Universal color wiper for furniture paint bottom surface coloring and preparation method thereof

A technology for color wipes and furniture paints, applied in the coating and other directions, can solve the problems of restricting the promotion and application of color wipes, residual resin sticking color, weak adhesion, etc., to achieve good wetting primer effect and increase layers effect, good primer wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

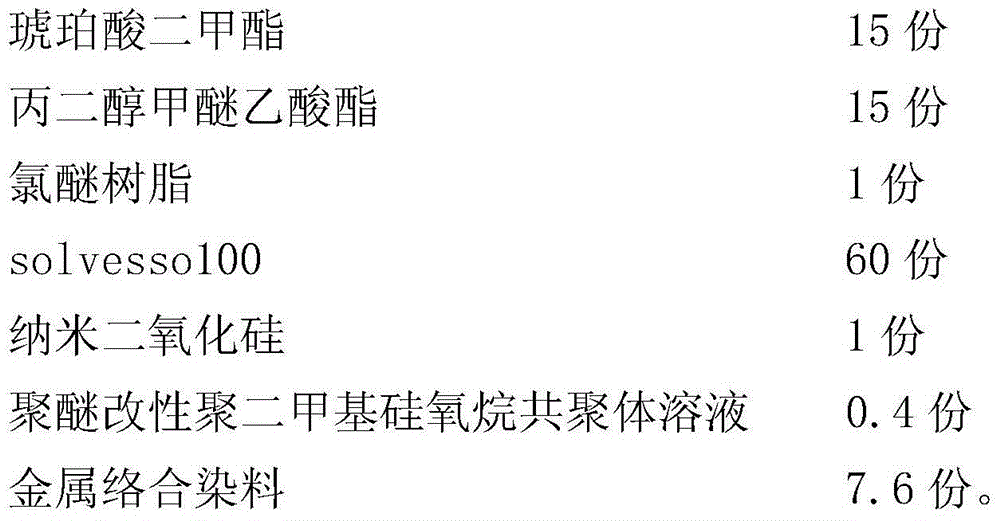

[0030] Embodiment 1 (best embodiment):

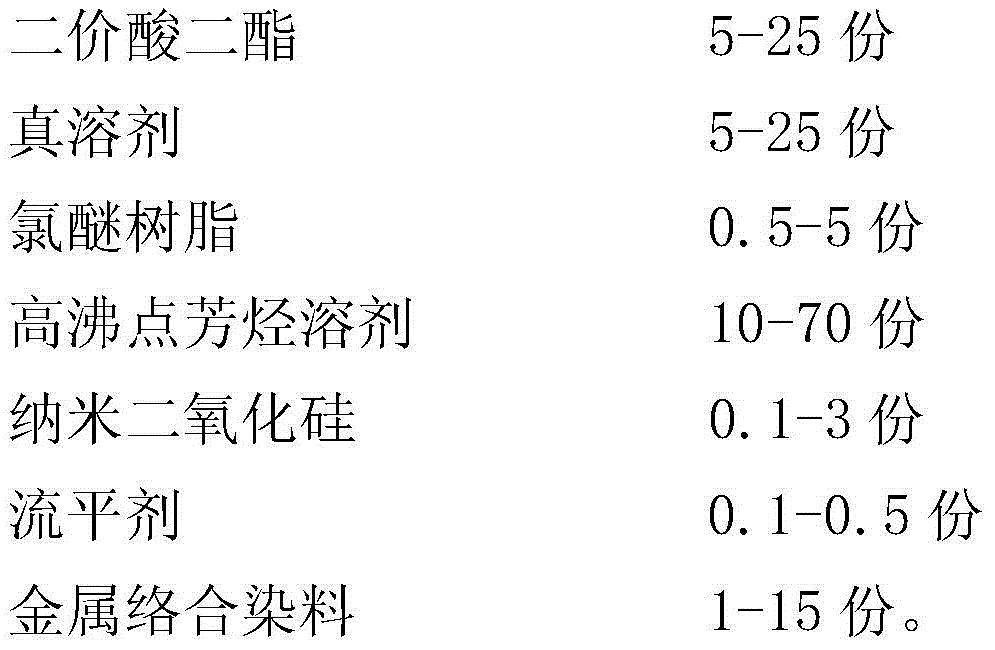

[0031] A general-purpose color wiper for furniture paint bottom surface coloring, prepared from the following raw materials according to the following weight ratio:

[0032]

[0033] The preparation method of the universal color wiper for the coloring of the furniture paint bottom surface comprises the following steps in sequence:

[0034] (1) Add 15 parts of dimethyl succinate, 15 parts of propylene glycol methyl ether acetate, 1 part of chloroether resin and 60 parts of solvesso100 in sequence, then start the disperser and adjust the speed to 700 rpm, disperse for 6 minutes until mixed Uniform;

[0035] (2) At a speed of 700 rpm, add 1 part of nano-silica and 0.4 part of polyether-modified polydimethylsiloxane copolymer solution, then adjust the speed of the disperser to 900 rpm, and disperse for 12 Minutes to fineness <100μm;

[0036] (3) Next, adjust the speed of the disperser to 600 rpm, add 7.6 parts of metal complex dye at ...

Embodiment 2

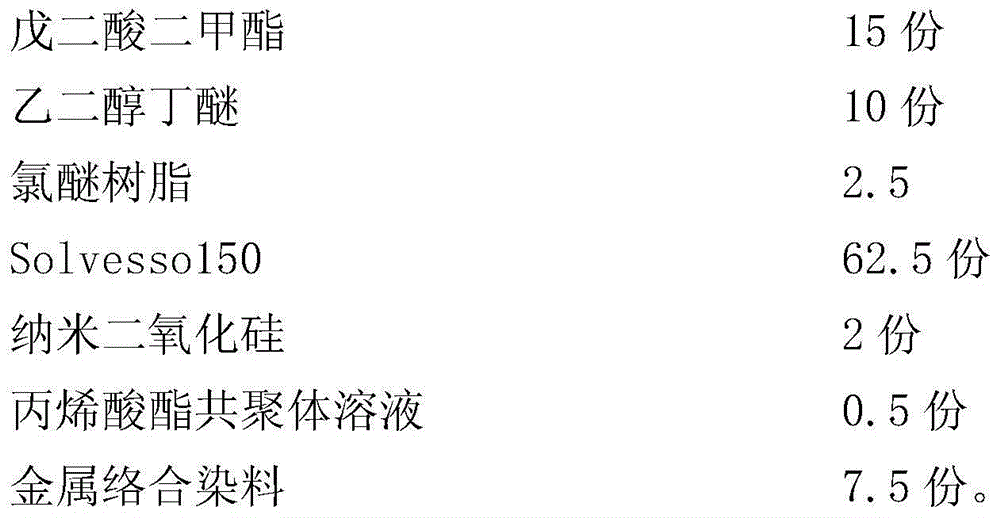

[0038] A general-purpose color wiper for furniture paint bottom surface coloring, prepared from the following raw materials according to the following weight ratio:

[0039]

[0040] The preparation method of the universal color wiper for polishing the bottom surface of furniture paint comprises the following steps in sequence:

[0041] (1) Add 15 parts of dimethyl glutarate, 10 parts of ethylene glycol butyl ether, 2.5 parts of chloroether resin and 62.5 parts of solvesso150 in sequence, then start the disperser and adjust the speed to 600 rpm, disperse for 8 minutes until mixed Uniform;

[0042] (2) At a speed of 600 rpm, add 2 parts of nano-silica and 0.5 parts of acrylate copolymer solution, then adjust the speed of the disperser to 800 rpm, and disperse for 15 minutes until the fineness is <100 μm;

[0043] (3) Then adjust the speed of the disperser to 400 rpm, add 7.5 parts of metal complex dye at this speed, then adjust the speed of the disperser to 600 rpm, and dis...

Embodiment 3

[0045] A general-purpose color wiper for furniture paint bottom surface coloring, prepared from the following raw materials according to the following weight ratio:

[0046]

[0047]

[0048] The preparation method of the universal color wiper for the coloring of the furniture paint bottom surface comprises the following steps in sequence:

[0049] (1) Add 17 parts of dimethyl glutarate, 11 parts of dipropylene glycol methyl ether, 3 parts of chloroether resin and 49 parts of solvesso150 in sequence, then start the disperser and adjust the speed to 800 rpm, and disperse for 5 minutes until the mixture is uniform ;

[0050] (2) At a speed of 800 rpm, add 0.5 parts of nano-silica and 0.5 parts of polyether-modified polydimethylsiloxane interpolymer solution, then adjust the speed of the disperser to 1000 rpm, and disperse for 10 Minutes to fineness <100μm;

[0051] (3) Next, adjust the speed of the disperser to 400 rpm, add 19 parts of metal complex dye at this speed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com