Thick plate welding defect removal machine

A technology for welding defects and cleaning machines, which is applied to machine tools, grinders, and metal processing equipment suitable for grinding the edges of workpieces. It can solve the problems of narrow and deep defect locations, and achieve the effect of strong versatility and obvious cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

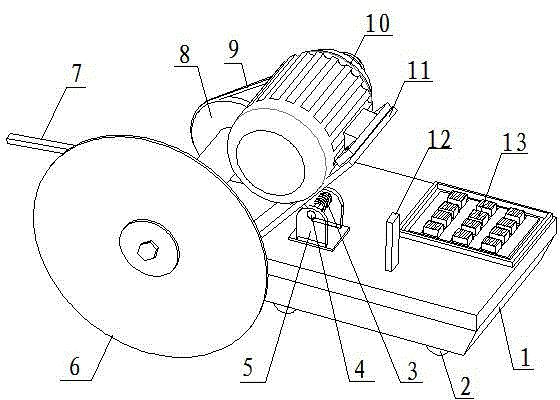

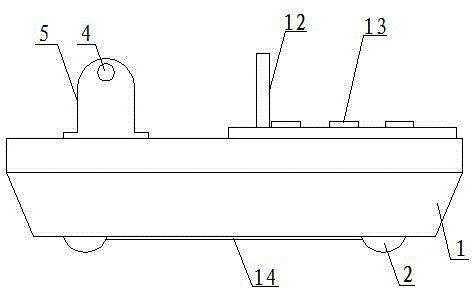

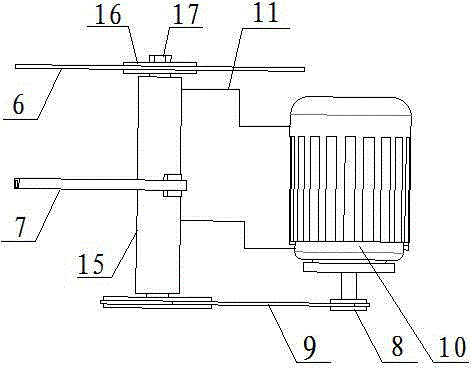

[0022] see figure 1 , figure 2 The thick plate welding defect cleaning machine described in this embodiment is composed of two parts: a traveling mechanism and a cleaning mechanism. The main body of the traveling mechanism is a moving trolley 1, and the lower part of the moving trolley 1 is equipped with an electromagnet 14 and a traveling small wheel 2. , the car body top of mobile trolley 1 is provided with control panel button 13 and the fall-back support 12 of cleaning mechanism, and the function of electromagnet 14 is that whole cleaning machine is fixed on the workpiece to be cleaned in cleaning machine working process, and walking small wheel 2 Controlled by a variable speed motor, the traveling mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com