Method for building advanced manufacturing simulation factory

A construction method and factory technology, applied in teaching models, instruments, educational appliances, etc., can solve the problems of inconvenient training of employees and unscientific production line management, and achieve the effect of advanced concepts, rapid on-site response, and avoid product damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The construction method of the advanced manufacturing simulation factory of the present invention comprises the following steps:

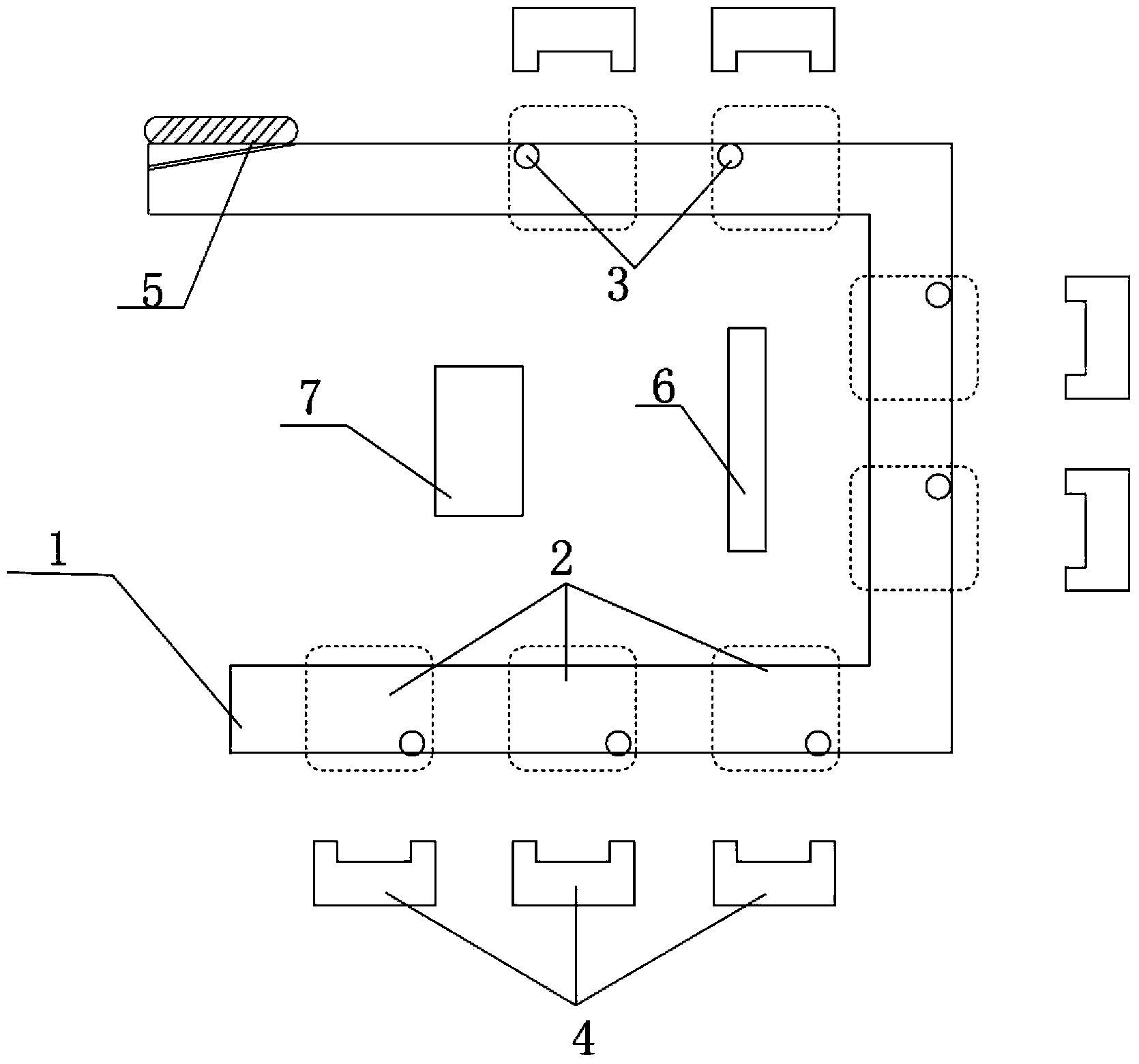

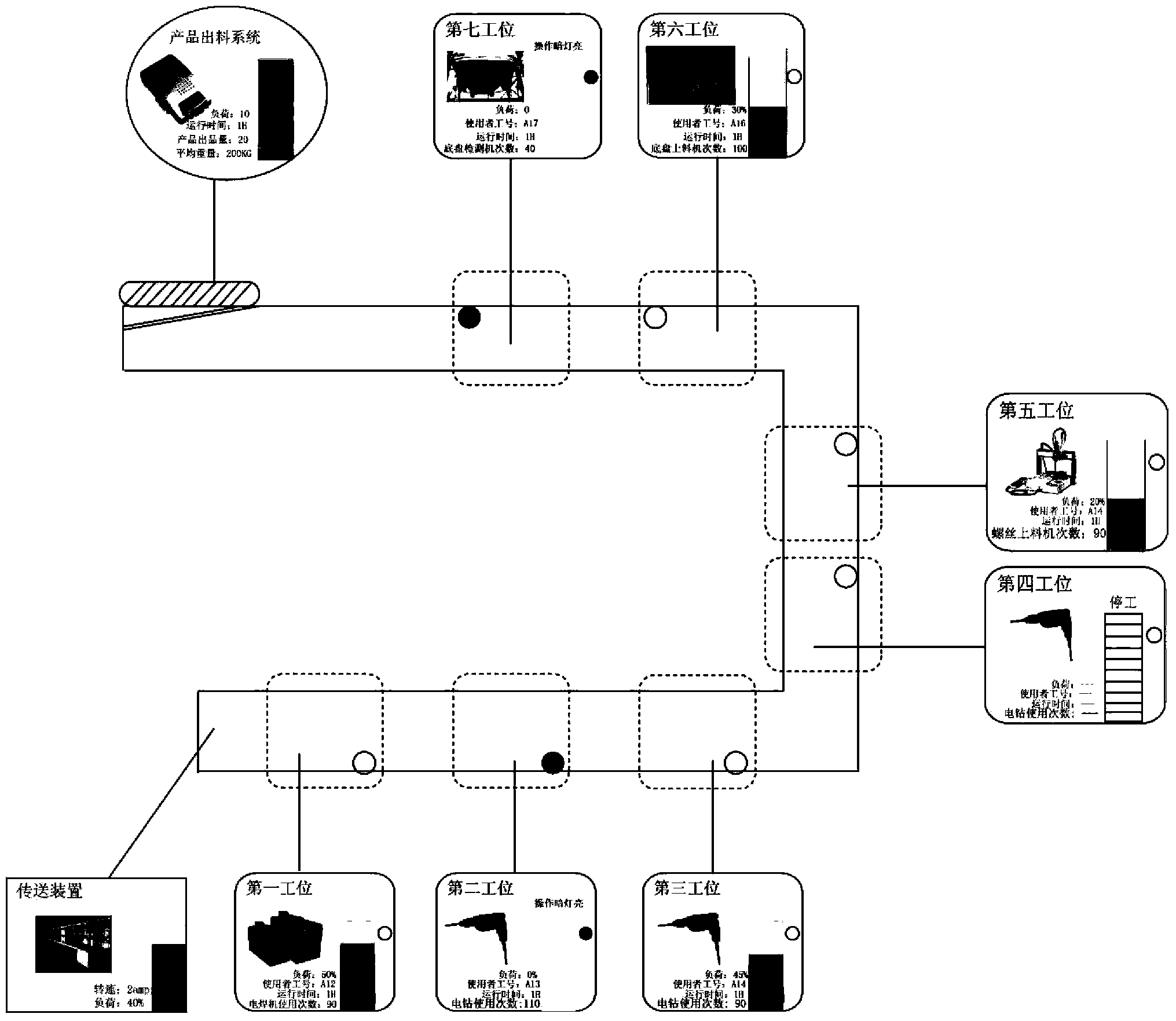

[0036] First, construct a simulated production line: set up a set of simulated production line in the factory building, the simulated production line includes a transmission device 1 and engineering equipment, and set a simulation mold on the transmission device, and then divide the transmission device into a plurality of work stations 2, and The material supermarket 4, engineering equipment, emergency stop button of the conveying device and the dark light system are installed on the operator 2 side, and the product discharge detection system 5 is installed at the end of the simulated production line.

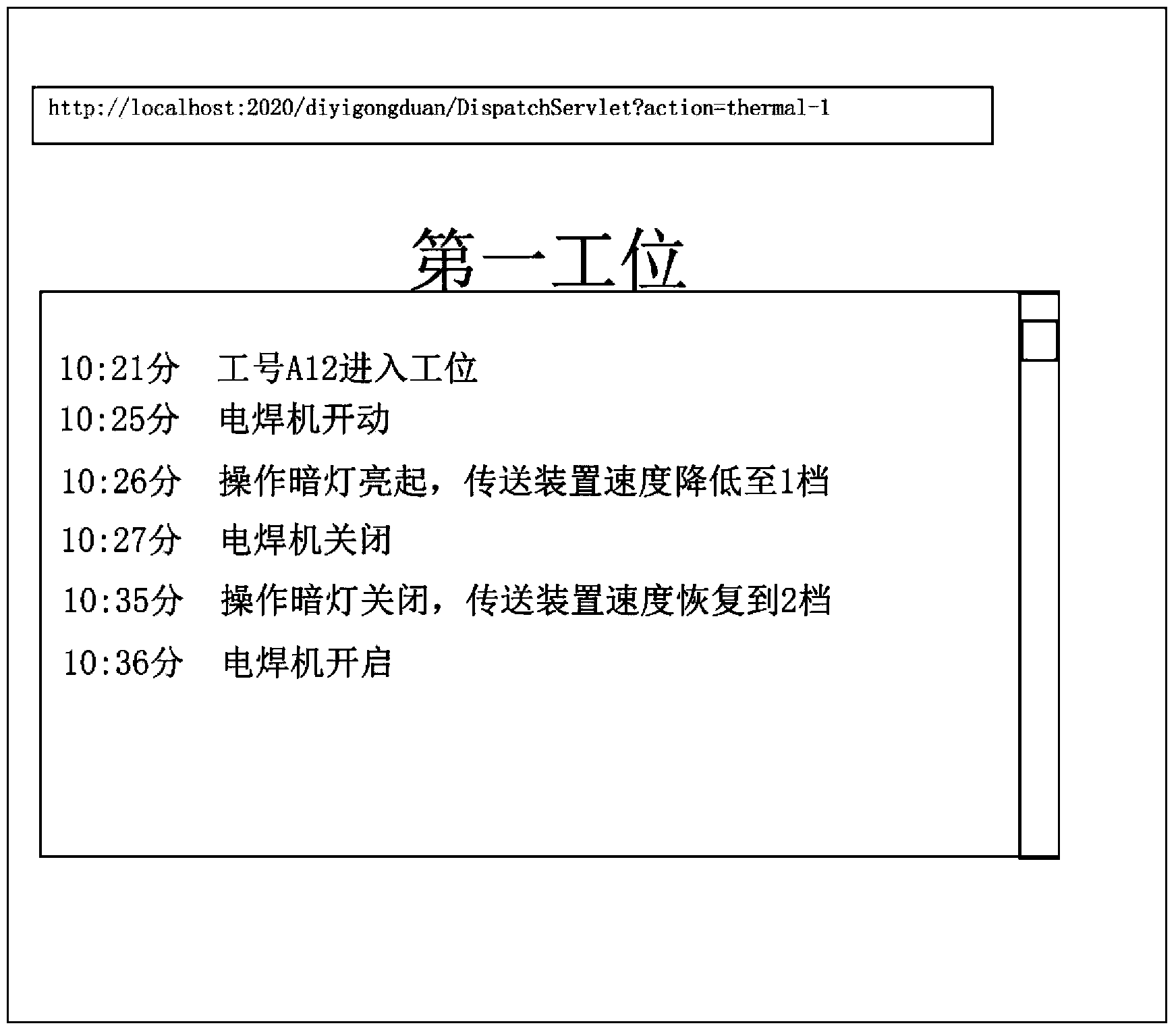

[0037] Secondly, build the information engineering system: set up an electronic kanban 6 for displaying the overview of the simulated production line and MES electronic maps that support all MES application functions, such as dim light systems,...

Embodiment 2

[0055] The difference from embodiment 1 is that the station dark light 3 in the assembly dark light system is a quality dark light, the simulation tool is a wooden mechanical device, and the rest of the working principle is the same as that of embodiment 1.

[0056] In the above-mentioned embodiment, the data interface connection between the on-site server and the analog production line and the engineering equipment can be installed by using existing technology, and the equipment without data interface can be completed by adding electric shock equipment and conventional circuit boards. In order to achieve the effect of operating and connecting to the server. In addition, the independent website construction of the server can be realized by using existing protocols.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com