Method for manufacturing water permeable brick from waste concrete, and pavement method of water permeable brick

A technology of discarded concrete and permeable bricks, which is applied to pavements, roads, buildings and other directions paved with prefabricated blocks, which can solve the problems of easy waterlogging, inability to absorb internally, and poor water seepage capacity of urban ground, so as to reduce waterlogging and pollution The effect of reducing the content of matter and reducing the ground temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

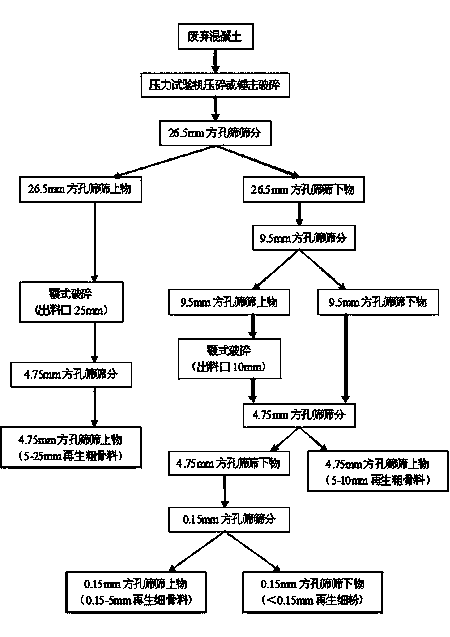

[0029] Embodiment 1: as figure 1 As shown, the method for making permeable bricks from waste concrete is characterized in that it comprises the following production steps:

[0030] (1) After the waste concrete is crushed or hammered by a pressure testing machine, it is screened through a square hole sieve with an aperture of 26.5 mm to obtain the oversize and undersize of the square hole sieve with an aperture of 26.5 mm;

[0031]① Firstly, crush the material on the square-hole sieve with an aperture of 26.5mm using a jaw crusher, and the discharge port of the jaw crusher is 25mm wide; then sieve through a square-hole sieve with an aperture of 4.75mm to obtain The sieve on the square hole sieve with a hole diameter of 4.75mm is the continuous particle size recycled coarse aggregate with a particle size of 5-25mm;

[0032] ②In addition, the undersize of the square hole sieve with an aperture of 26.5mm is sieved with a square hole sieve with an aperture of 9.5mm to obtain the ...

Embodiment 2

[0043] Embodiment 2: Different from Example 1, in the method for making permeable bricks from waste concrete, the calcite is crushed to a particle size of 3mm, and xanthan gum and water are mixed into a glue with a weight ratio of 1:20, and Immerse calcite particles with a particle size of 3mm in the glue solution, then filter the soaked calcite particles through a 10-mesh sieve to remove excess glue solution, and dry them at 25°C for 1.2 hours to form calcite particles wrapped with a glue layer on the outer surface ; Then in step (2), add calcite granules accounting for 4% by weight of cement to the mixer, and stir together with recycled aggregate, water and cement at a temperature of 60°C and a humidity of 30% at a horizontal speed of 1100rpm for 45 Seconds; then enter step (3), after the mixed material after mixing is machine-pressed to make bricks, immerse the bricks in water, then change the water every 10 minutes, repeat 4 times; dry the soaked bricks, Calcite was decomp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com