Secondary mixing type annular rotating grinding material jet flow nozzle

A secondary mixing and abrasive jet technology, applied in abrasives, spray guns, metal processing equipment, etc., can solve the problems of reducing pipeline stability, shortening service life, and poor cutting effect, and achieves improved conveying capacity, improved mixing degree, good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is vertically arranged when in use, and the specific implementation manner of the present invention will be further described below in conjunction with the state of the present invention in use and the accompanying drawings.

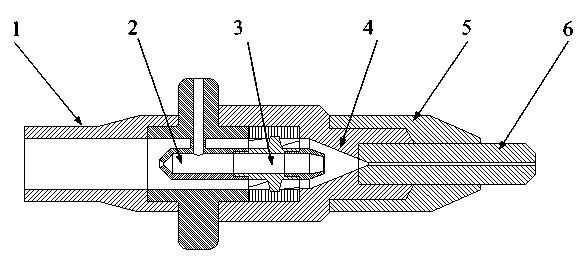

[0032] See figure 1 , this specific implementation includes a high-pressure water supply pipe 1, a primary mixing chamber 2, a flow guide device 3, a secondary mixing chamber 4, a protective cover 5 and an abrasive nozzle 6, a high-pressure water supply pipe 1, a primary mixing pipe 2, a flow guide device 3, and two The secondary mixing chamber 4 and the abrasive nozzle 6 are connected in sequence, and one end of the protective sleeve 5 is connected to the outside of the secondary mixing chamber 4 through a thread, and the other end is connected to the outside of the abrasive nozzle 6 through a thread to fix the abrasive nozzle 6 and the secondary mixing chamber 4 , can also protect the abrasive nozzle 6.

[0033] One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com