Novel automobile braking energy recycling device

An energy recovery and vehicle braking technology, applied in the direction of brakes, braking components, vehicle components, etc., can solve problems such as energy loss and waste, and achieve the effects of extending service life, low temperature, and less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

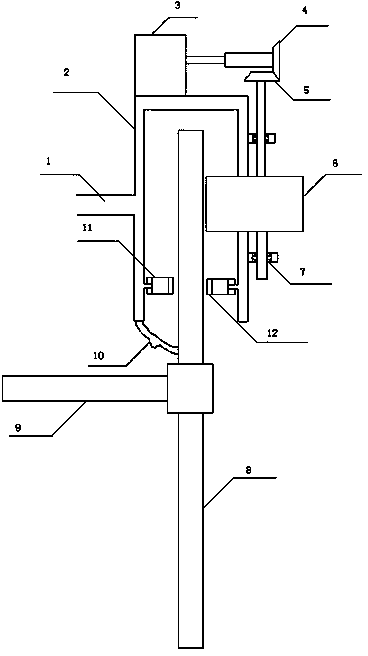

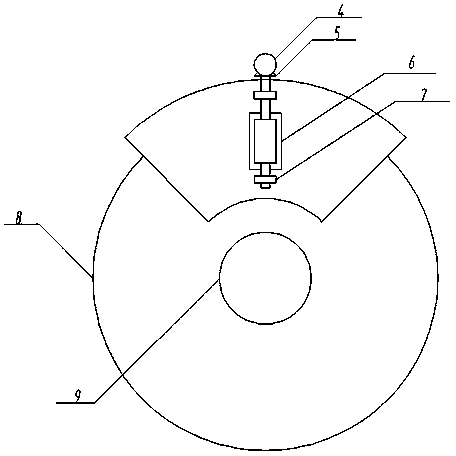

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] like figure 1 , figure 2 As shown, the present invention installs friction wheel 6 on the outside of brake caliper body 2, installs piston 11 and friction block 12 between the inboard of brake caliper body 2 and the slit of brake disc 8, piston 11 and brake caliper body The inner sides of 2 are in contact with each other. When braking, the brake oil enters the two hydraulic chambers in the caliper body 2 through the oil inlet 1, and presses the friction blocks 12 on both sides to the brake disc 8 through the movement of the piston 11, and then Install generator 3 on the top outer side of brake caliper body 2, first bevel gear 4 is installed on the extension shaft of generator 3, friction wheel 6 is connected with second bevel gear 5 by rolling bearing 7, simultaneously first The bevel gear 4 meshes with the second bevel gear 5 to drive the generator to generate el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com