Method for preparing organosilicone monomer emulsion

A monomer emulsion and silicone technology, applied in the field of preparation of silicone monomer emulsion, can solve the problems of coagulation, easy oil bleed, poor stability, etc., and achieve the effects of less dosage, strong emulsifying ability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

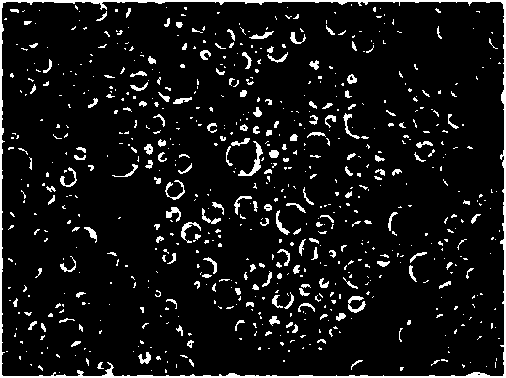

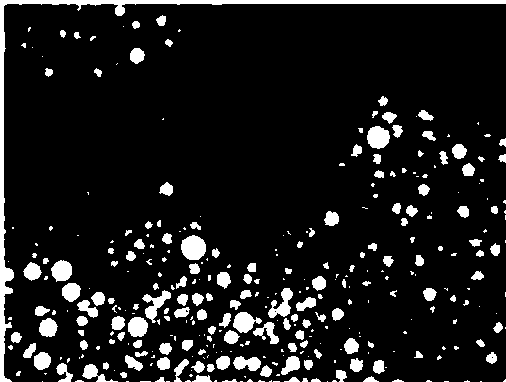

Image

Examples

Embodiment 1

[0024] Add emulsifier (0.2 g sodium dodecylbenzene sulfonate and 0.2 g fatty alcohol polyoxyethylene ether), co-emulsifier (0.1 g glycerol) and 0.1 g water into a 500 mL three-neck flask and stir slowly to mix well , form a uniform emulsion, and then continue to stir and add 40 grams of octamethylcyclotetrasiloxane. The speed of adding octamethylcyclotetrasiloxane is based on the fact that no free silicone oil is produced. After forming a translucent gel, add 40 grams of octamethylcyclotetrasiloxane. gram of water, and continued to stir for 0.5 hour to obtain an octamethylcyclotetrasiloxane monomer emulsion.

Embodiment 2

[0026] Add emulsifier (0.5 g sodium dodecylbenzene sulfonate and 0.5 g fatty alcohol polyoxyethylene ether), co-emulsifier (0.1 g glycerol) and 0.1 g water into a 500 mL three-neck flask and stir slowly to mix well , form a uniform emulsion, and then continue to stir and add 40 grams of hexamethyldisiloxane. The speed of adding hexamethyldisiloxane is based on the fact that no free silicone oil is produced. After forming a translucent gel, add 40 grams of hexamethyldisiloxane water, and continue stirring for 0.5 hour to obtain a hexamethyldisiloxane monomer emulsion.

Embodiment 3

[0028] Add emulsifier (0.9 g sodium dodecylbenzene sulfonate and 0.9 g fatty alcohol polyoxyethylene ether), co-emulsifier (0.3 g glycerol) and 0.3 g water into a 500 mL three-neck flask and stir slowly to mix well , form a uniform emulsion, then continue to stir and add 40 grams of dimethylcyclosiloxane. The speed of adding dimethylcyclosiloxane is based on the fact that no free silicone oil is produced. After forming a translucent gel, add 40 grams of dimethylcyclosiloxane water, and continue stirring for 0.5 hour to obtain a dimethylcyclosiloxane monomer emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com