Petrochemical industry mid-span device heat integrated low temperature heat recovery system and recovery method

A low-temperature heat recovery and petrochemical technology, which is applied in the chemical industry, steam engine installations, sustainable manufacturing/processing, etc., can solve the problems of high power consumption and water consumption, increase power generation, ensure safe and stable operation, and improve The effect of economic benefits and technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

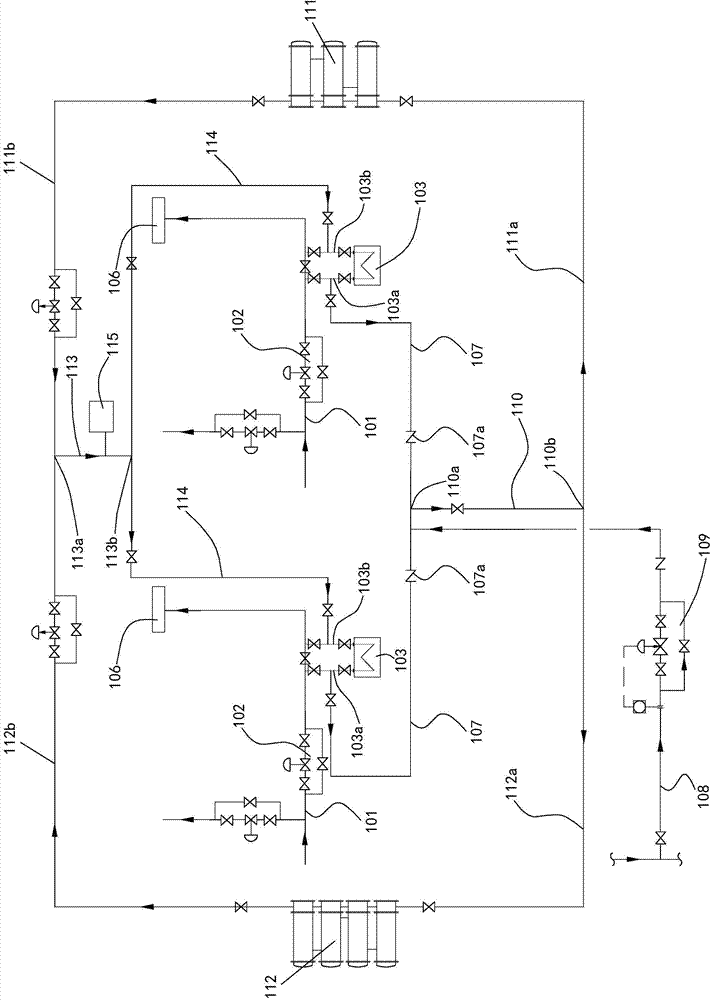

[0028] Such as figure 2The heat combined low-temperature heat recovery system of the petrochemical mid-span device shown, the system includes a low-pressure heat exchanger 103, an inlet water main pipe 110, a return water main pipe 113, a diesel heat exchanger 111, a kerosene heat exchanger 112, and a diesel heat exchanger 111 and kerosene heat exchanger 112 are shell-and-tube heat exchangers, three diesel heat exchangers 111, three diesel heat exchangers 111 connected in series, four kerosene heat exchangers 112, four kerosene heat exchangers 112 in series, the low-pressure heat exchangers 103 are two with the same structure, the two low-pressure heat exchangers 103 are arranged in parallel, each low-pressure heat exchanger 103 has an inlet pipe 103a and an outlet pipe 103b, and the low-pressure heat exchanger 103 The water inlet pipe 103a is connected to the condensed water pipeline 101 of the steam turbine, and the condensed water from the steam turbine is received through...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap