Desulfurized gypsum based antistatic self-leveling mortar and its preparation method

A technology for self-leveling mortar and desulfurization gypsum, which is applied in the fields of building materials and functional materials, can solve the problems of unutilized, accumulation and storage of desulfurized gypsum, etc., and achieves the effects of long construction time, saving engineering cycle, and easy control of product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

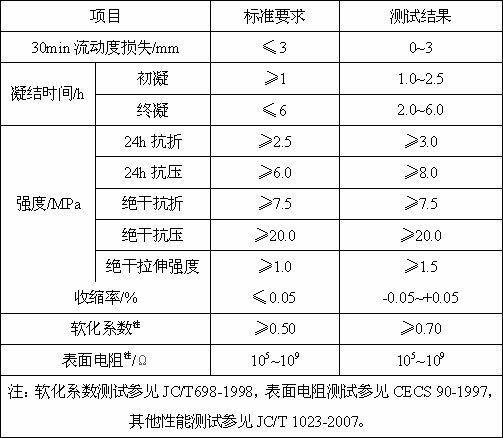

[0021] Example 1: Desulfurization gypsum-based antistatic self-leveling mortar for non-humid parts, its components and proportions (weight percentages) are: desulfurization gypsum: 41.2%, slag powder: 7.5%, fly ash: 3.5%, Portland cement: 5.5%, quartz sand: 21.4%, steel slag sand: 18.0%, modified carbon fiber: 0.15%, redispersible latex powder: 0.84%, cellulose ether: 0.04%, water reducer: 0.15%, Defoamer: 0.18%, early strength agent: 1.5%, retarder: 0.04%, modified carbon nanotube: 0.0035%. The performance results obtained by the detection test are shown in Table 2.

[0022] Table 2 Performance test results of desulfurized gypsum-based antistatic self-leveling mortar in Example 1

[0023]

Embodiment 2

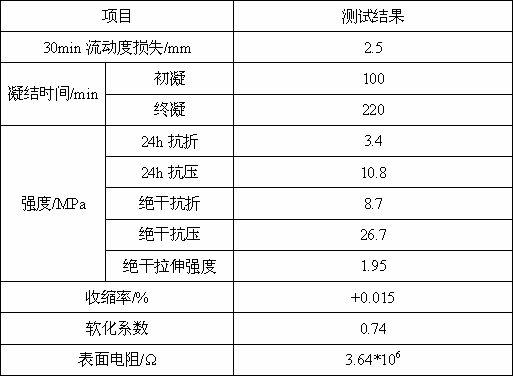

[0024] Example 2: Desulfurized gypsum-based antistatic self-leveling mortar that can be used in relatively humid parts, its components and proportions (weight percentages) are: desulfurized gypsum: 34.6%, slag powder: 7.5%, fly ash: 4.4% , Portland cement: 9.6%, quartz sand: 20.1%, steel slag sand: 20.1%, modified carbon fiber: 0.11%, redispersible latex powder: 0.95%, cellulose ether: 0.032%, water reducer: 0.17% , Defoaming agent: 0.23%, early strength agent: 2.13%, retarder: 0.04%, modified carbon nanotube: 0.0017%. The performance results obtained by the detection test are shown in Table 3.

[0025] Table 3 Performance test results of desulfurized gypsum-based antistatic self-leveling mortar in Example 2

[0026]

[0027] It can be seen from the above examples that the desulfurized gypsum-based antistatic self-leveling mortar proposed by the present invention can be formulated into corresponding products according to the requirements of construction projects. All perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com