Turbocharged engine with cooling exhaust recirculation technology

A technology of exhaust gas recirculation and turbocharging, which is applied in the direction of exhaust gas recirculation, engine components, combustion engines, etc., can solve the problems that the compression ratio cannot be infinitely increased, restricting the development of supercharged engine technology, etc., and achieves low manufacturing cost and good performance. Fuel economy, rational design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

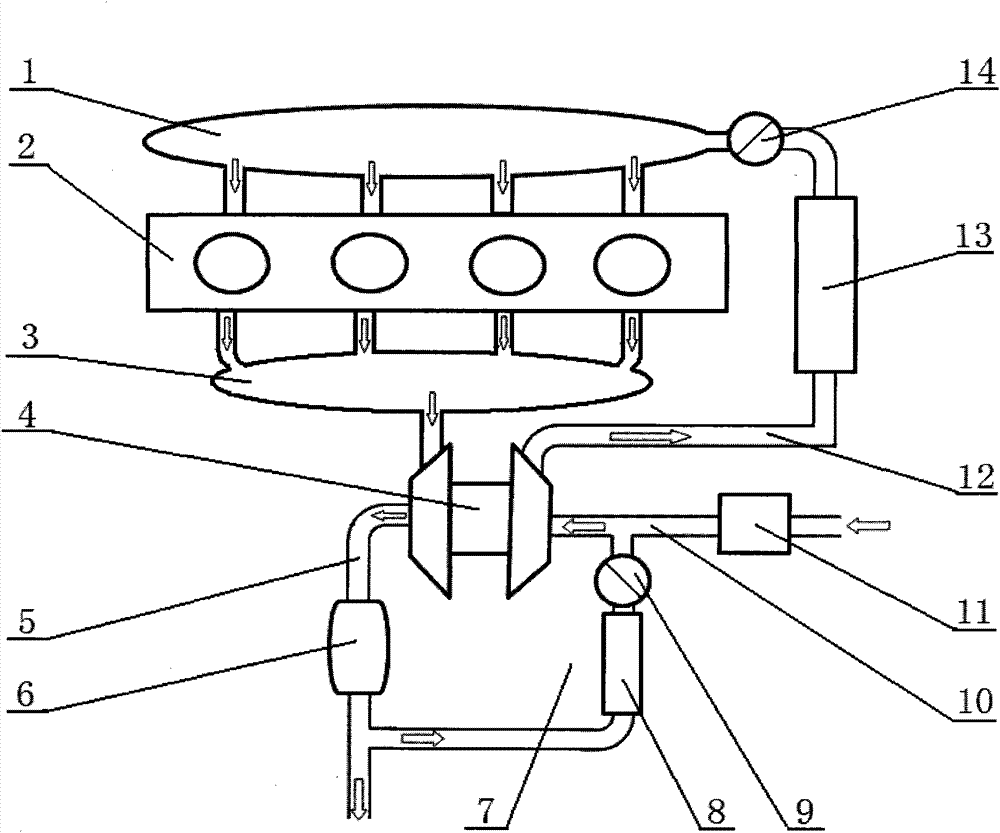

[0011] Depend on figure 1 As can be seen, the present invention comprises engine cylinder head 2, intake manifold 1, exhaust manifold 3, turbocharger 4, and the air inlet of turbocharger 4 vortex ends is connected with exhaust manifold 3, and air outlet passes exhaust manifold 3. The air pipe 5 is connected to the atmosphere, the air inlet of the pressure end of the turbocharger 4 is connected to the air filter 11 through the first air inlet pipe 10, and the air outlet is connected to the throttle valve communicated with the intake manifold 1 through the second air inlet pipe 12 The body 14 is connected, the middle part of the exhaust pipe 5 is provided with a three-way catalytic converter 6, the middle part of the second intake pipe 12 is provided with an engine intercooler 13, and the exhaust port end of the exhaust pipe 5 is also passed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com