A long-term polarization probe for pipeline cathodic protection

A cathodic protection and polarization probe technology, applied in the field of pipeline systems, can solve the problems of contaminated electrodes, failure, semi-permeable membrane blockage, etc., to avoid leakage, reduce the volume of the cavity, and reduce the current demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

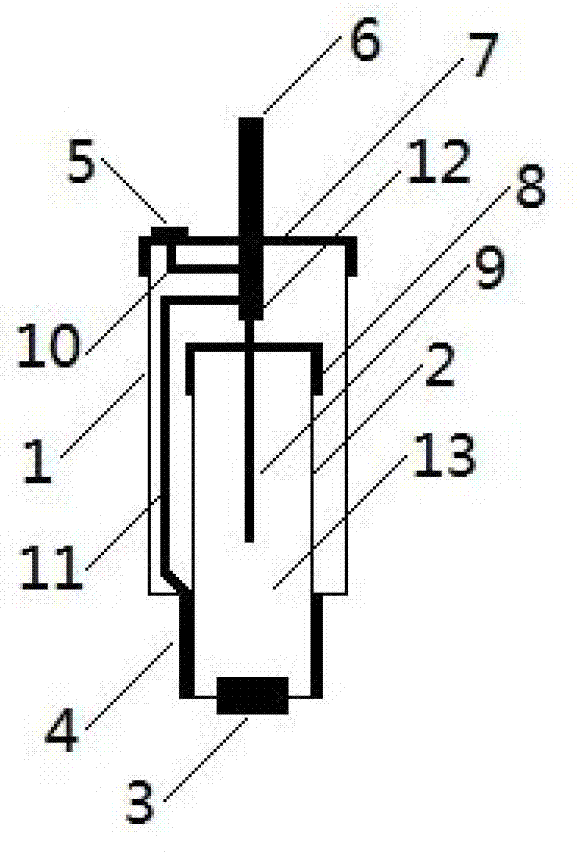

[0028] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental prototype, its composition is as follows figure 1 shown.

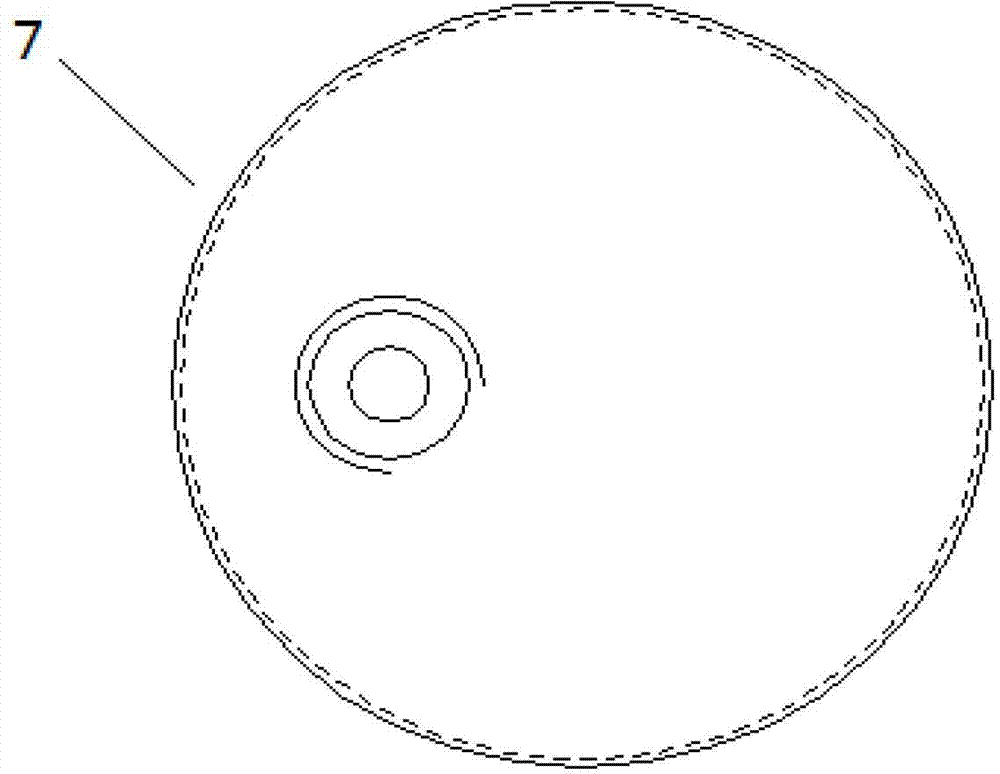

[0029] This example consists of outer cavity 1, inner cavity 2, ion-conducting polymer 3, polarization test piece 4, self-corrosion test piece 5, cable 6, outer cover 7, inner cover 8, copper rod 9, lead wire I10, lead wire II11, Composition of lead wire III12 and saturated copper sulfate solution 13. The inner cavity 2 is set in the middle and lower part of the outer cavity 1 and extends out of the outer cavity 1, and the ion-conductive polymer 3 is fixed at the bottom center of the inner cavity 2; the inner cavity 2 has an inner cover 8, and the outer cavity 1 has an outer cover 7; The self-corrosion test piece 5 is fixed on the outside of the outer cover 7, and the outer cover 7 is sealed with the outer cavity 1 through threads and gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com