Method for controlling overcurrent jump stop of high-temperature fan in cement rotary kiln production line pipeline

A technology of cement rotary kiln and control method, which is applied in the direction of motor generator control, AC motor control, electronic reversing motor control, etc., and can solve the problems of airflow disorder in the exhaust pipe, high-voltage frequency converter overcurrent tripping, and increase in dust concentration in the pipeline. Large and other problems, to achieve the effect of good robustness, fast response, and insensitive motor parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

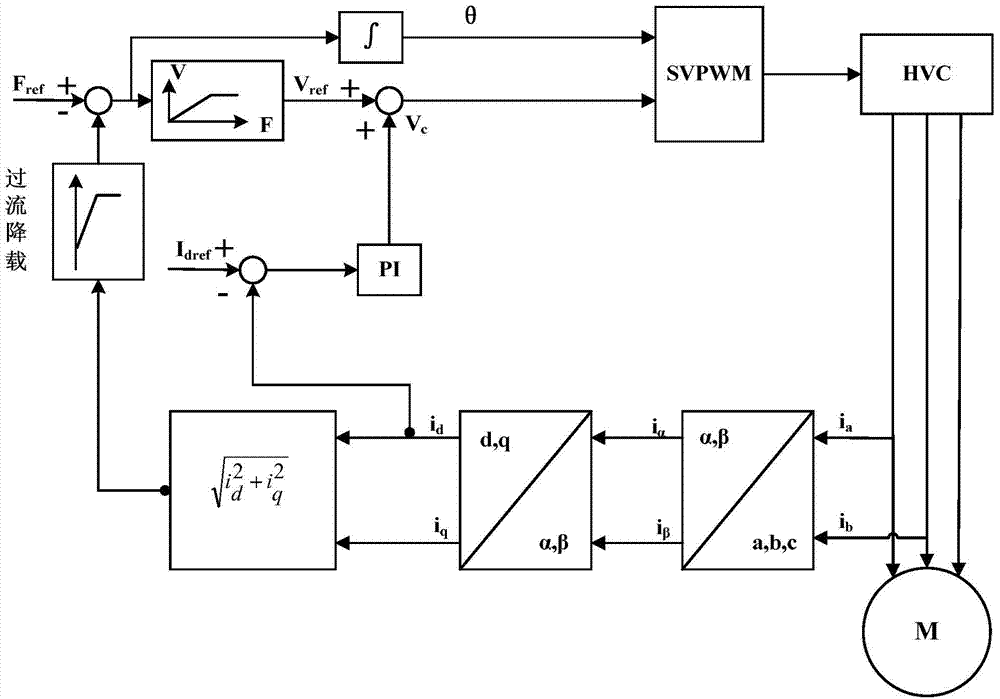

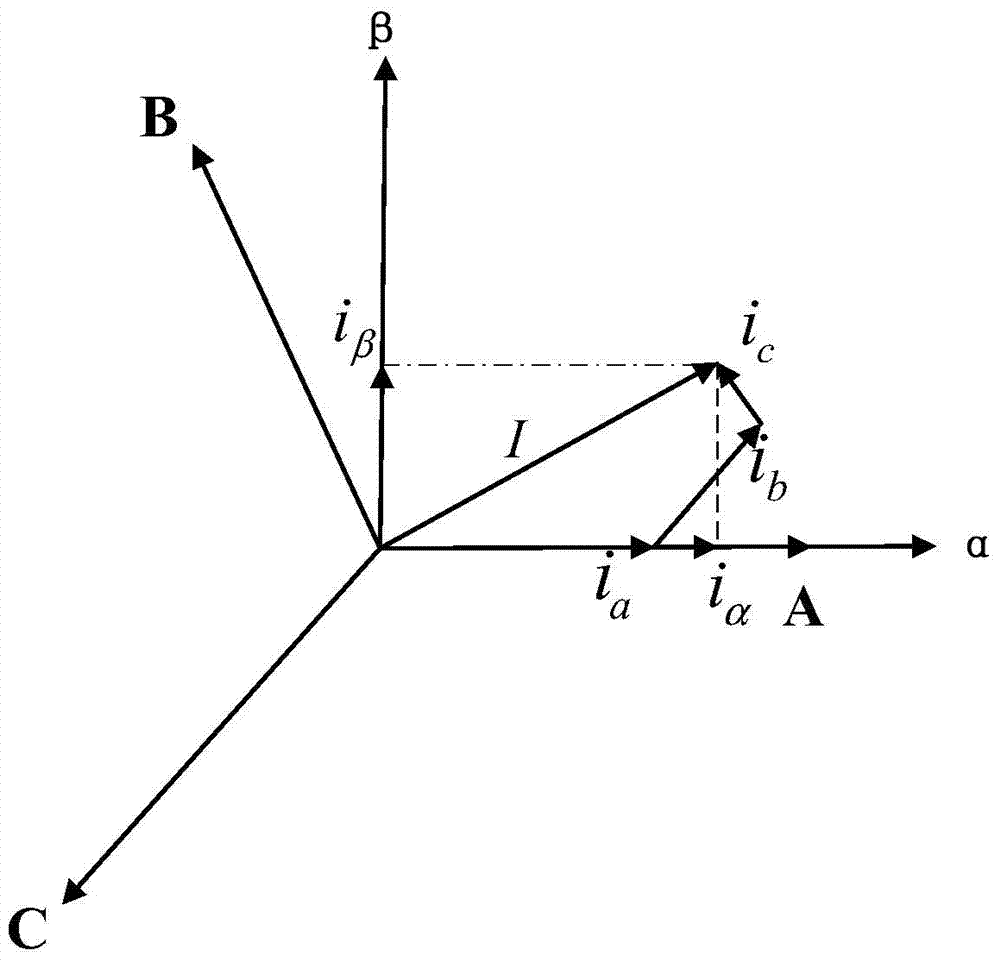

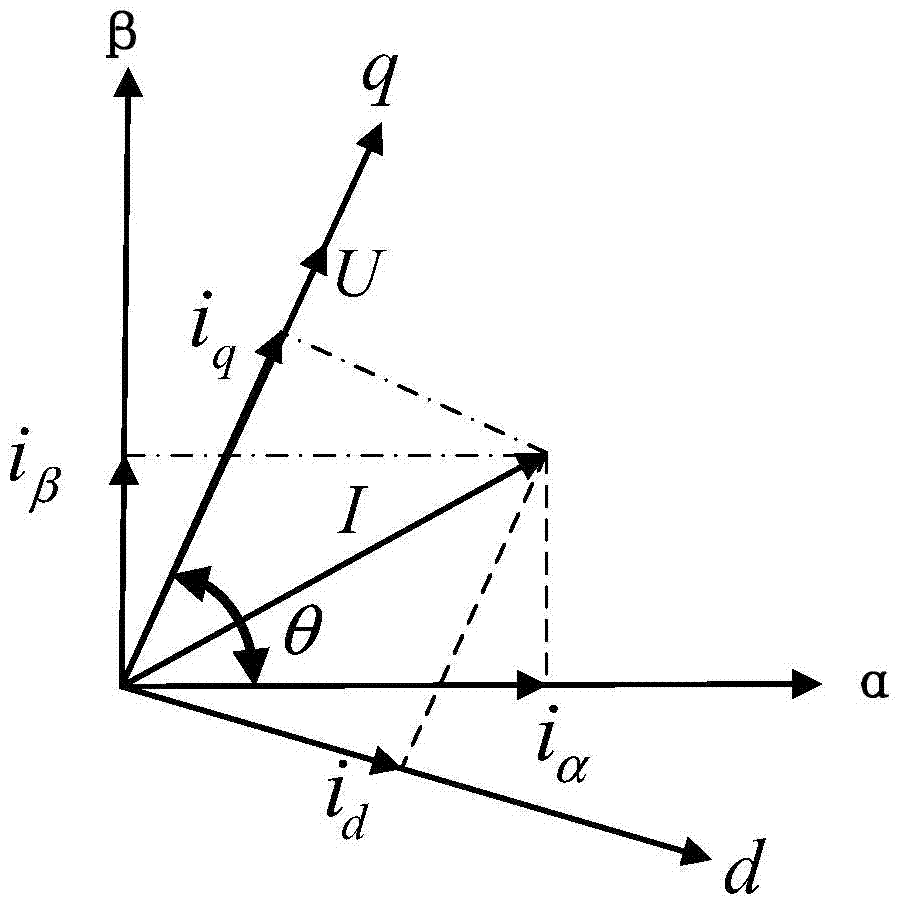

[0028] Such as figure 1 As shown, a control method for over-current tripping of high-temperature fan in the cement rotary kiln production line pipeline of the present invention can control the current and frequency at the same time. The method is as follows: first, the two-phase current of the high-temperature motor is detected by the current sensor, and the detected current is decomposed to obtain the instantaneous active current and the instantaneous reactive current through coordinate transformation; then, the instantaneous reactive current is controlled by the PI regulator, Prevent the inverter from over-current protection due to load changes; at the same time, when the amplitude of the output current of the high-temperature motor is higher than the set value, control the frequency converter to quickly reduce the frequency, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com