Natural rubber and nitrile rubber blended medical glove and preparation method thereof

A technology of natural rubber latex and nitrile rubber, applied in protective clothing and other directions, can solve the problems of chemical resistance, poor solvent resistance and poor elasticity of gloves, and achieve the effect of soft hand feeling, convenient and comfortable use, and good oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

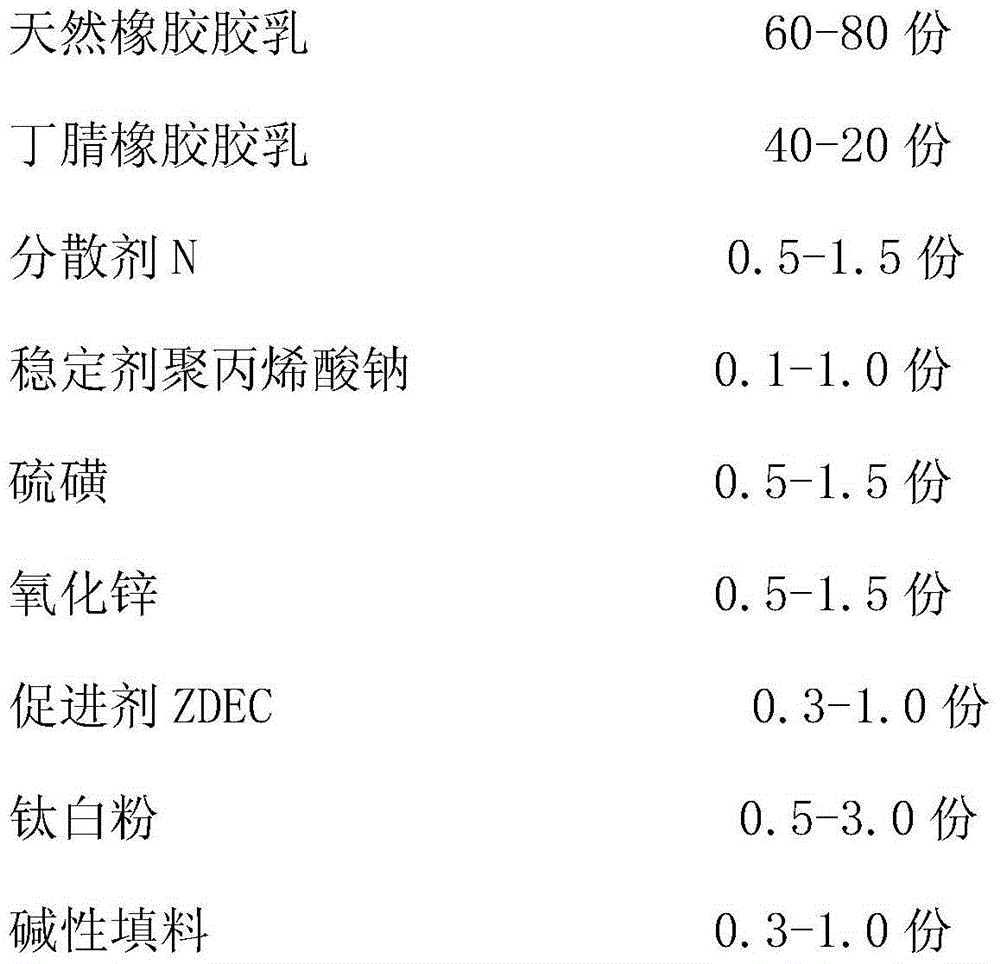

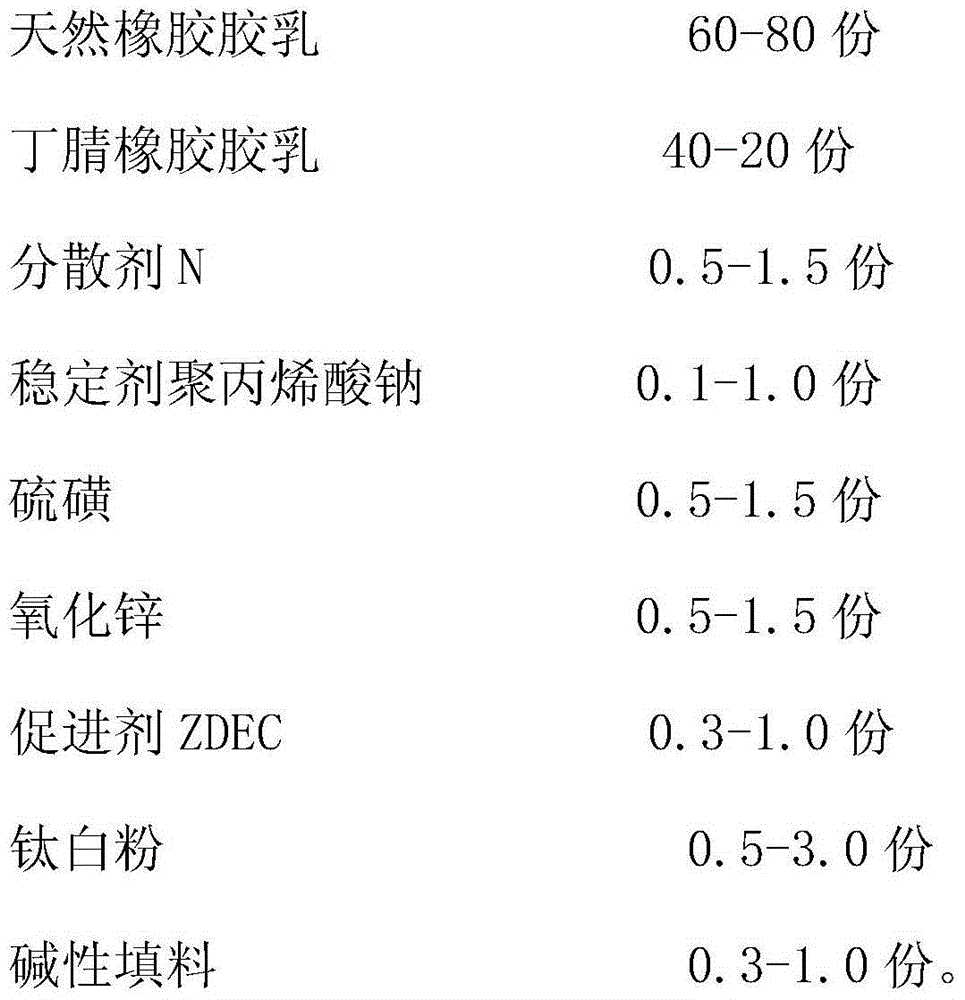

Method used

Image

Examples

example 1

[0016] A preparation method of medical gloves blended with natural rubber and nitrile rubber, the preparation method is as follows: firstly prepare rubber latex for dipping. Take 70 parts of natural rubber latex, 30 parts of nitrile rubber latex, 1.0 part of dispersant N, 0.6 part of stabilizer sodium polyacrylate, and mix well; add 1.0 part of sulfur, 1.0 part of zinc oxide, and 0.7 part of accelerator ZDEC, 1.9 parts of titanium dioxide, 0.6 parts of potassium hydroxide, and adjust the solid content to 28%. After the ceramic mold is cleaned and dried, it is first dipped in a calcium nitrate solution with a concentration of 10% by weight, taken out, dried, and dipped in the latex; then crimped, then immersed in warm water at 45 degrees Celsius for 2 minutes, taken out, and after 30 minutes at 125 degrees Celsius Drying, cooling, and demoulding to obtain the finished product.

Embodiment 1

[0017] The performance data of a kind of nitrile rubber surgical glove prepared in embodiment 1 is as follows, and is detected by the standard of GB10213-2006.

[0018] The performance data of a kind of acrylonitrile-butadiene rubber surgical gloves prepared by the present invention

[0019] Test items

example 2

[0021] A preparation method of medical gloves blended with natural rubber and nitrile rubber, the preparation method is as follows: firstly prepare rubber latex for dipping. Take 65 parts of natural rubber latex, 35 parts of nitrile rubber latex, 0.8 parts of dispersant N, 0.8 parts of stabilizer sodium polyacrylate, and mix well; add 0.6 parts of sulfur, 1.2 parts of zinc oxide, 0.5 parts of accelerator ZDEC, titanium dioxide 1.5 parts, 0.8 parts of potassium hydroxide, and adjust the solid content to 25%. After the ceramic mold is cleaned and dried, it is first dipped in a calcium chloride solution with a concentration of 8% by weight, taken out, dried, and dipped in the latex; then crimped, then immersed in warm water at 50 degrees Celsius for 2 minutes, taken out, and passed through 120 degrees Celsius for 35 minutes Drying, cooling, demoulding, and finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com