Latex balloon seal accessory and use method

A balloon and latex technology, used in sports accessories, inflatable hollow balls, balls, etc., can solve the problems of labor-intensive, easy to buckle the cord, easy to leak air and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

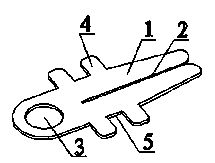

[0117] It is characterized in that: there is one opening crack (2), one connecting hole (3), four positioning stops (4), and two positioning grooves (5) on the geometric body (1);

[0118] Geometry (1) thickness 1.2mm, maximum width 9mm, maximum length 16mm, distance between groove bottoms 5mm; opening gap (2) length 10.25mm; connection hole (3) diameter 3mm; positioning block (4) height 2mm, width 1.5mm mm; the width of the positioning groove (5) is 1.5mm; the material is made of plastic, and the processing of the geometry (1) is completed by mold injection (see figure 1 );

[0119] The method of use is: when the latex balloon is fully inflated, pull the balloon mouth into the opening gap (2), tighten it, and fold it around the positioning groove (5) in the middle of a set of positioning stops (4) at an angle of 720° or 900° or 1080° °, then pull the balloon mouth into the opening gap (2) (see Figure 80 ~ Figure 82 ), rely on the elastic force of the latex balloon mouth t...

Embodiment 2

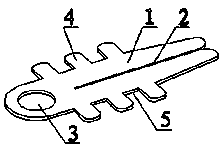

[0121] It is characterized in that: there is one opening crack (2), one connecting hole (3), six positioning stops (4), and four positioning grooves (5) on the geometric body (1);

[0122] The geometric body (1) has a thickness of 2.5mm and a maximum length of 18.5mm; the opening gap (2) has a length of 12.5mm; the material is made of wood veneer, which is completed by laser numerical control cutting, and other dimensions and usage methods are the same as in Example 1 (see figure 2 ).

Embodiment 3

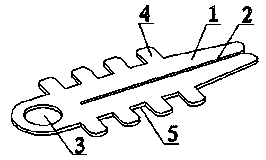

[0124]It is characterized in that: there is one opening crack (2), one connecting hole (3), eight positioning stops (4), and six positioning slots (5) on the geometric body (1);

[0125] The geometry (1) has a thickness of 2.0mm and a maximum length of 21.5mm; the opening gap (2) has a length of 15.5mm; the material is made of bamboo slices, which are cut by laser numerical control, and other dimensions and usage methods are the same as those in Example 1 (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com