Porous pipe horizontal rotary spraying drill bit

A technology of horizontal swirling and multi-hole pipes, which is applied in the direction of drill bits, drilling equipment, directional drilling, etc., and can solve the problems of no pressure detection function of swirling bit, inability to solve pipeline deformation and ground uplift, and lack of deviation correction function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

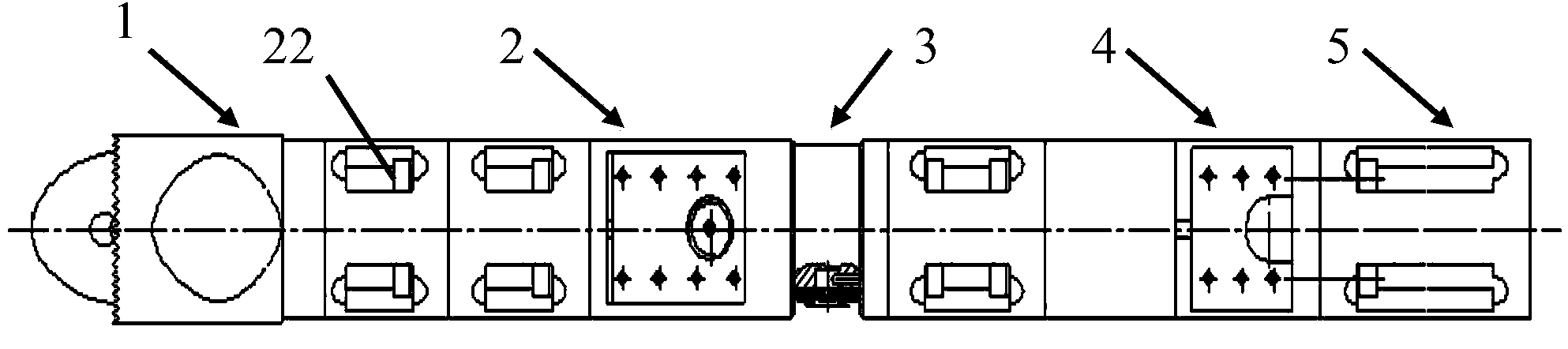

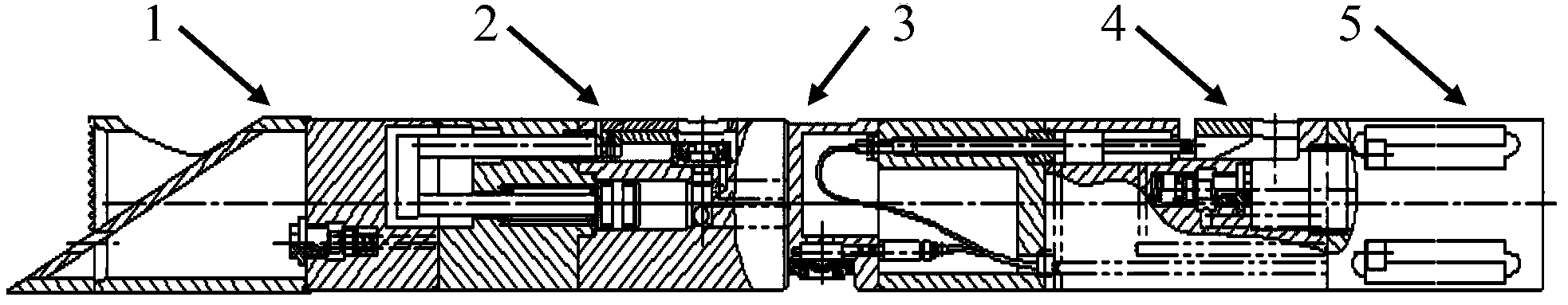

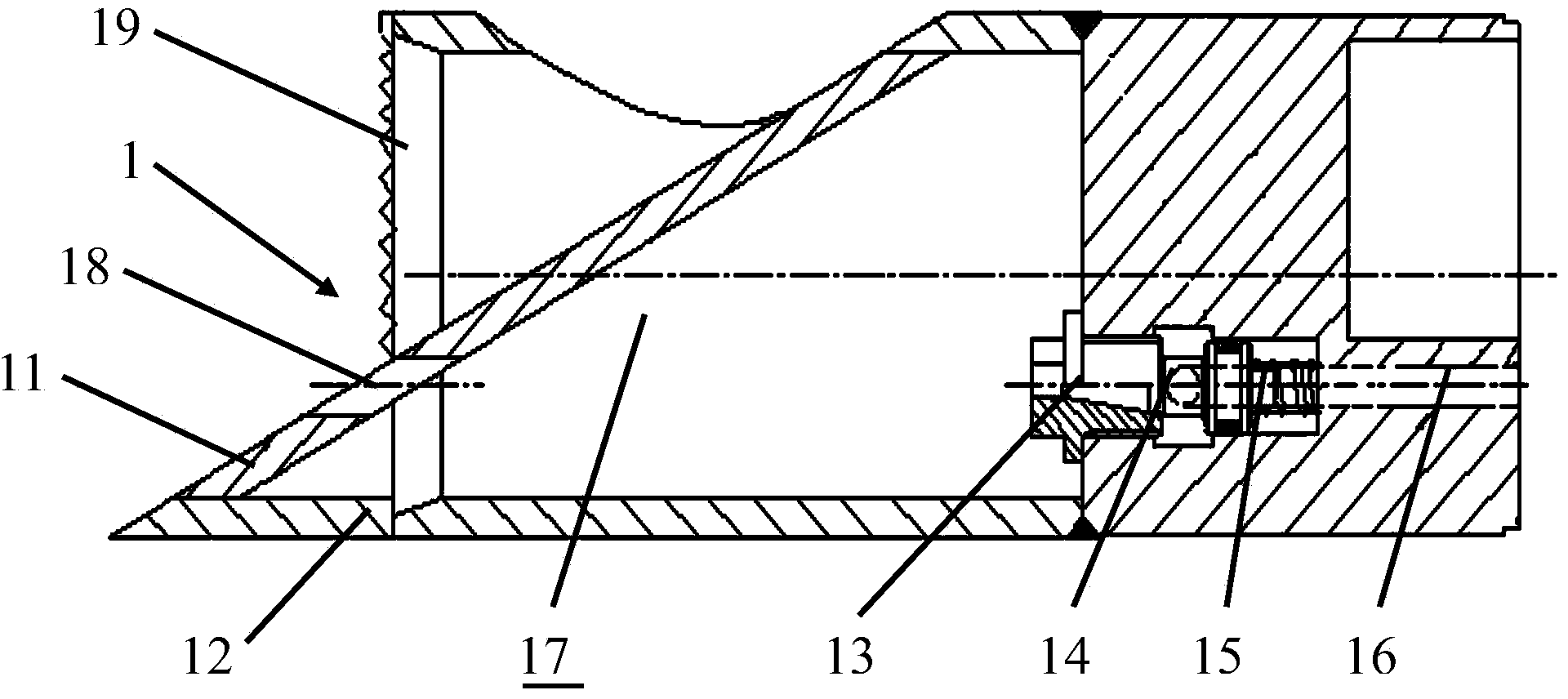

[0035] refer to figure 1 and figure 2 As shown, the present invention provides a multi-hole pipe jet jet drill bit capable of drilling deviation correction and active slurry discharge as well as detecting and controlling the pressure in the ground. It includes a drill bit section 1, a spraying section 2, a pressure measuring section 3, a slurry discharging section 4 and a connecting section 5, and the sections are sequentially connected by screws 22 coaxially. The drill bit section 1 is arranged at the head of the whole jet-jet drill bit, the spraying section 2 is used for spraying high-pressure cement slurry into the soil during the drilling process, and the pressure measuring section 3 is used for testing the process of spraying cement slurry in the spraying section. The pressure of the surrounding soil, the slurry discharge sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com