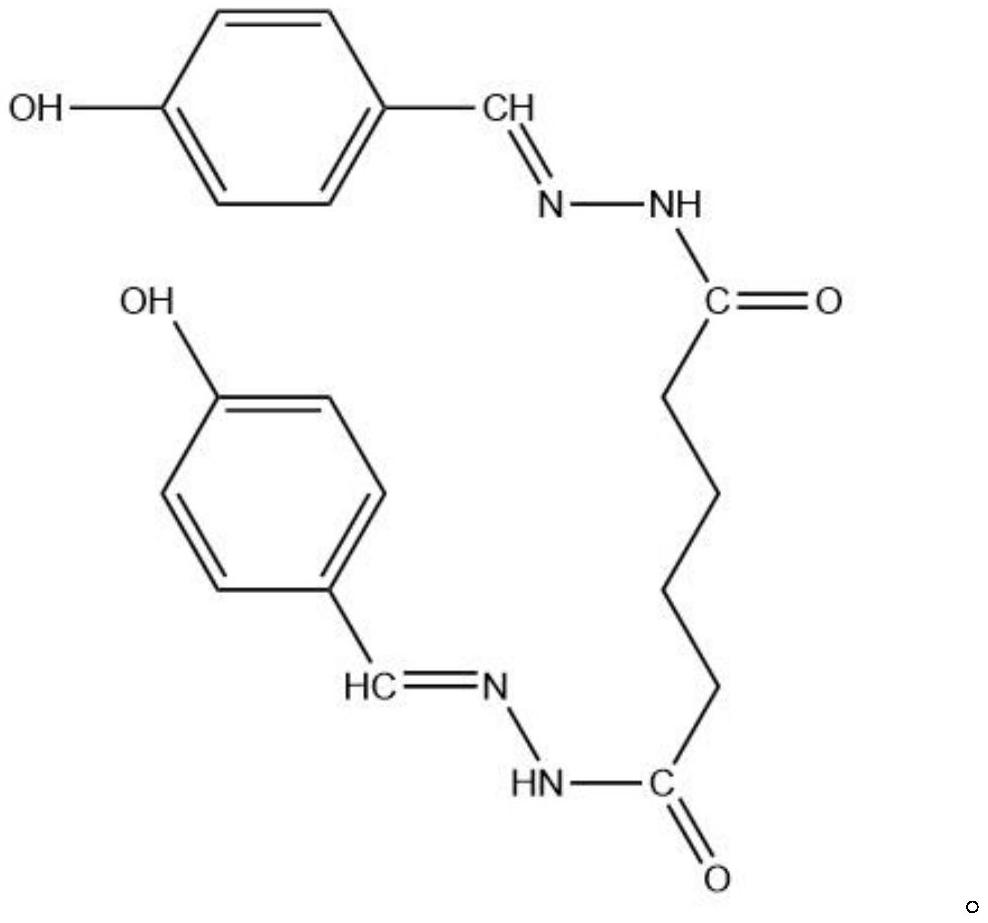

[0045] The difference from Preparation Example 1 is only that 3,6-di - 1,8-octaned diol is replaced by the same mass N'1, N'6 bis ((E) -4-hydroxybenzyl) Adipidyl hydrazide.

preparation example 3

[0047] In a specific embodiment, the modified filler was prepared in the following manner:

[0048] Step (1), 100 kg of resin filler silica was dried under 100-120 ° C for 4-6 hours, and then cooled to normal temperature under vacuum conditions, the resin filler of 0.8 kg was taken, and it was treated with 20 L toluene. Mixing, the mixture was dispersed at room temperature for 30-60 min to give a suspension mixture, and 0.364 kg of silane coupling agent KH-550 was added to the suspension mixture, and the ultrasonic treatment suspended mixture was 5-10 min, and then carried out at 90 ° C. The reactive reaction was 6-8h, and the reaction liquid was completely separated at normal temperature at normal temperature, that is, the resulting insoluble material is a resin filler modified surface passing the silane coupling agent;

[0049] Step (2), the surface of the surface obtained in 10 kg step (2) is dispersed by a resin filler modified by the silane coupling agent in a aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com