Steel rib-steel tube recycled concrete combined column

A technology of recycled concrete and composite columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of multi-longitudinal steel bars, strength, shrinkage performance, poor durability, damage, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

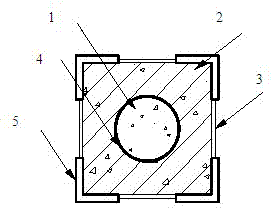

[0012] It is composed of steel frame, steel pipe, and recycled concrete, and forms a whole. The steel frame of the steel frame-steel tube recycled concrete composite column is welded by steel plates. The steel tube is located in the center of the column, and the steel frame is located at the corner of the column. It is characterized in that the concrete contains recycled concrete fragments acting as aggregates.

[0013] Recycled concrete fragments used as aggregates in concrete, with a particle size of 5mm to 30mm. According to the volume of recycled concrete per cubic meter, the recycled weight of coarse aggregate is 200kg-1400kg, cement is 400kg-600kg, water is 150kg-300kg, and fine sand is 150kg-1500kg.

[0014] 1. Weld the steel plates into steel frames according to the regulations, and the steel frames are connected by patch plates;

[0015] 2. Stand up the steel pipe and keep it vertical or at a certain angle;

[0016] 3. Stand up the steel skeleton and temporarily fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com