Efficient hydrotreating process for inferior heavy oil and residual oil

A technology for hydrogenation of residual oil and low-quality heavy oil, applied in the field of hydrogenation, can solve the problems of difficulty in obtaining products and benefits, high density of residual oil, and high viscosity, and achieve the effects of long device operation period, slowing down pressure drop, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

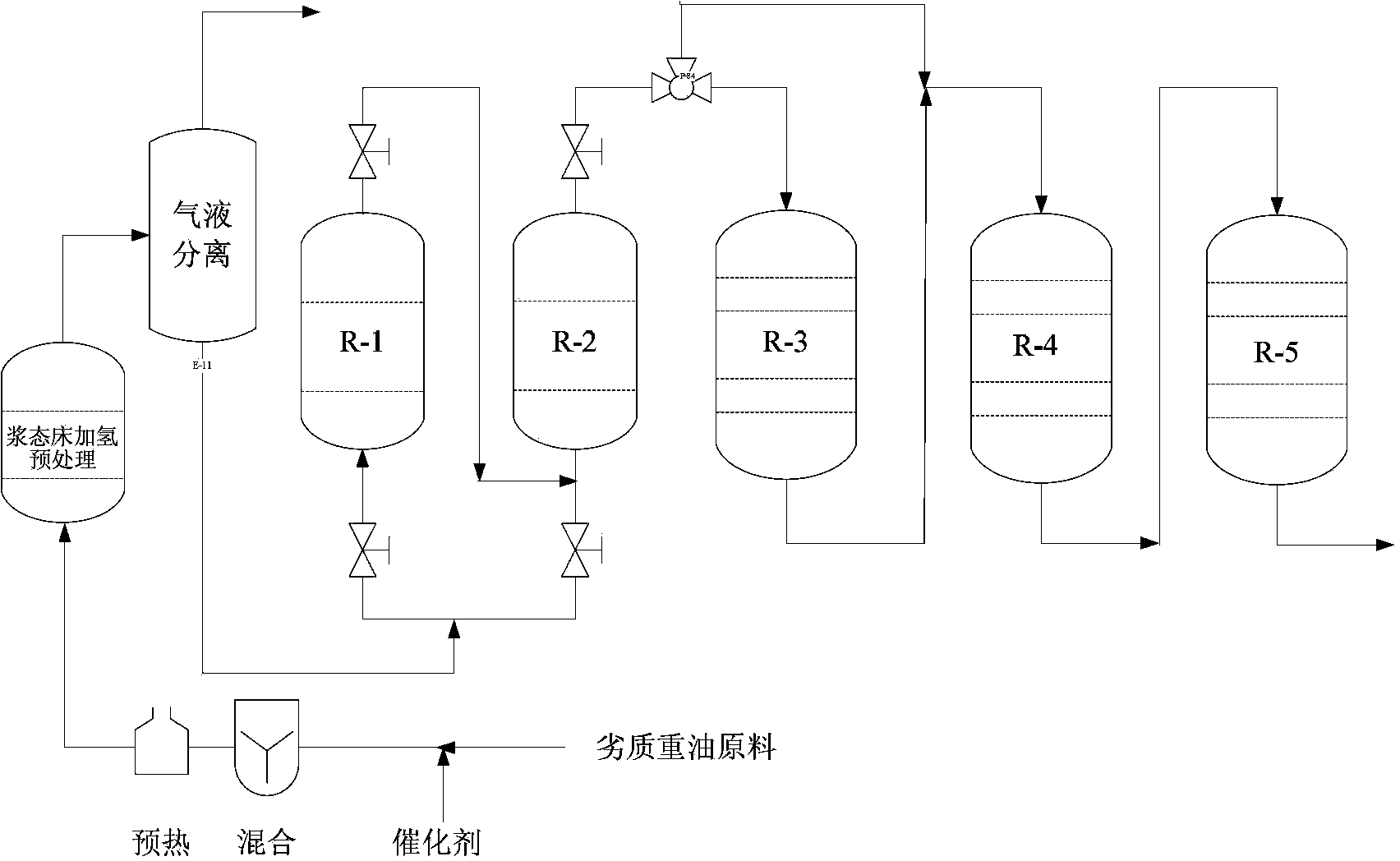

Method used

Image

Examples

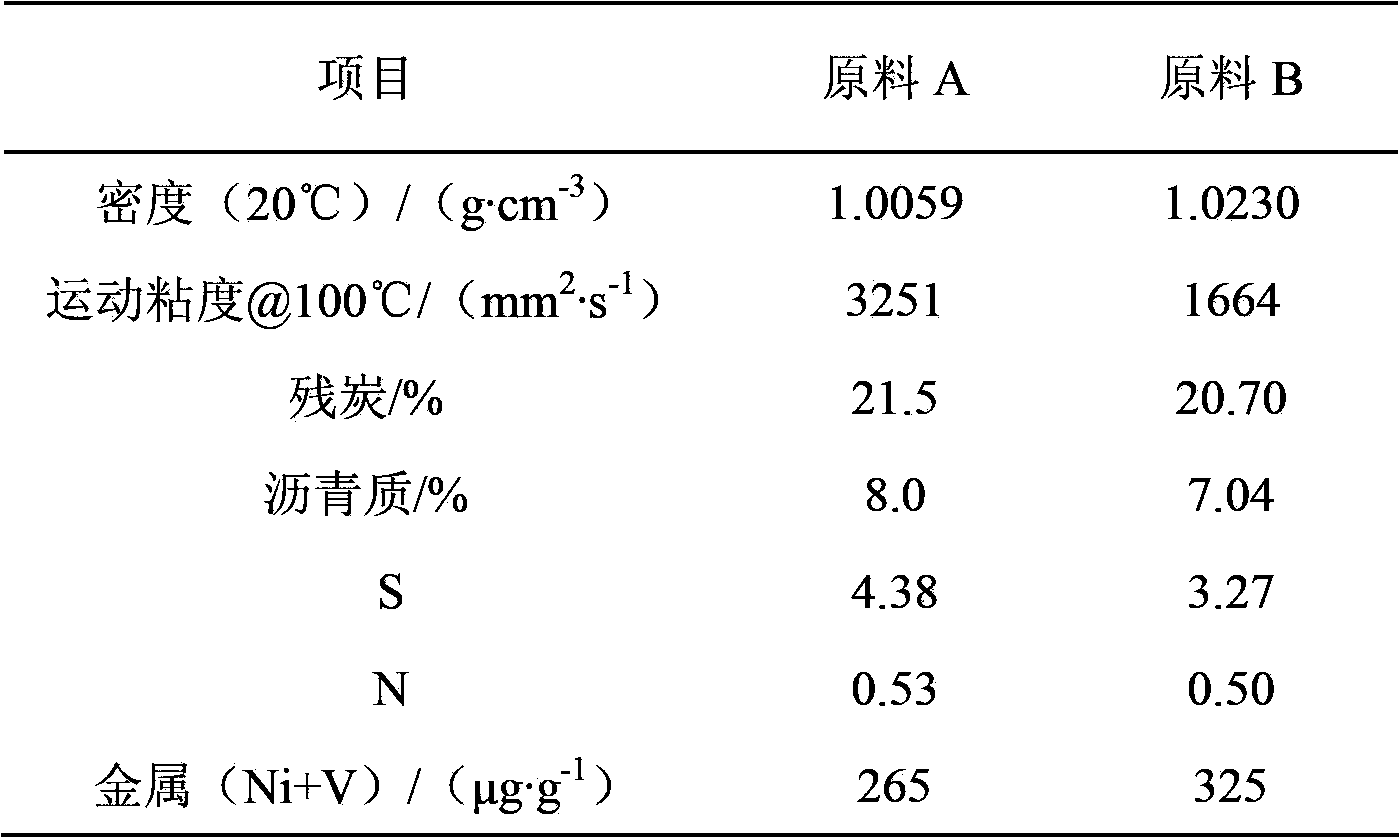

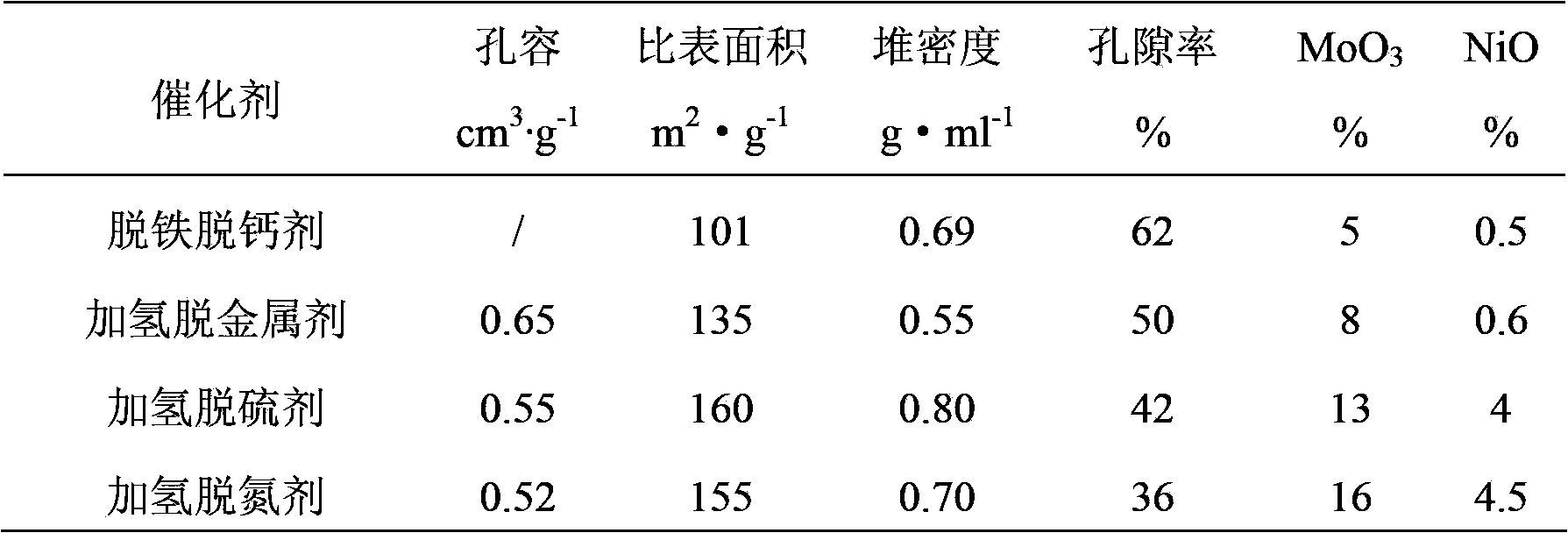

Embodiment 1

[0035] In this example, the inferior heavy oil hydrotreating process of the present invention is adopted, and raw material A is used as the raw material oil, and its properties are shown in Table 1. The slurry bed hydrogenation catalyst in the test process is prepared according to the method provided in CN101327439A embodiment 1, and the catalyst is non-supported Ni 2 P; The amount of catalyst added is 60 μg / g. The mixed raw materials and hydrogen enter the slurry bed hydrogenation reactor for reaction. After the reaction is completed, the product is separated from gas and liquid, and the liquid phase product enters the upflow type de-iron and decalcification reactors R-1 and R-2 of the hydrotreating unit, and The hydrodeferrification and decalcification catalyst is contacted to carry out the deferrification and decalcification reaction, and the reaction product directly enters the subsequent hydrotreating device without separation. The hydrodeferrification and decalcificatio...

Embodiment 2

[0038] In this example, the inferior heavy oil hydrotreating process of the present invention is adopted, and raw material B is used as the raw material oil, and its properties are shown in Table 1. The slurry bed hydrogenation catalyst in the test process is prepared according to the method provided in CN101327439A embodiment 2, and the catalyst is non-supported Ni 2 P; The amount of catalyst added is 250 μg / g. The mixed raw materials and hydrogen enter the slurry bed hydrogenation reactor for reaction. After the reaction is completed, the product is separated from gas and liquid, and the liquid phase product enters the upflow type de-iron and decalcification reactors R-1 and R-2 of the hydrotreating unit, and The hydrodeferrification and decalcification catalyst is contacted to carry out the deferrification and decalcification reaction, and the reaction product directly enters the subsequent hydrotreating device without separation. The hydrodeiron and decalcification cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com